Micrometer precise holder motion control device and method

A motion control device and pan/tilt technology, applied in non-electric variable control, position/direction control, control/regulation systems, etc., can solve problems such as inaccurate ranging, not a constant value, and inability to meet precise target positioning. , to achieve the effect of improving repeated positioning accuracy and facilitating accurate aiming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0038] The first purpose of the present invention is to realize the repeatable positioning of the precision pan-tilt, which is conducive to fast aiming at the target, and the second purpose is to ensure that the first condition is met, each time the precise positioning is quickly completed, and the real-time positioning is ensured.

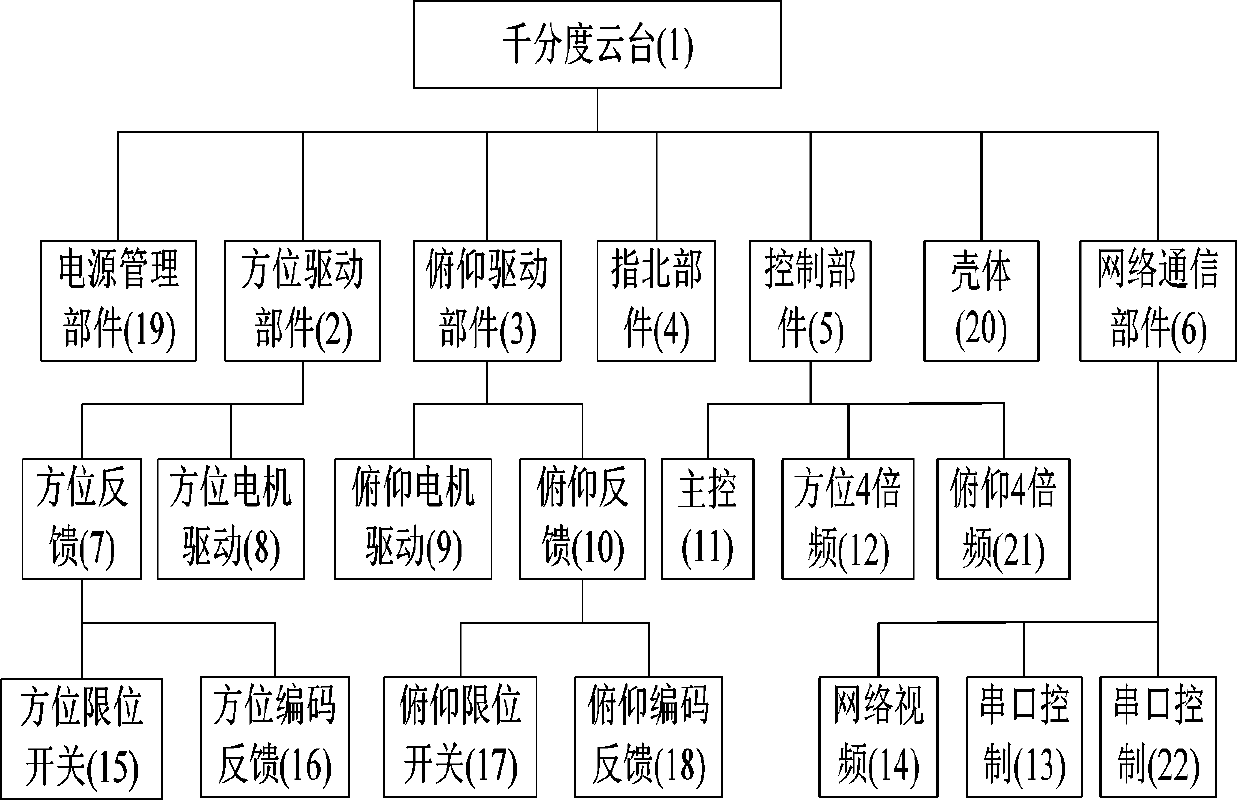

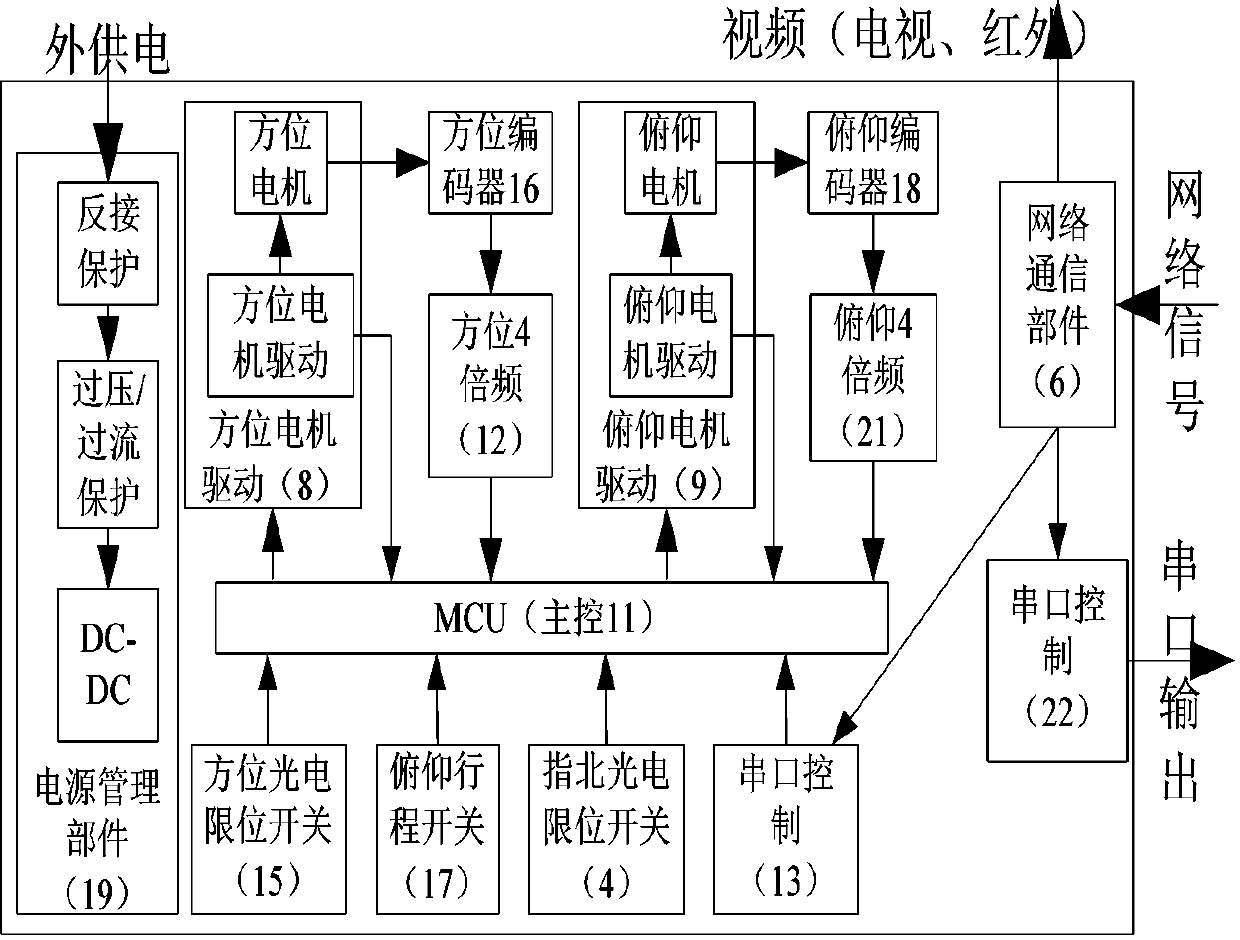

[0039] refer to figure 1 As shown, the micrometer pan / tilt 1 of the present invention is mainly composed of the following components: a power management component 19 , an azimuth drive component 2 , a pitch drive component 3 , a north component 4 , a control component 5 , a network communication component 6 and a housing 20 .

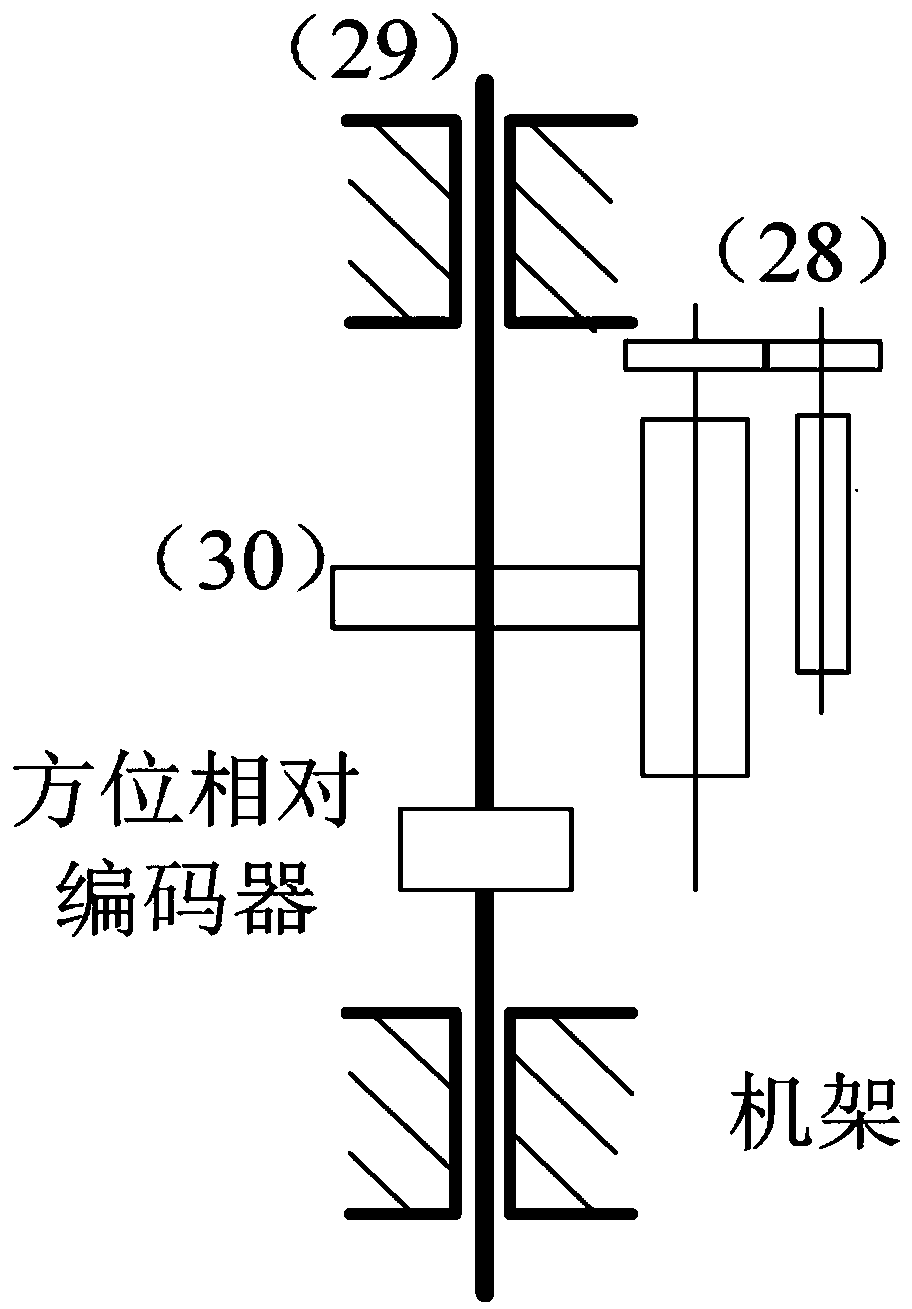

[0040] The azimuth driving part 2 is composed of an azimuth motor 27, an azimuth feedback module 7 and an azimuth motor drive module 8, and the azimuth feedback module 7 is composed of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com