Super-strong anti-slip three-dimensional TPE elastic structure composite carpet and compounding process thereof

A technology of elastic structure and composite technology, which is applied in the direction of carpets, floor coverings, and other household appliances, etc., can solve the problems of not being able to achieve anti-slip effect and non-wear resistance, and achieve good anti-slip and smooth performance, clear texture, and thermal stability good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

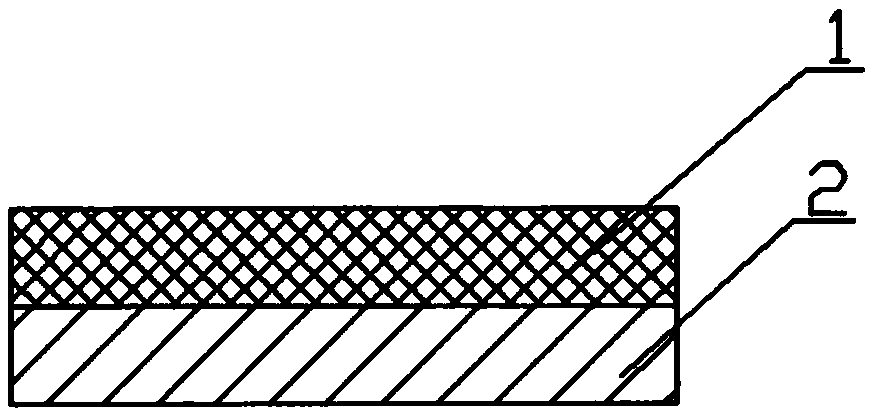

[0019] Embodiment 1: as attached figure 1 As shown, a composite carpet with super strong non-slip three-dimensional TPE elastic structure is composed of fabric layer 1 and TPE layer 2. The TPE is composed of 80-90% styrene-butadiene oxide block copolymer and 10 ~20% polypropylene, and the thickness of the TPE layer 2 is 1~2mm. The bottom surface of the TPE layer 2 is provided with a pattern layer, and the TPE layer 2 and the pattern layer are of an integrated structure. The fabric layer 1 is a polyester fabric layer, a wool fabric layer, a nylon fabric layer or a silk carpet layer.

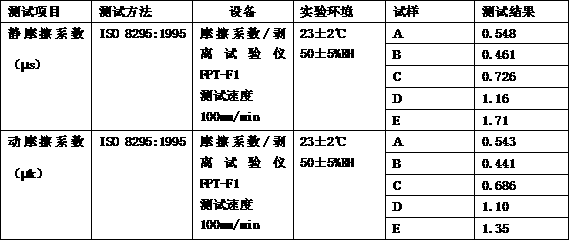

[0020] The following is the friction coefficient test table for 5 kinds of composite carpet samples:

[0021]

[0022] Among them, ABCD is the existing market fabric, E is the composite carpet with super strong anti-slip three-dimensional TPE elastic structure of the present invention, other A is polyester flocking composite carpet, B is polypropylene composite carpet, C is polyester composit...

Embodiment 2

[0030] Embodiment 2: a kind of composite process of super strong non-slip three-dimensional TPE elastic structure composite carpet, comprising the following steps,

[0031] First, preheat the transparent TPE to 80°C, then add it to the barrel of the casting machine, stir the TPE through the screw, heat the heating temperature from 140°C to 200°C in 6 to 9 intervals, and the heated TPE forms Pasty;

[0032] Second, the pasty TPE is extruded into the die through the metal joint; the metal joint is provided with a heating zone;

[0033] Thirdly, pass the pasty TPE in the form of a plane water flow through the die head, and pass through between the printing roller and the rubber roller together with the back of the carpet surface to be compounded at the same time, and compound with the bottom surface of the fabric layer; The 3D three-dimensional stripe roller on the surface of Luo makes the TPE and the carpet surface fit firmly with texture.

[0034] The die head is 2.8 meters l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com