Foam fire extinguishing material containing closed-cell foam ceramic spheres, and preparation method thereof

A closed-cell foam ceramic and foam fire extinguishing technology, applied in fire protection equipment and other directions, can solve the problems of difficult spraying of foam fire extinguishing materials, poor damage resistance of foam covering layers, and short oil surface coverage time, etc., and achieve the best thermal insulation performance. , Long fire resistance time, reducing the effect of tearing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of foam fire extinguishing material that contains closed-cell foam ceramic balls, its component comprises by weight parts: 100g fluoroprotein foam fire extinguishing agent, 100g closed-cell foam ceramic balls and 1000g water.

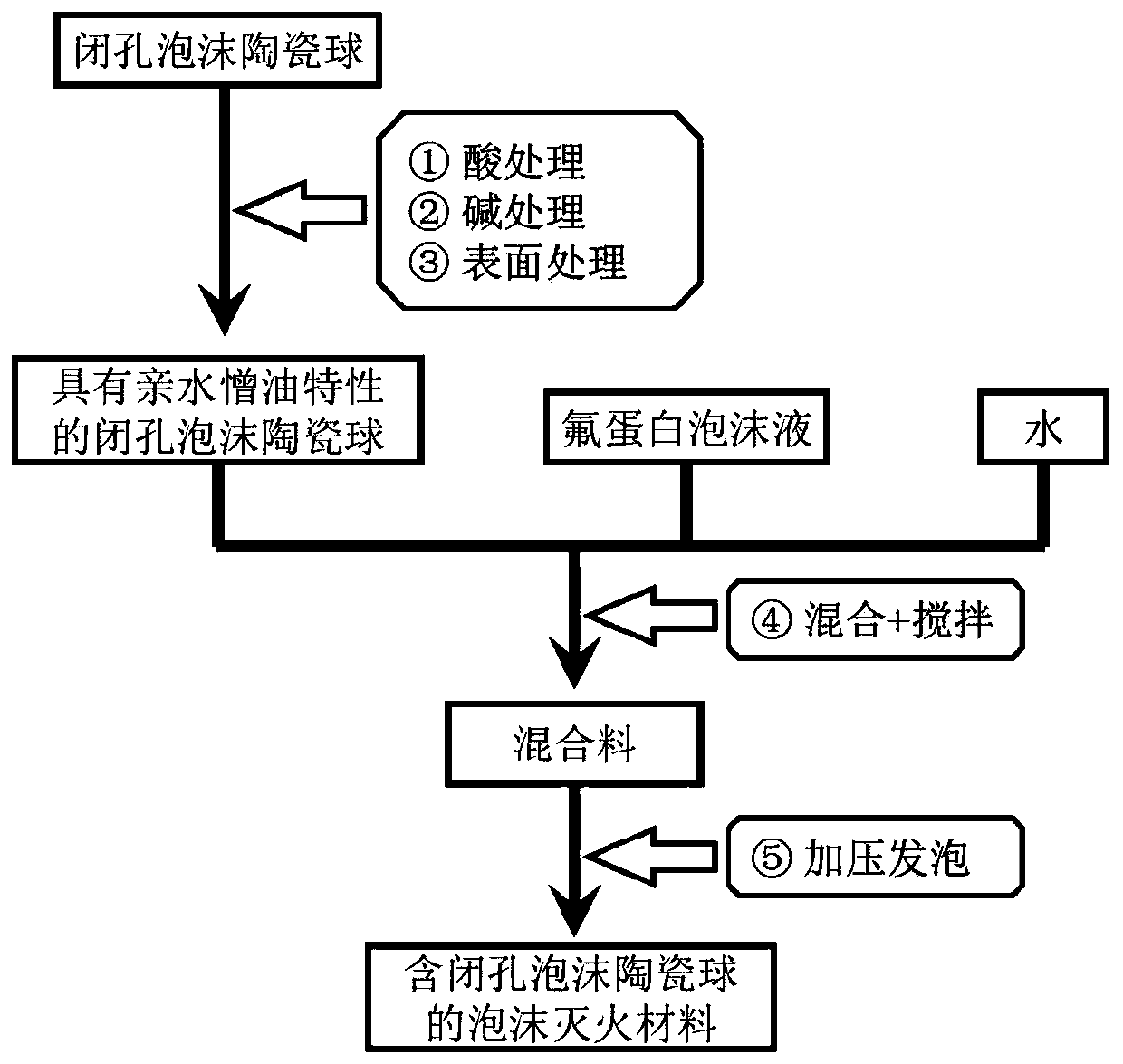

[0026] The preparation method of the above-mentioned foam fire extinguishing material containing closed-cell foam ceramic balls, the steps are as follows:

[0027] (1) Acid treatment: pour 1000mL concentrated sulfuric acid and 400mL, 30wt% hydrogen peroxide into 300g of closed-cell foam ceramic balls, stir the mixture for 20min at a speed of 100-150 rpm, and rinse the closed-cell foam ceramic balls with water ,dry;

[0028] (2) Alkali treatment: Pour 200mL, 25wt% ammonia water, 200mL, 30wt% hydrogen peroxide and 1000mL water into the acid-treated closed-cell foam ceramic ball, heat the mixed solution to 65°C, and use ultrasonic vibration with 100 rpm Stir at a rotating speed of 50 minutes, then filter and dry the closed-cell foam ceramic ...

Embodiment 2

[0033] A kind of foam fire extinguishing material that contains closed-cell foam ceramic balls, its component comprises by weight: 200g fluoroprotein foam fire extinguishing agent, 150g closed-cell foam ceramic balls and 1000g water.

[0034] The preparation method of the above-mentioned foam fire extinguishing material containing closed-cell foam ceramic balls, the steps are as follows:

[0035] (1) Acid treatment: pour 1500mL concentrated sulfuric acid and 600mL, 30wt% hydrogen peroxide into 300g of closed-cell foam ceramic balls, stir the mixture for 30min at a speed of 100-150 rpm, and rinse the closed-cell foam ceramic balls with water ,dry;

[0036] (2) Alkali treatment: Pour 300mL, 25wt% ammonia water, 300mL, 30wt% hydrogen peroxide and 1500mL water into the acid-treated closed-cell foam ceramic ball, heat the mixed solution to 75°C, and use ultrasonic vibration with 150 rpm Stir for 60 minutes at a rotating speed of 10 minutes, then filter and dry the closed-cell foam c...

Embodiment 3

[0041] A kind of foam fire extinguishing material that contains closed-cell foam ceramic balls, its component comprises in parts by weight: 150g fluoroprotein foam fire extinguishing agent, 125g closed-cell foam ceramic balls and 1000g water.

[0042] The preparation method of the above-mentioned foam fire extinguishing material containing closed-cell foam ceramic balls, the steps are as follows:

[0043] (1) Acid treatment: pour 1250mL concentrated sulfuric acid and 500mL, 30wt% hydrogen peroxide into 300g closed-cell foam ceramic balls, and stir the mixture for 25min at a speed of 120 rpm, rinse the closed-cell foam ceramic balls with water, and dry ;

[0044] (2) Alkali treatment: Pour 250mL, 25wt% ammonia water, 250mL, 30wt% hydrogen peroxide and 1250mL water into the acid-treated closed-cell foam ceramic ball, heat the mixed solution to 70°C, use ultrasonic vibration and cooperate with 100-150 Stir at a speed of rev / min for 55min, then filter and dry the closed-cell foam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com