On-demand micro liquid drop generation method based on pneumatic and electrohydrodynamic hybrid driving

A technology of hybrid drive and production method, which is applied to the parts of color TV, parts of TV system, TV, etc., and can solve the problems of difficulty in realizing on-demand injection, increasing system cost, and inability to realize on-demand injection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

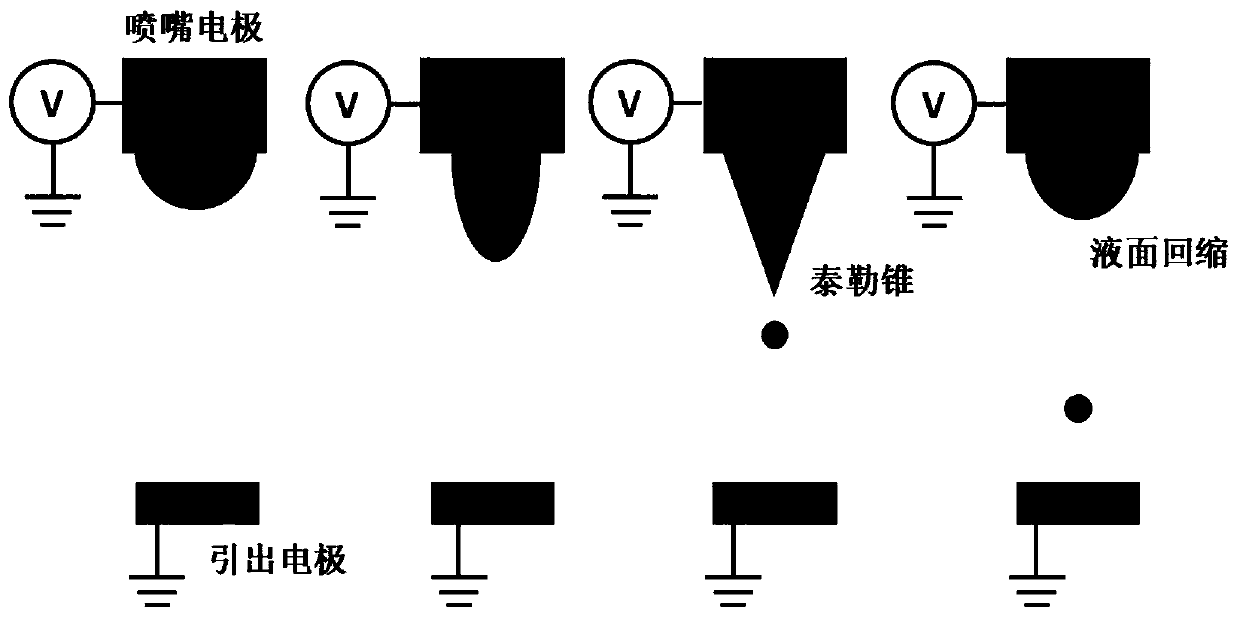

Method used

Image

Examples

Embodiment Construction

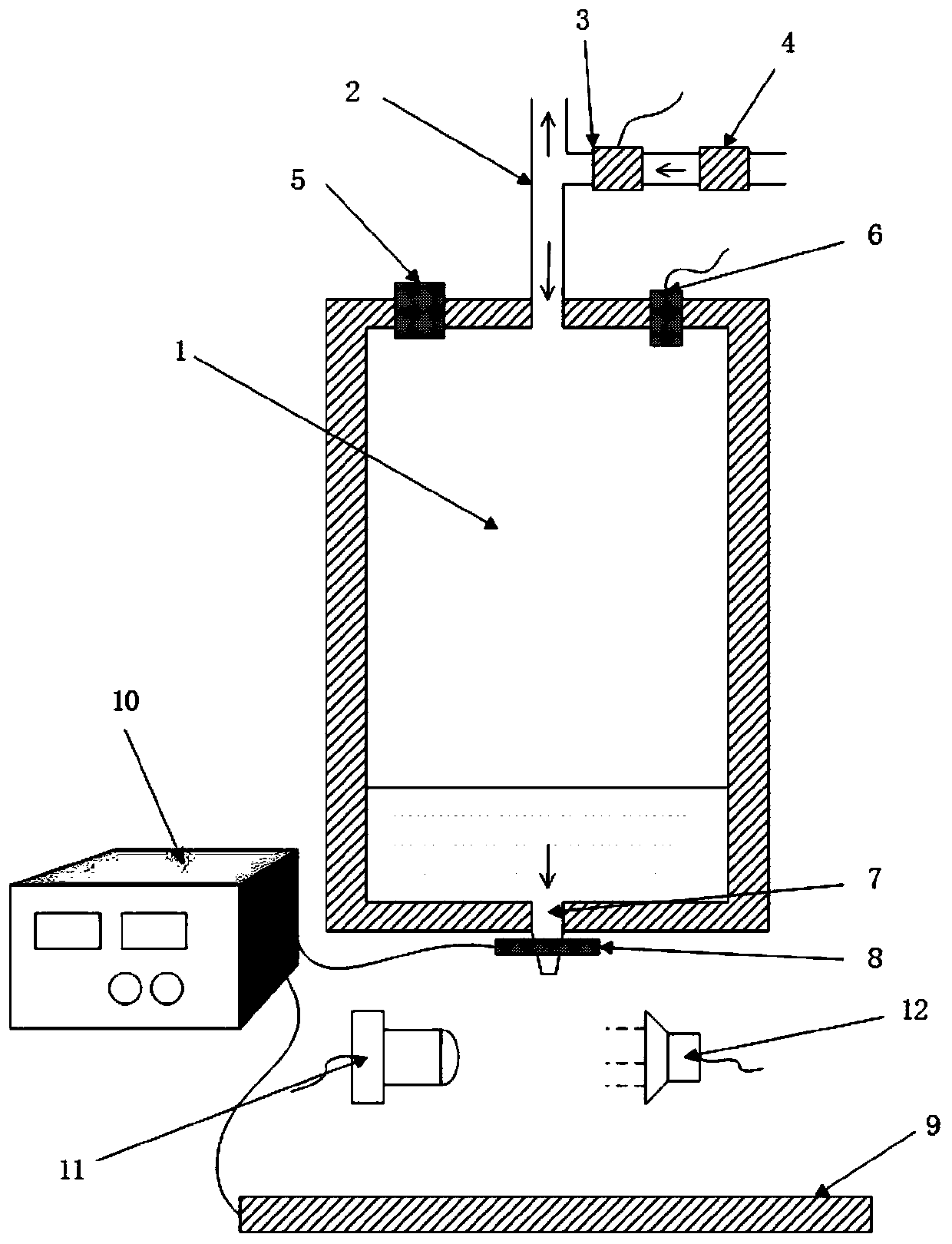

[0013] The device consists of liquid storage chamber 1, air inlet and outlet pipes 2, high-speed solenoid valve 3, pressure regulating valve 4, liquid filling hole 5, air pressure sensor 6, nozzle 7, electrode 8, lead-out electrode 9, high voltage stabilized power supply 10, industrial camera 11 and LED lamp 12 forms. The liquid storage chamber 1 is used to store liquid, the high-speed solenoid valve 3 is used to control the opening and closing of high-pressure gas, the pressure regulating valve 4 adjusts the intake pressure, and the air pressure sensor 6 monitors the pressure in the liquid storage chamber 1. The high voltage stabilized power supply 10 provides high voltage for the EHD system. The LED lamp 12 provides a light source for the industrial camera 11 . The liquid filling hole 5 is used to inject liquid into the liquid storage cavity 1 .

[0014] The specific implementation steps of generating micro-droplets and adjusting the size are as follows:

[0015] S1: Use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com