A kind of polymer coating diaphragm and preparation method thereof

A polymer coating, polymer technology, applied in the direction of structural parts, electrical components, battery pack components, etc., can solve the problem of insignificant improvement in heat resistance, unfavorable rapid mass production, poor stability of oil-based slurry, etc. problem, to achieve the effect of not easy to fall off, improve ion permeability, and improve safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

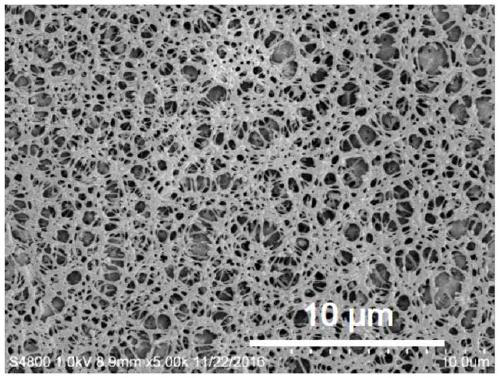

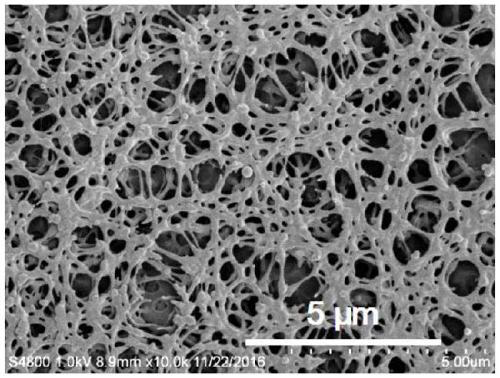

[0036] A polymer coated separator prepared by the following method

[0037] (1) 10g weight average molecular weight Mw is 1.2×10 5 , polyetherimide with molecular weight distribution Mw / Mn of 2 and 1.6g polyvinylidene fluoride were added to 55g N,N-dimethylacetamide and 6.5g ionic liquid [BMIM]BF 4 In the mixed solvent of composition, stir and dissolve at 80 ℃. After the dissolution is complete, add 1.3g polyethylene glycol and 0.6g Tween 80, continue heating and stirring until completely dissolved, then cool and stand for 1 hour.

[0038] (2) Coat both sides of the polyethylene microporous membrane with the prepared coating solution, and place it in a constant temperature and humidity chamber with a temperature of 60°C and a humidity of 80% for 5 minutes to form pores by using the respiration pattern method, and then use deionization Wash with water, and finally dry the diaphragm in hot air at 75°C to obtain a composite diaphragm.

Embodiment 2

[0042] A polymer coated separator prepared by the following method

[0043] (1) The 10g weight average molecular weight Mw is 8×10 4 , polyacrylonitrile with a molecular weight distribution of Mw / Mn of 4 and 2g of vinylidene fluoride-hexafluoropropylene copolymer were added to 40g of N,N-dimethylformamide and 4.5g of ionic liquid [EMIM]AlCl 4 In the mixed solvent of composition, stir and dissolve at 70 ℃. After the dissolution is complete, add 1.5g polyvinylpyrrolidone and 0.4g Tween 60, continue heating and stirring until completely dissolved, then cool and stand for 1.5h.

[0044] (2) Put the prepared coating solution on both sides of the polypropylene microporous membrane after standing for 24 hours, and use the respiration pattern method to make holes, that is, place it in a constant temperature and humidity box with a temperature of 65°C and a humidity of 85%. The pores were formed for 4 minutes, washed with deionized water, and then the membrane was dried in hot air at...

Embodiment 3

[0048] A polymer coated separator prepared by the following method

[0049] (1) The 10g weight average molecular weight Mw is 8×10 4 , molecular weight distribution Mw / Mn is 2 polym-phenylene isophthalamide and 2g polyvinylidene fluoride joins 70g N-methylpyrrolidone and 6.5g ionic liquid [CPMIm]NTf 2 in a mixed solvent, stirred and dissolved at 80°C. After the dissolution is complete, add 1g of polyvinylpyrrolidone and 0.5g of Tween 60, continue heating and stirring until completely dissolved, then cool and stand for 1h.

[0050] (2) Coat the prepared coating solution on both sides of the polyethylene microporous membrane, and use the respiration pattern method to make holes, that is, place it in a constant temperature and humidity box with a temperature of 60 ° C and a humidity of 80% for 5 minutes, and use Wash with deionized water, and finally dry the diaphragm in hot air at 75°C to obtain a composite diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com