Wall type fresh air conditioning unit

A fresh air treatment unit and fresh air technology, applied in the heating mode, ventilation system, space heating and ventilation, etc., can solve the problem of insufficient heat exchange of heat exchangers, unconstrained orifice plate air supply airflow, and loud noise at the fresh air inlet, etc. To achieve the effect of saving system energy consumption, reducing noise pollution and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

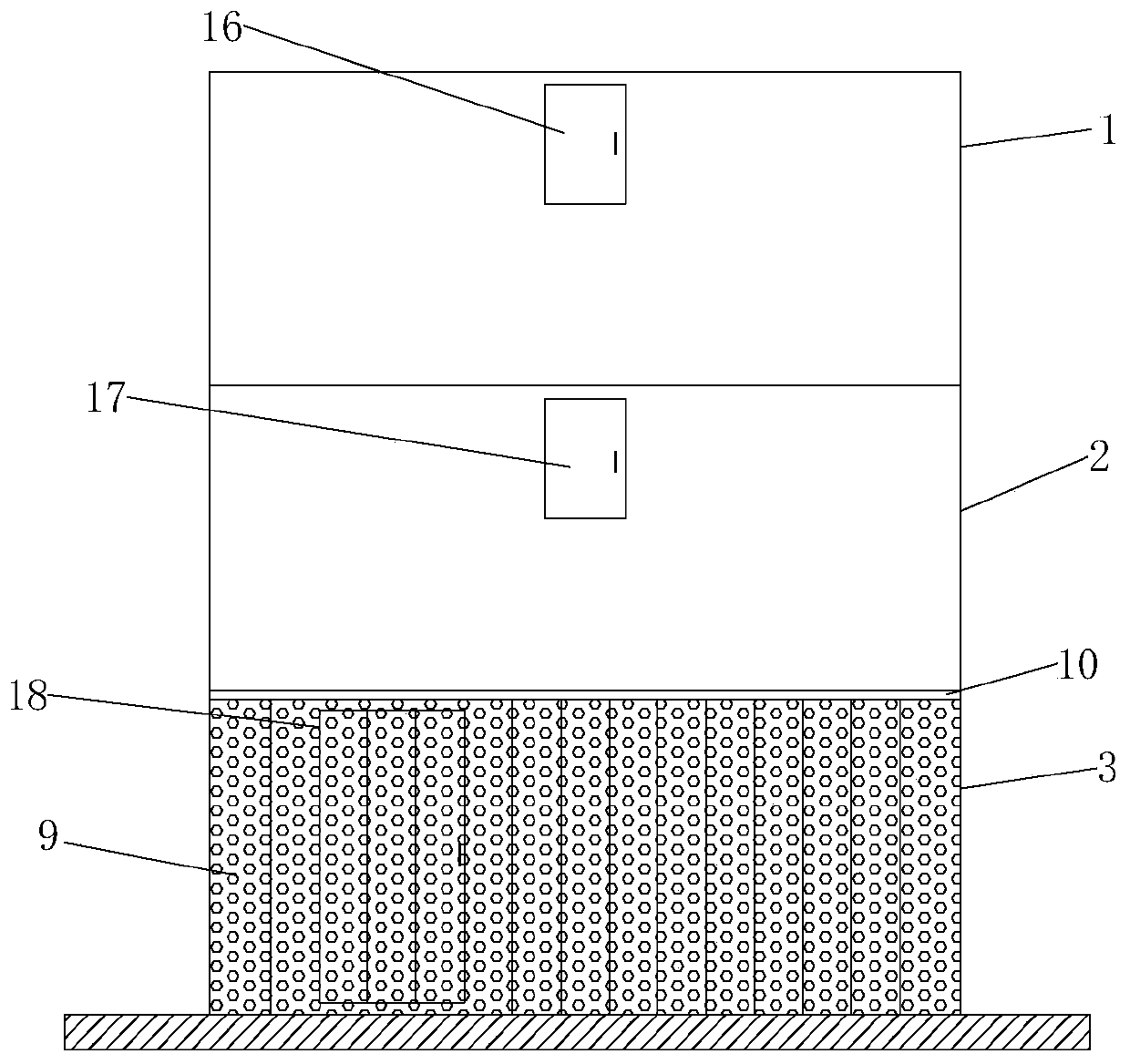

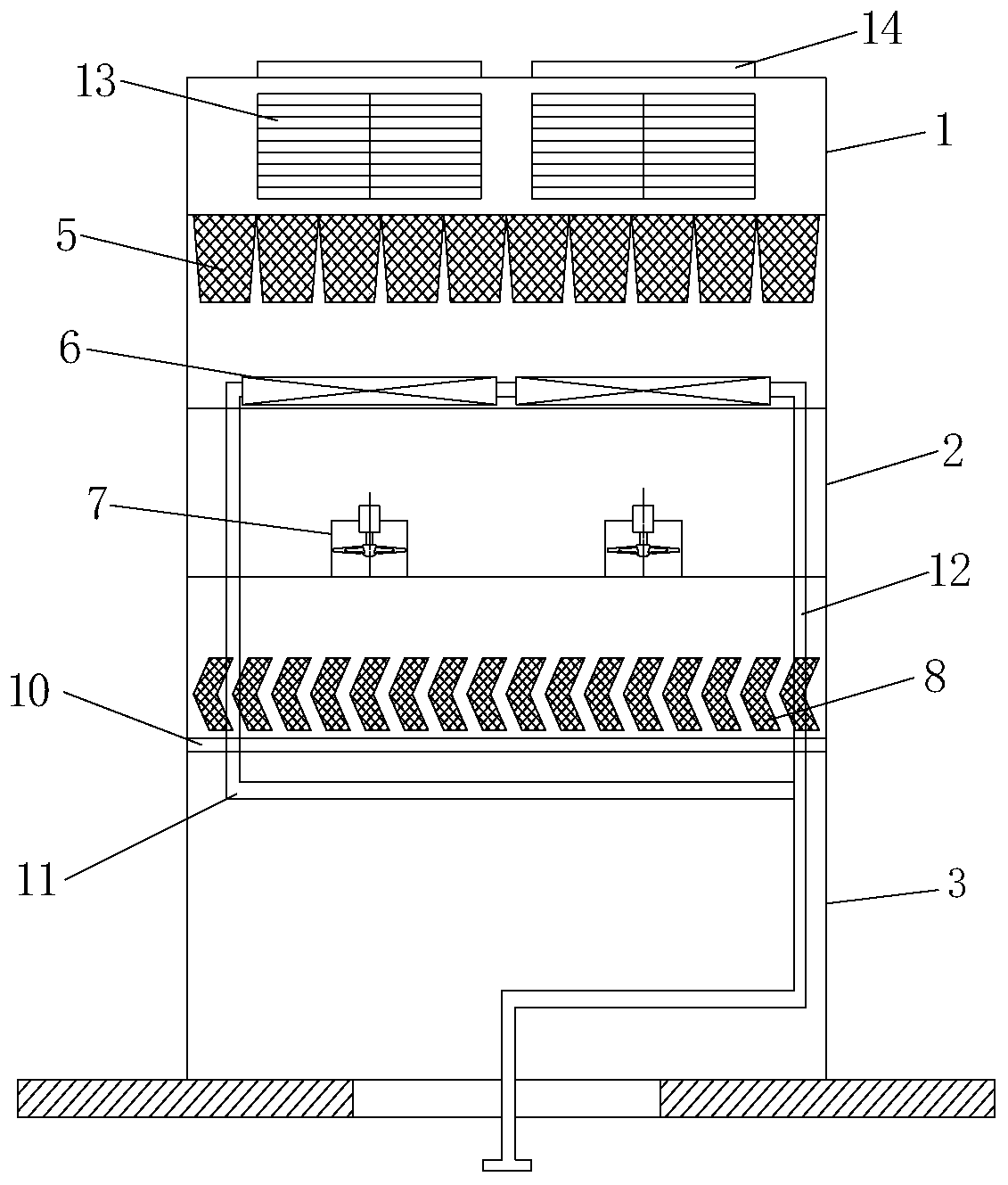

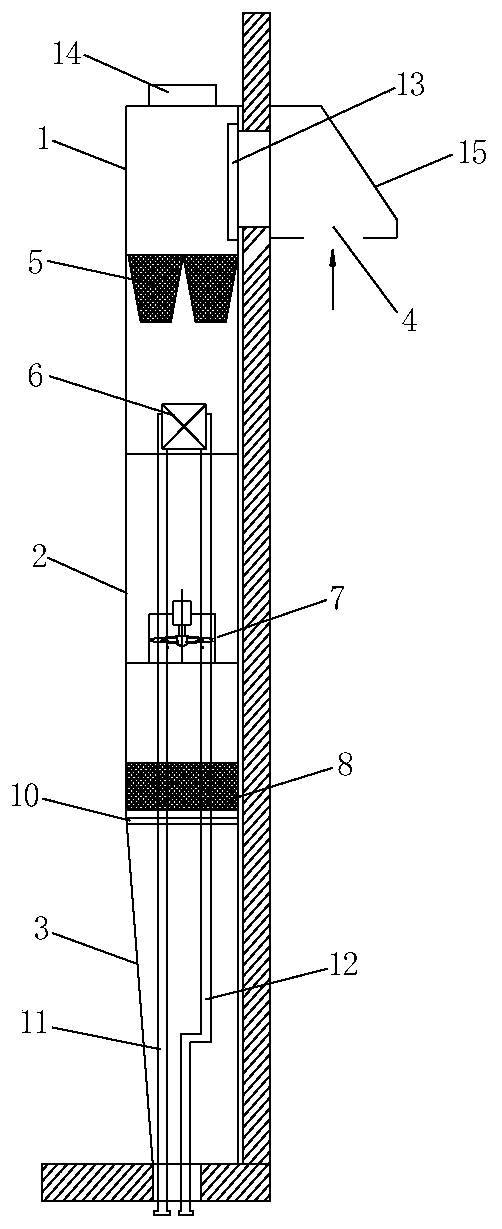

[0050] In this embodiment, the device includes an upper box body 1, a lower box body 2, and an air chamber 3. A fresh air inlet 4 is opened on the back cavity wall of the upper chamber of the upper box body 1 to allow the outside air to enter. The air volume regulating valve 13 is set at the air outlet 4, and a protective cover 15 is equipped in front of the fresh air inlet 4. The interlayer 20 between the inner wall 21 and the outer wall 19 of the protective cover 15 is filled with sound-absorbing materials. The protective cover 15 contains an anti-bird net 22, and the upper box The upper part of the body 1 is provided with a return air system 14, the middle part of the upper box body 1 is provided with an initial effect filter 5, the lower part of the upper box body 1 is provided with a heat exchanger 6 for heating air, and the water inlet pipe 11 and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com