Color 3D printing device

A 3D printing and color technology, applied in the direction of manufacturing auxiliary devices, 3D object support structures, manufacturing tools, etc., can solve the problems of low efficiency, connection accuracy, and the inability to present multiple colors at the same time for an object, and achieve controllable color accuracy , Simple structure, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

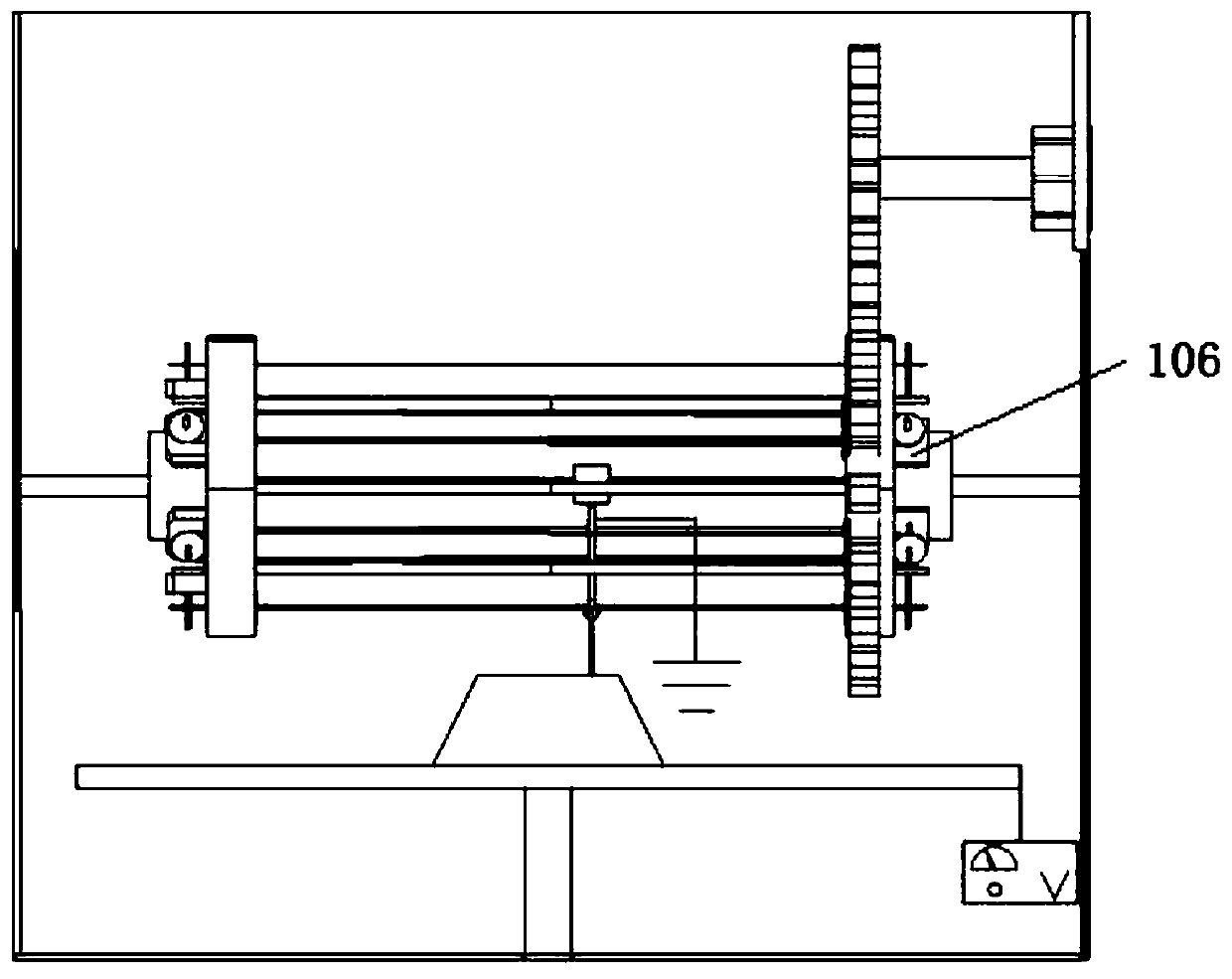

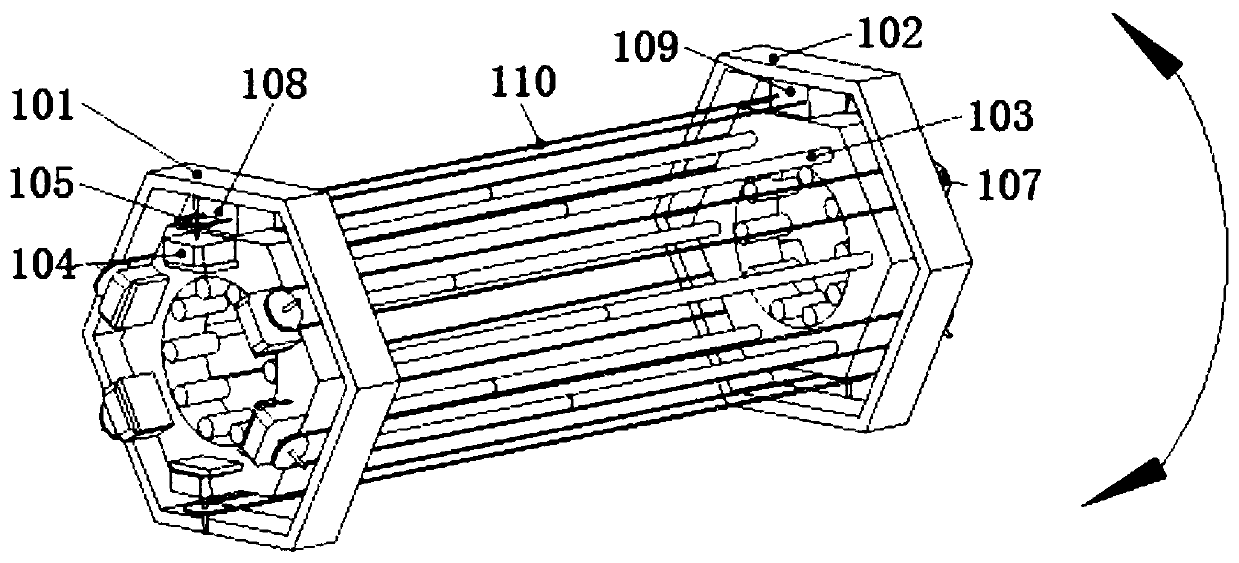

[0029] The main structure of the color 3D printing device involved in this embodiment includes an outer shell 1, a slide rail 2, a lifting slider 3, a conductive receiving plate 4, a high-voltage electrostatic generator 5, a servo motor 6, a driving gear 7, a fixed shaft 8, and a bearing 9. Toning rotating cage 10, driven gear 11 and thimble assembly 12; the outer shell 1 is enclosed by an upper wall, a lower wall, a left wall, a right wall, a front door and a rear wall, and the lower wall A slide rail 2 is arranged on the upper surface of the slide rail 2, and a lifting slider 3 is arranged in the slide rail 2. The top surface of the lifting slider 3 is plugged in with the conductive receiving plate 4, and the conductive receiving plate 4 is electrically connected with the high-voltage electrostatic generator 5. , the right wall plate is provided with a servo motor 6, the servo motor 6 is coaxially plugged in with the driving gear 7, a fixed shaft 8 is arranged between the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com