Metal additive for aluminum alloy

A technology of metal additives and aluminum alloys, applied in the direction of material forming presses, coatings, presses, etc., can solve problems such as melting and mixing, inability of additives, crushing and scattering of additives, etc., and achieve the goal of improving rapid dispersion and dissolution and improving the effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

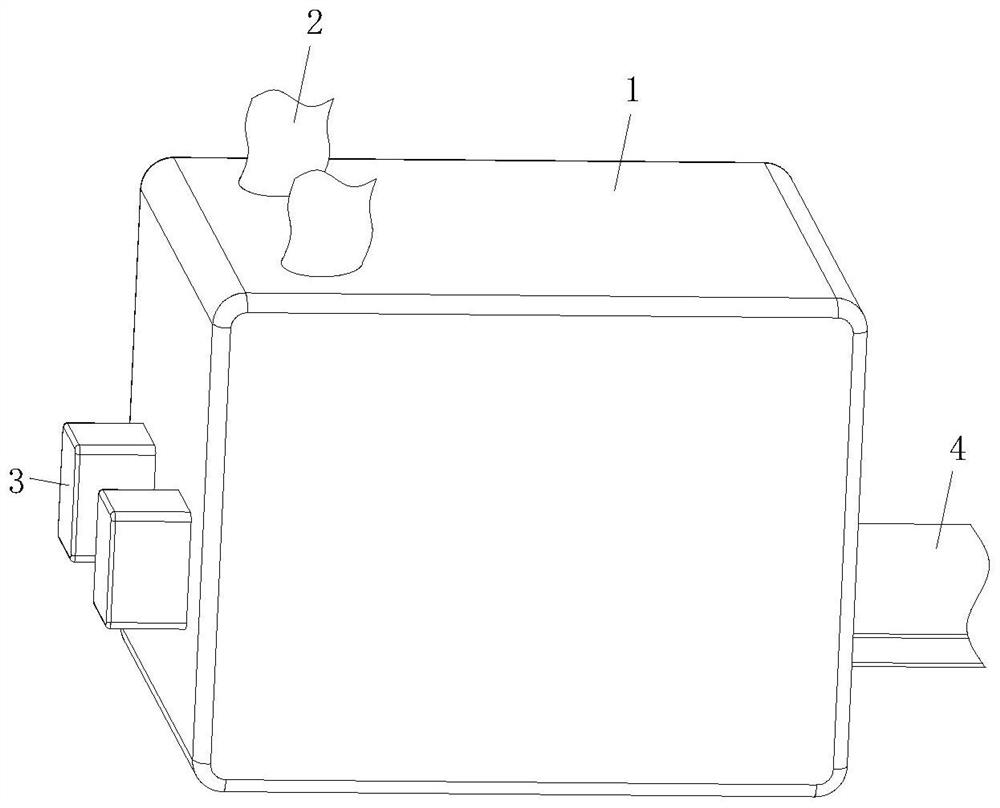

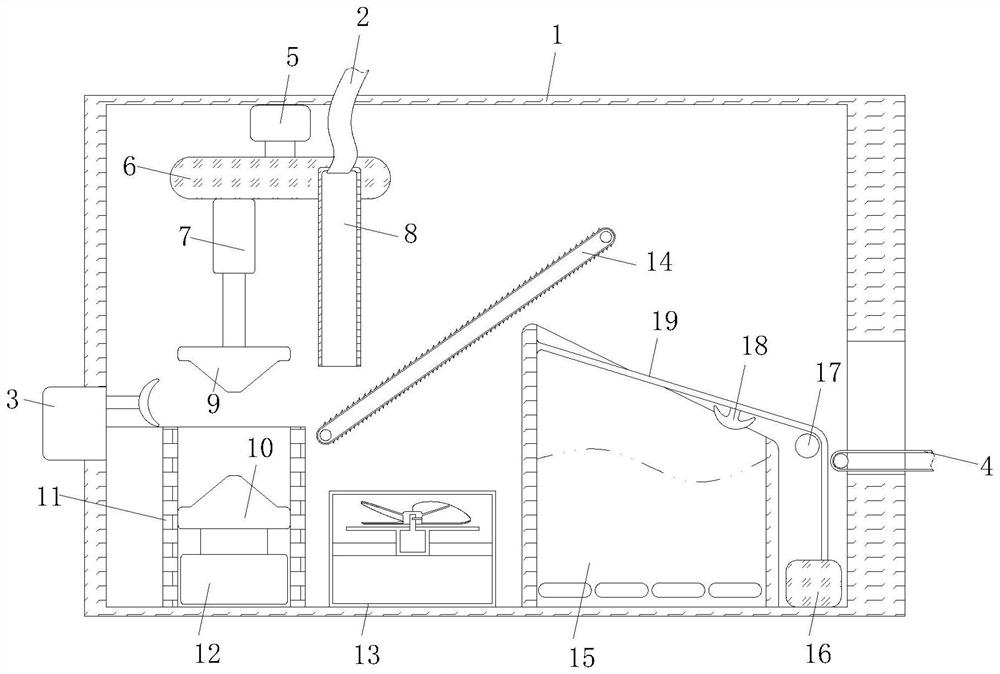

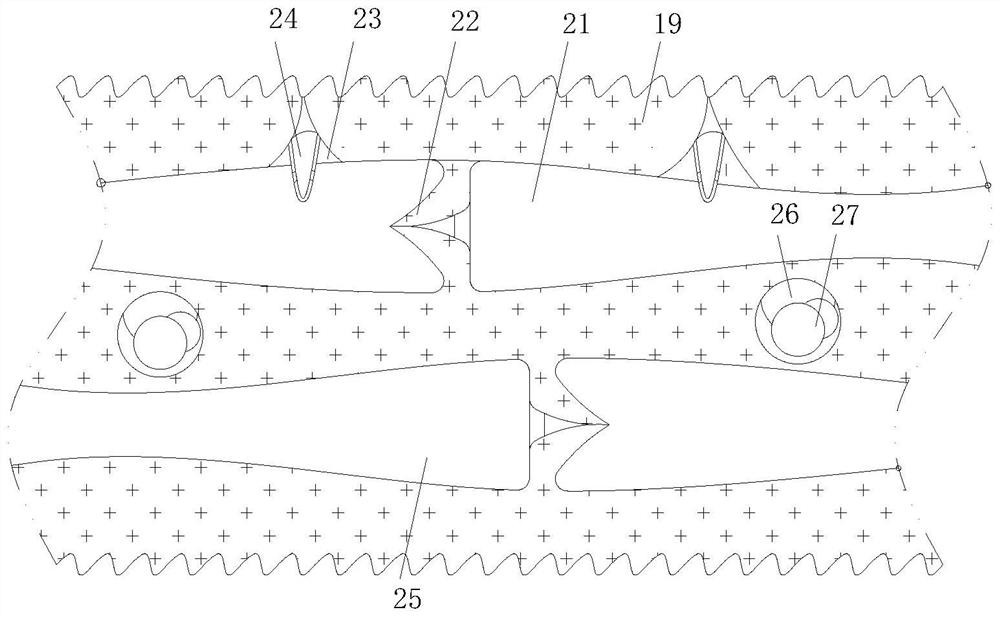

[0035] Such as Figure 1 to Figure 4 As shown, the metal additive for aluminum alloy described in the embodiment of the present invention is characterized in that: the additive is produced by a production device, and the specific composition of the metal additive for aluminum alloy is:

[0037] Stearic acid: 1-5

[0038] Potassium salt: 1-3

[0039] Epoxy: 1-10

[0040] The metal powder is one or more of titanium, copper, manganese and iron;

[0041] Metal additives are prepared by mixing metal powder, stearic acid and potassium salt, and then extruding them into blocks. When producing aluminum alloys, metal additives need to be put into it to adjust the composition of aluminum alloys. , and extruded in a block shape can be convenient for transportation and delivery, but if the extrusion is too full, it is easy to cause the additives to fail to melt and mix quickly during the dissolution process, resulting in poor production effect, but if the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com