Integrated substrate gap waveguide feed slot coupling metasurface antenna

An integrated substrate and waveguide feeding technology, applied in antennas, antenna couplings, antenna components, etc., can solve problems such as leakage, narrow bandwidth of millimeter-wave antennas, and low gain, and achieve the goal of increasing gain, increasing bandwidth, and reducing thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

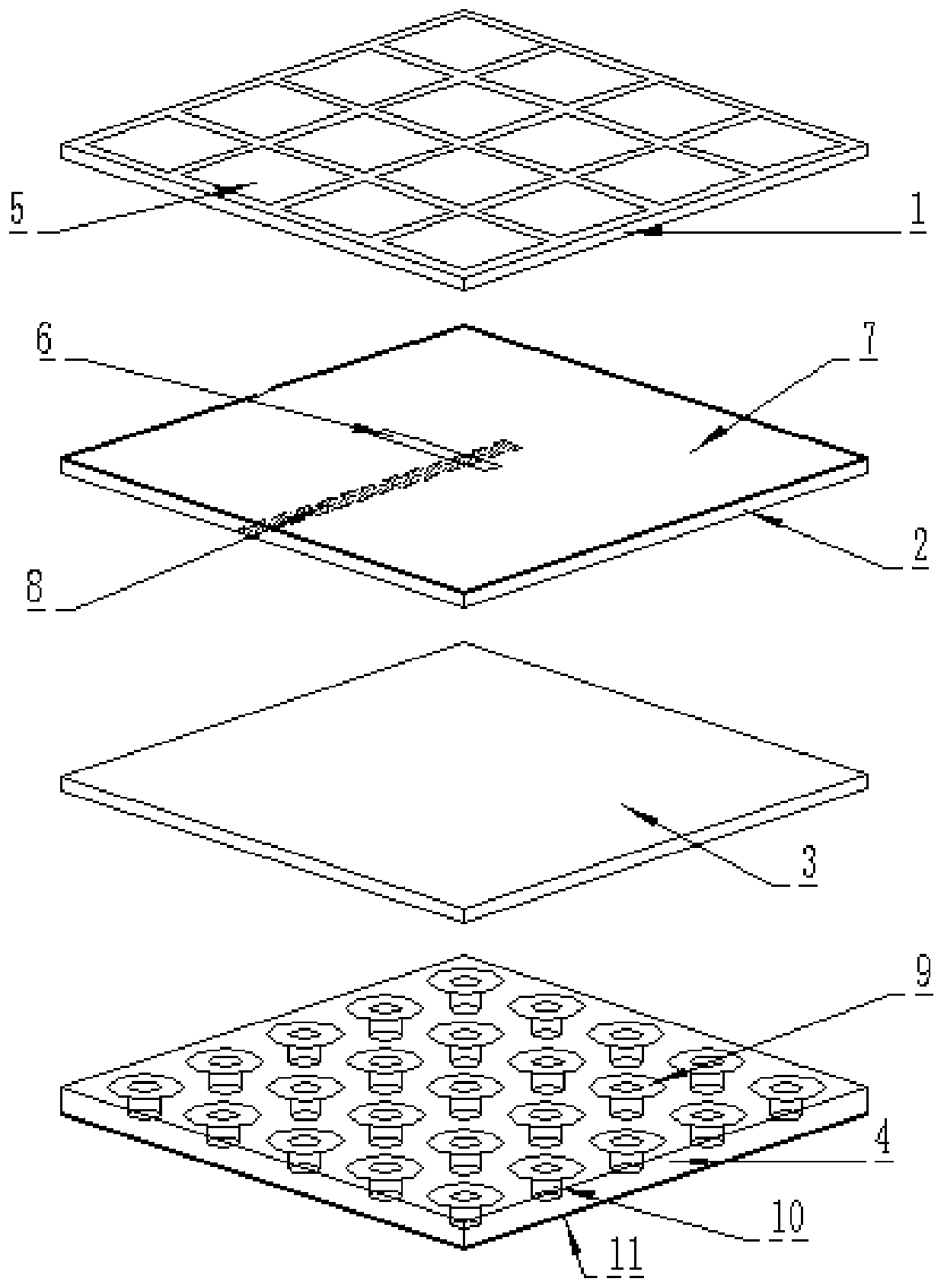

[0045] Such as figure 1 As shown, the present invention includes a first medium plate 1, a second medium plate 2, a third medium plate 3, and a fourth medium plate 4; the first medium plate 1, the second medium plate 2, the third medium plate 3, The fourth dielectric board 4 is pressed together to form a whole. ISGW substrate integrated gap waveguide.

[0046] The upper surface of the first dielectric board 1 has periodically arranged corner-cut patches 5 as a radiation structure, and the upper surface of the second dielectric board 2 has a first copper clad layer 7 as an antenna ground.

[0047] The integrated substrate gap waveguide structure is composed of a second dielectric board 2, a third dielectric board 3 and a fourth dielectric board 4; the upper surface of the second dielectric board 2 has a first copper clad layer 7, and the lower surface of the second dielectric board 2 is printed with With a feeder 8; a rectangular slit 6 is etched on the first copper clad laye...

Embodiment 2

[0058] Such as Figure 4 As shown, on the basis of Embodiment 1, the square patches 5 are replaced with corner-cut patches 12 .

[0059] Among them, the first dielectric plate 1, the second dielectric plate 2, and the third dielectric plate 3 are made of materials with a dielectric constant of 2.2 and a loss tangent of 0.0009; the fourth dielectric plate 4 is made of a material with a dielectric constant of 4.4 and a loss tangent of 0.0009. Made from a material with a tangent of 0.02. The overall size of the antenna is 12mm*12mm*1.362mm.

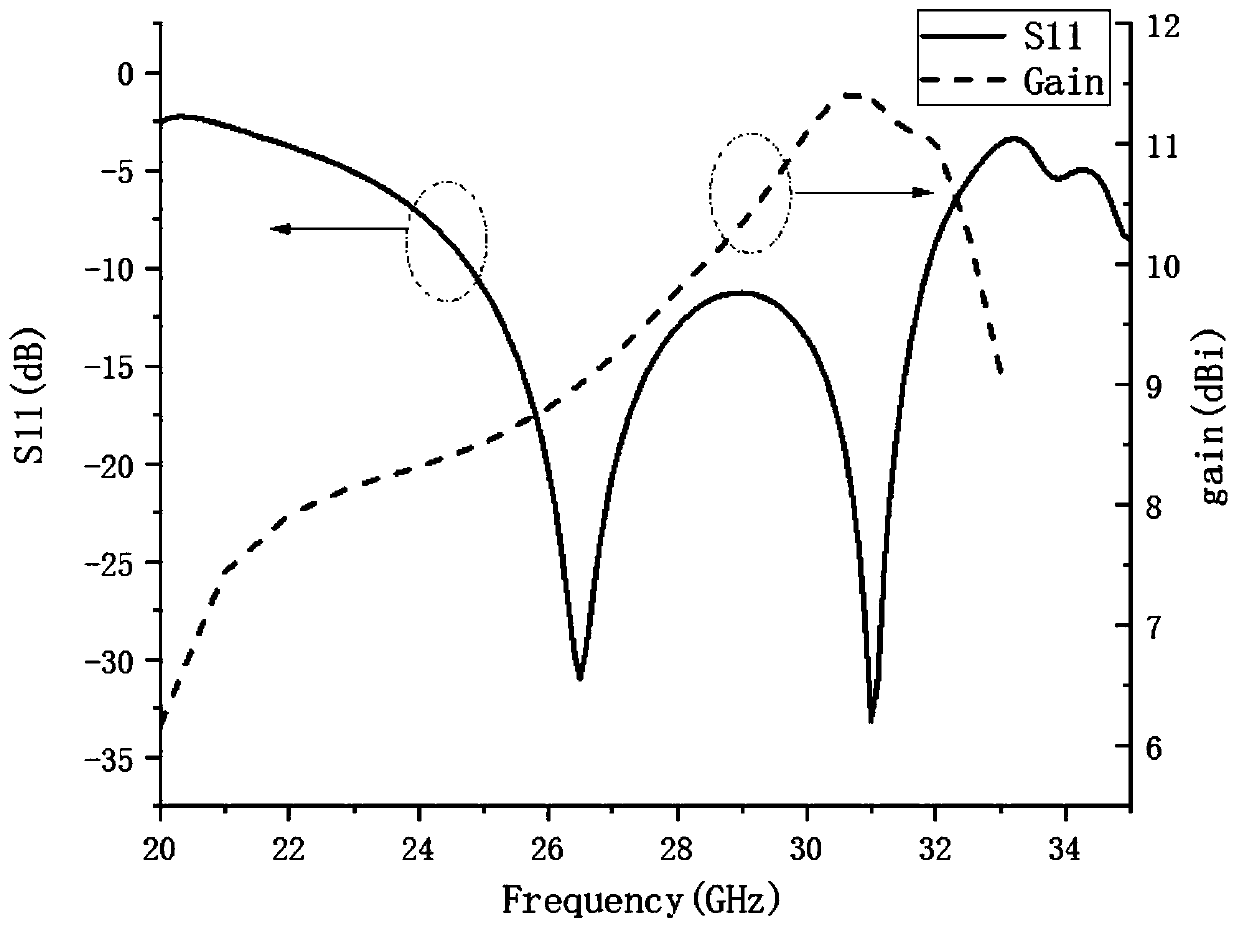

[0060] attached Figure 5 The shown return loss, gain and axial ratio simulation results show that a kind of ISGW feeding slot coupling metasurface circularly polarized antenna of the present invention has a center frequency of 28.08GHz, a -10dB impedance bandwidth of 25.34GHz-30.81GHz, and an absolute bandwidth of 5.47GHz , the relative bandwidth is 19.5%, the 3dB axial ratio bandwidth is 28.15GHz-32.28GHz, the absolute bandwidth is 4.13...

Embodiment 3

[0063] Such as Figure 7 As shown, the present invention includes a first dielectric board 1, a second dielectric board 2, and a fourth dielectric board 4; the first dielectric board 1, the second dielectric board 2, and the fourth dielectric board 4 are pressed together to form a overall.

[0064] The upper surface of the first dielectric board 1 has periodically arranged square patches 5 or corner-cut patches 12 as a radiation structure, and the upper surface of the second dielectric board 2 has a first copper clad layer 7 as an antenna ground.

[0065] The integrated substrate gap waveguide structure is composed of a second dielectric board 2 and a fourth dielectric board 4; the upper surface of the second dielectric board 2 has a first copper clad layer 7, and the lower surface of the second dielectric board 2 is printed with a microstrip feeder 8; the first Rectangular slits 6 are etched on the copper clad layer 7 ; metal via holes 10 arranged periodically are opened on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com