Neutral point clamping type multi-level converter direct current capacitor state detection method

A multi-level converter, neutral point clamp technology, applied in capacitance measurement, measurement of electrical variables, environmental/reliability testing, etc. system and other issues, so as to shorten the test time, consider comprehensively, and ensure the safety of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

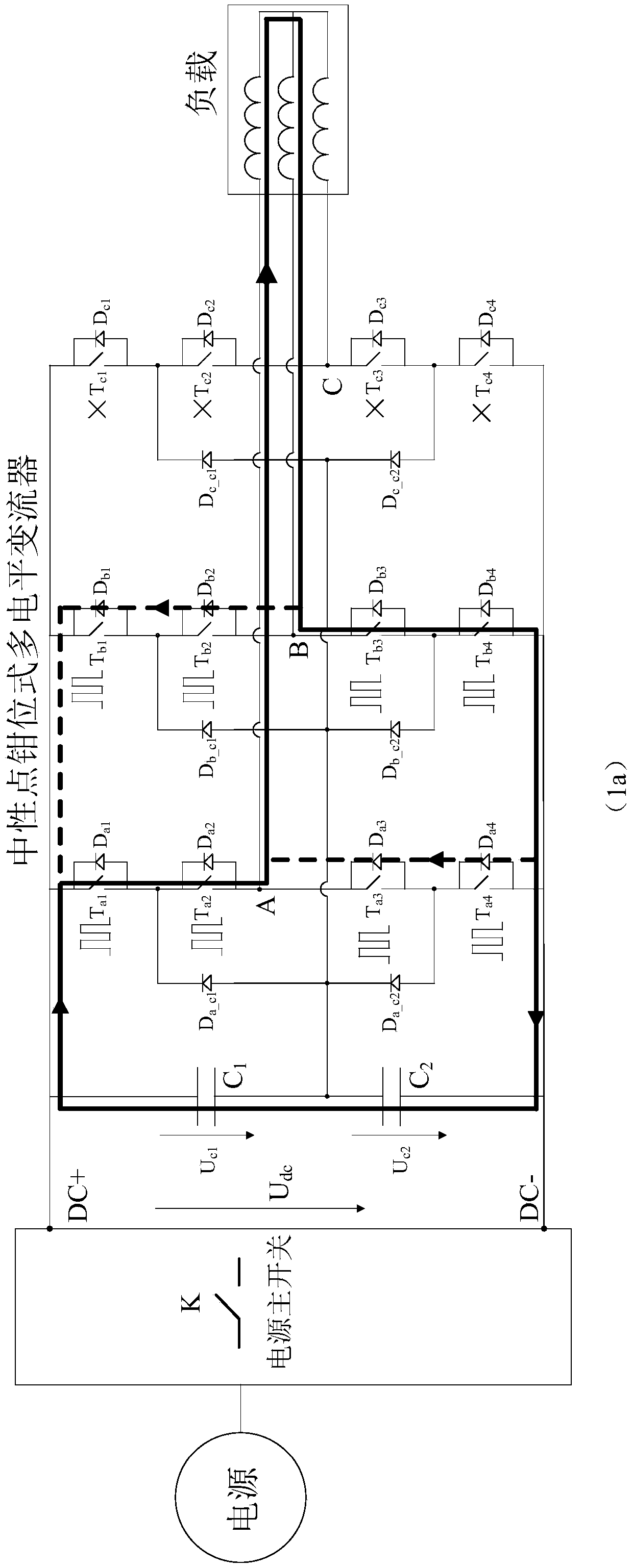

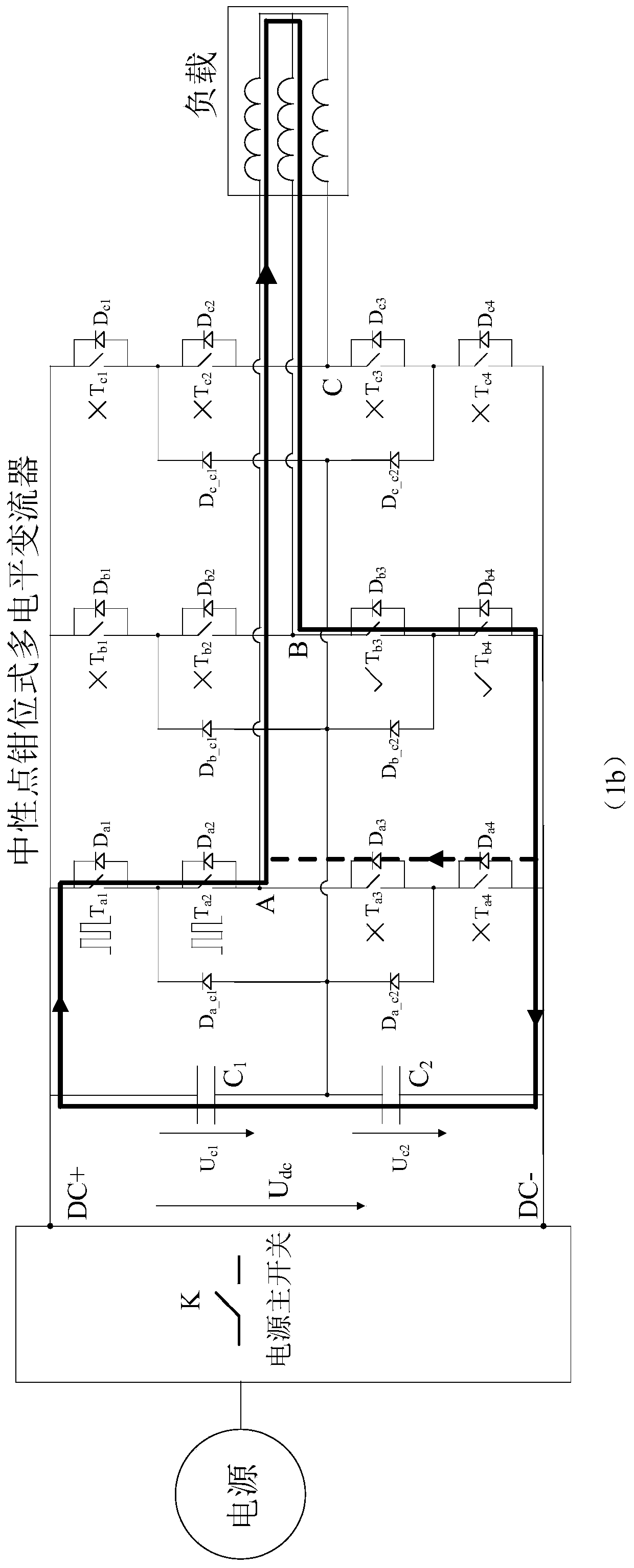

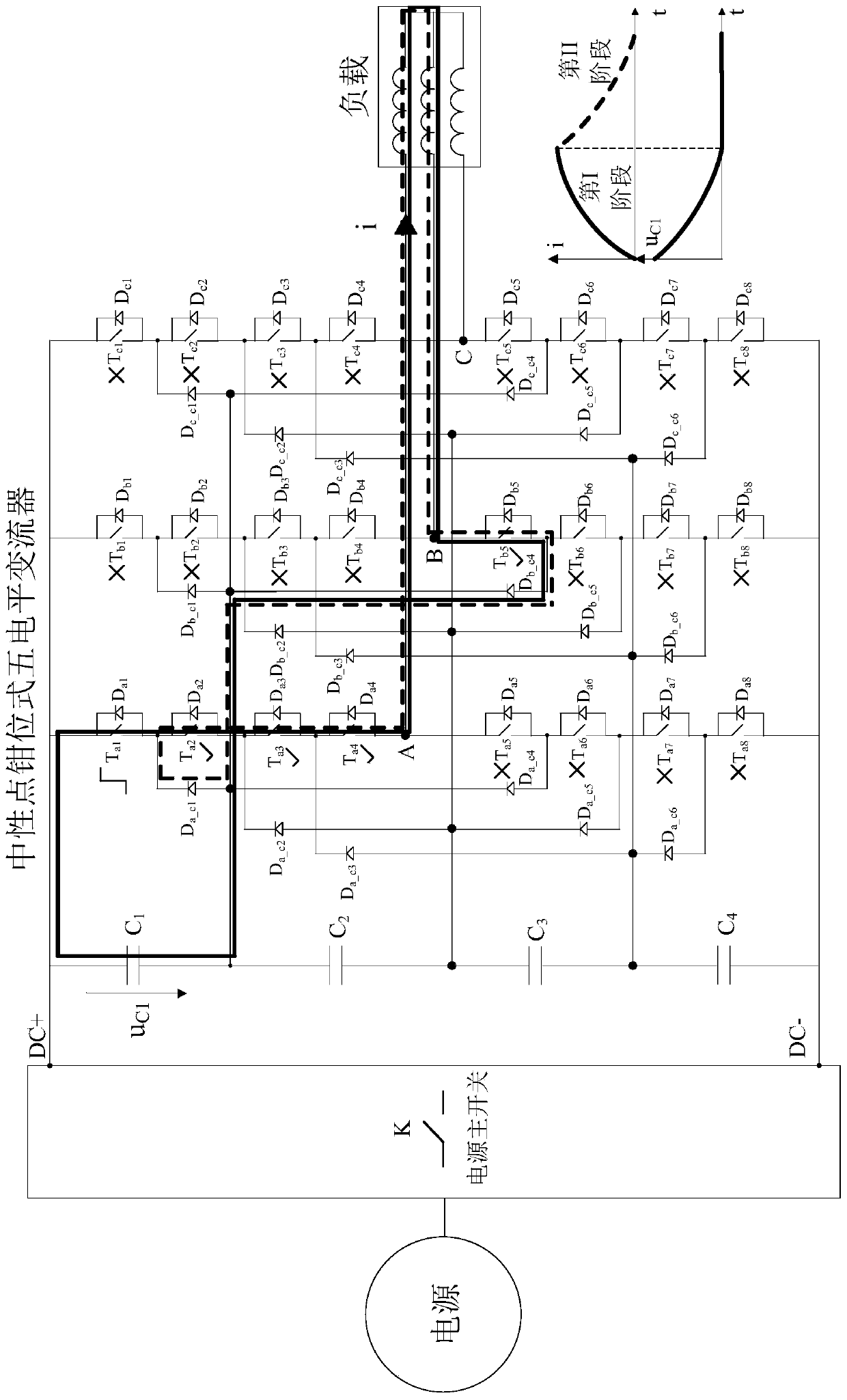

[0070] Embodiment 1: Simulation of DC capacitance detection of CHR2 three-level traction converter of Harmony EMU

[0071] Schematic diagram of CHR2 traction system of Harmony EMU Figure 5 As shown, the parameters are shown in Table 1.

[0072] Table 1 CHR2 Traction System Parameters

[0073]

[0074] The CRH2 traction system uses a pantograph to obtain power from the high-voltage power grid, and then supplies power to two traction converters after being stepped down by the traction transformer. Each traction converter uses a pulse rectifier to rectify single-phase alternating current to direct current, and then converts it to three-phase alternating current through an inverter, and drives four traction motors to provide power for the locomotive. In order to realize high-voltage and large-capacity power conversion and control, the pulse rectifier and inverter in the traction converter adopt a neutral-point clamped three-level converter structure.

[0075] The method pro...

Embodiment 2

[0076] Example 2: 380V / 10kVA neutral point clamped three-level converter DC capacitance detection experiment

[0077] In order to further verify the effectiveness and feasibility of the method of the present invention, a DC capacitance detection experiment was carried out in a 380V / 10kVA neutral point clamped three-level converter experimental system. Such as Figure 8 As shown, the experimental system uses an adjustable DC power supply to supply power to the three-level converter to drive the induction motor to rotate. The motor control adopts the constant current open-loop control mode, and the frequency and current of the converter can be set arbitrarily. The converter adopts Infineon 1.2kV / 30A neutral point clamped three-level IGBT power module (FS3L30R07W2H3F). The main controller of the converter adopts TI DSP28335, and samples the system voltage and current signals through the A / D sampling circuit. The DC capacitor pre-discharge and resonance test control algorithm i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com