Method for continuously preparing UiO series metal framework material through mother liquor dehydration circulation

A metal framework material and mother liquor technology, applied in the field of materials and chemical technology research, can solve the problems of inability to recycle multiple times, affect the reaction rate, and no reports of MOFs synthesis mother liquor, reduce the amount of DMF used, improve economic benefits, The effect of improving atom utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

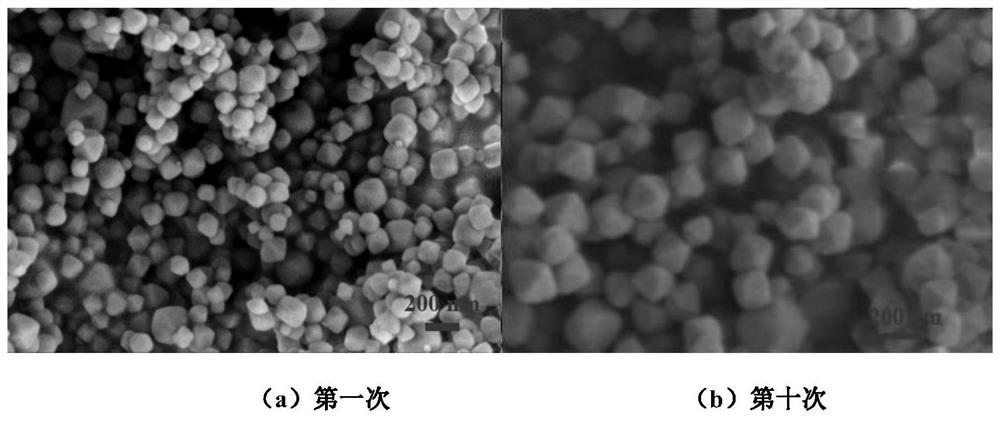

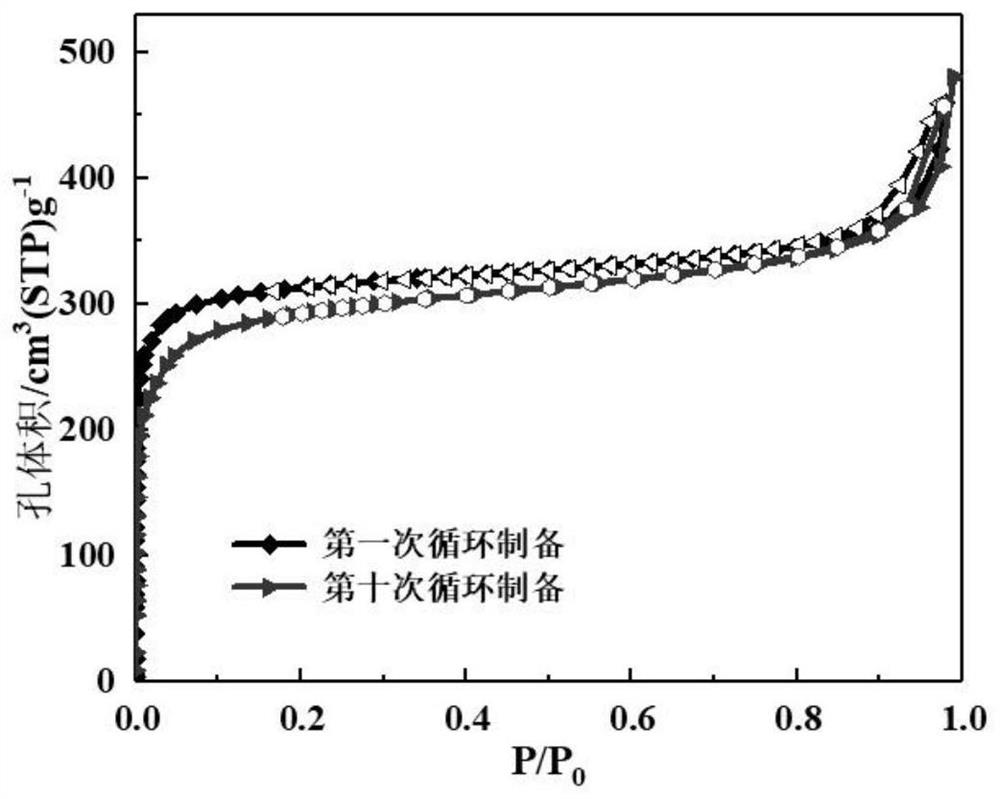

[0028] Mother liquor dehydration and recycling process for synthesizing UiO-66: adopting continuous flow method with ZrOCl ratio as raw material 2 ·8H 2 O:H 2 BDC:HAC:DMF=1:1:100:750 (molar ratio) synthesize UiO-66, collect mother liquor (the water content in mother liquor is 8.46g / L), add acetic anhydride in mother liquor, acetic anhydride and the water in synthetic mother liquor The molar ratio is 2, the mother liquor treatment time is 4h, the mother liquor treatment temperature is 60°C, the water content in the dehydrated mother liquor is 4.11g / L, and ZrOCl is added to the dehydrated mother liquor 2 ·8H 2 O, H 2 BDC and DMF, keep the ratio of reaction raw materials in the mother liquor as ZrOCl 2 ·8H 2 O:H 2 BDC:HAC:DMF=1:1:100:750 (molar ratio), after uniform mixing, use a pump to continuously pass into the coil reactor (700mL) through the T-type mixer, the reaction temperature is 140°C, the residence time is 30min, and the reaction After the end, the UiO-66 solid a...

Embodiment 2

[0034] Synthesis of UiO-66-NH by dehydration and recycling of mother liquor 2 Process: The continuous flow method is adopted, and the reaction raw material ratio is ZrOCl 2 ·8H 2 O:H 2 BDC-NH 2 :HAC:DMF=1:0.9:90:100 (molar ratio) to synthesize UiO-66-NH 2 , Collect the mother liquor (the water content in the mother liquor is 8.79g / L), add acetic anhydride to the mother liquor, the molar ratio of acetic anhydride to water in the synthesis mother liquor is 0.5, the mother liquor treatment time is 1h, the mother liquor treatment temperature is 30°C, and the mother liquor is dehydrated by acetic anhydride After the water content is 3.42g / L, in the mother liquor after dehydration, add ZrOCl 2 ·8H 2 O, H 2 BDC-NH 2 and DMF, keep the reaction raw material ratio in the mother liquor as ZrOCl 2 ·8H 2 O:H 2 BDC-NH 2 :HAC:DMF=1:1:90:100 (molar ratio), after uniform mixing, use a pump to continuously pass into the coil reactor (70mL) through the T-type mixer, the reaction tempe...

Embodiment 3

[0038] Synthesis of UiO-66-(COOH) by Dehydration and Recycle of Mother Liquor 2 Process: The continuous flow method is adopted, and the reaction raw material ratio is ZrOCl 2 ·8H 2 O:H 2 BDC-(COOH) 2 :HAC:DMF=1:1.1:160:350 (molar ratio) to synthesize UiO-66-(COOH) 2 , Collect the mother liquor (the water content in the mother liquor is 8.19g / L), add acetic anhydride to the mother liquor, the molar ratio of acetic anhydride to water in the synthesis mother liquor is 1, the mother liquor treatment time is 2h, the mother liquor treatment temperature is 50°C, and the mother liquor is dehydrated by acetic anhydride After the water content is 4.02g / L, in the mother liquor after dehydration, add ZrOCl 2 ·8H 2 O, H 2 BDC-(COOH) 2 and DMF, keep the reaction raw material ratio in the mother liquor as ZrOCl 2 ·8H 2 O:H 2 BDC-(COOH) 2 :HAC:DMF=1:1:160:350 (molar ratio), after uniform mixing, use a pump to continuously pass into the coil reactor (1000mL) through the T-type mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com