A mixer for the preparation of toughened and reinforced polyvinyl chloride composite materials

A technology of polyvinyl chloride and composite materials, applied in the field of composite materials, can solve problems such as pollution caused by the environment, and achieve the effects of not easy to pollute, easy to grind, and to prevent floating dust from overflowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

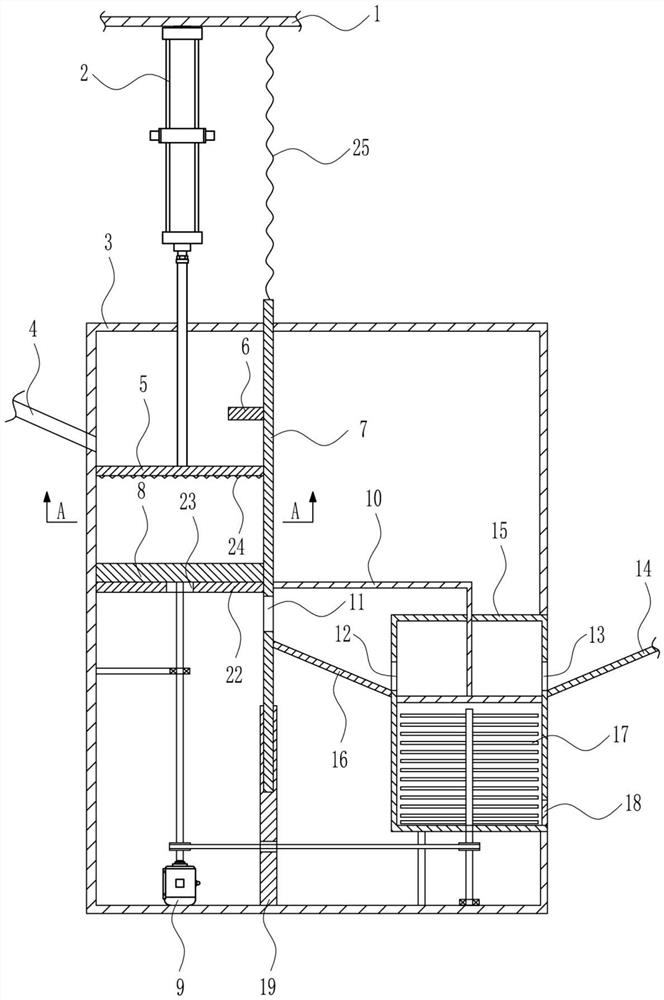

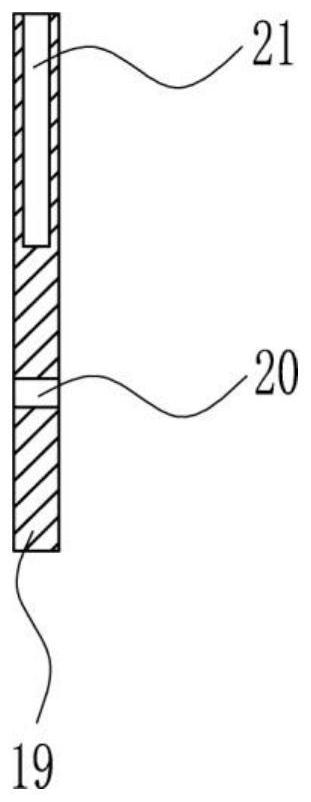

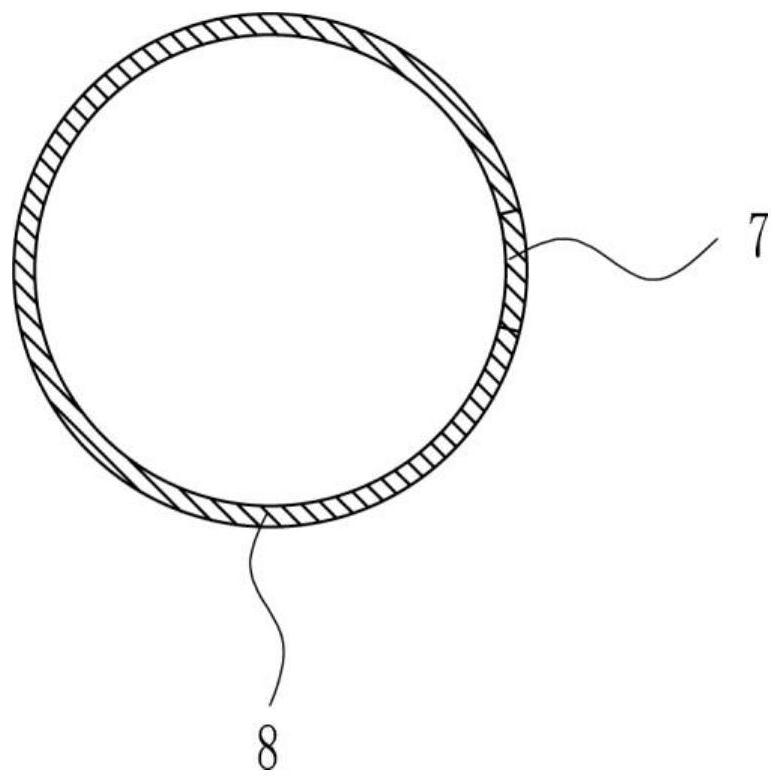

[0028] A mixer for the preparation of toughened and reinforced polyvinyl chloride composite materials, such as Figure 1-6 As shown, it includes a frame 1, a cylinder 2, a tank body 3, a feed pipe 4, a pressure plate 5, a block 6, a partition 7, a grinding disc 8, a crushing power mechanism 9, a closing mechanism 10, and a first material guide plate 14 , the mixing box 15, the second material guide plate 16, the uniform mixing mechanism 17, the gate 18, the positioning plate 19 and the mounting plate 22; the upper part of the left side wall of the tank body 3 is equipped with a feed pipe 4, and the left side of the tank body 3 is fixedly connected There is a mounting plate 22, the middle part of the mounting plate 22 is provided with a third through hole 23 along the vertical direction, the top of the mounting plate 22 is slidingly connected with a grinding disc 8; , the crushing power mechanism 9 is located on the left side of the positioning plate 19, and the power output en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com