Preparation method of high-protein yoghurt

A high-protein, high-protein technology, applied in the field of high-protein yogurt preparation, can solve problems such as poor sensory quality, and achieve the effect of improving the overall sensory quality, improving the taste, and rich and thick creamy feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

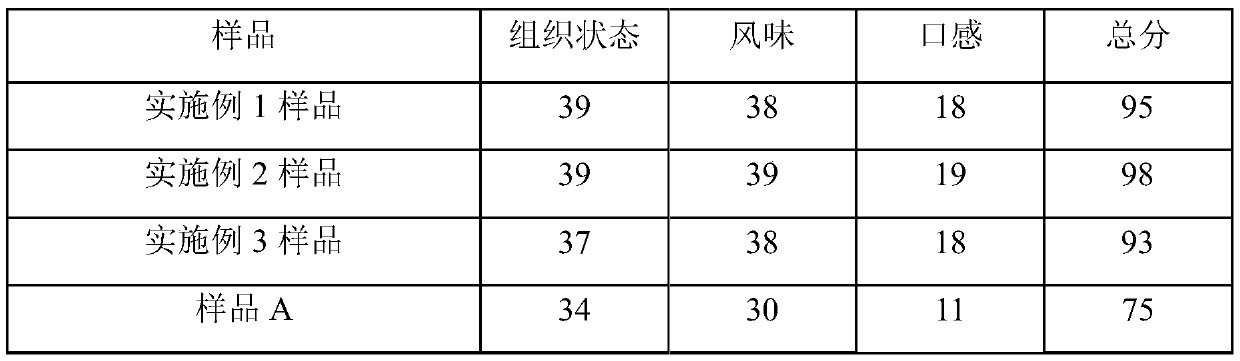

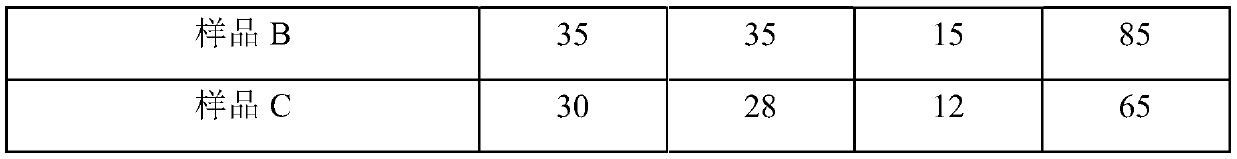

Embodiment 1

[0044] A high-protein yoghurt comprising the following components in mass percentage: 89% of raw milk, 2.0% of concentrated whey protein powder A, 0.5% of concentrated whey protein powder B, 1.5% of concentrated milk protein powder, and 7% of white sugar ; The high-protein yoghurt also includes a starter, and the amount of the starter is 0.15U / kg.

[0045] Wherein, the starter is a composite bacterial agent of Lactobacillus acidophilus, Lactobacillus delbrueckii subsp. bulgaricus and Bifidobacterium bifidum, and the effective number of viable bacteria is 10 9 ~10 10 cfu / U.

[0046] The preparation method of this high-protein yoghurt comprises the following steps:

[0047] S1. Mixing: Put the raw milk into the mixing tank (with a high-speed shear head at the bottom of the tank), raise the temperature to 55°C, and slowly add the above protein composition in proportion while stirring at 500r / min. Stir for more than 30 minutes to hydrate the protein powder; when the sedimentati...

Embodiment 2

[0052] A high-protein yoghurt comprising the following components in mass percent: 88% raw milk, 2.2% concentrated whey protein powder A, 1.0% concentrated whey protein powder B, 1.8% concentrated milk protein powder, and 7% white sugar ; The high-protein yogurt also includes a starter, and the amount of the starter is 0.2U / kg.

[0053] Wherein, the starter is a composite bacterial agent of Bifidobacterium lactis, Lactobacillus helveticus and Lactobacillus rhamnosus, and the effective number of viable bacteria is 10 9 ~10 10 cfu / U.

[0054] The preparation method of this high-protein yoghurt comprises the following steps:

[0055] S1. Mixing: Put the raw milk into the mixing tank (with a high-speed shear head at the bottom of the tank), raise the temperature to 57°C, and slowly add the above protein composition in proportion while stirring at 700r / min. Stir for more than 30 minutes to hydrate the protein powder; when the sedimentation rate index of the mixed solution is <0....

Embodiment 3

[0060] A high-protein yogurt, comprising the following components in mass percentage: 87.3% of raw milk, 2.5% of concentrated whey protein powder A, 1.2% of concentrated whey protein powder B, 2.0% of concentrated milk protein powder, and 7% of white sugar; The high-protein yoghurt also includes a starter, and the amount of the starter is 0.18U / kg.

[0061] Wherein, the leavening agent is a compound microbial agent of Lactobacillus casei and Streptococcus thermophilus, and the effective number of viable bacteria is 10 9 ~10 10 cfu / U.

[0062] The preparation method of this high-protein yoghurt comprises the following steps:

[0063] S1. Mixing: Put the raw milk into the mixing tank (with a high-speed shear head at the bottom of the tank), raise the temperature to 60°C, and slowly add the above protein composition in proportion while stirring at 800r / min. Stir for more than 30 minutes to hydrate the protein powder; when the sedimentation rate index of the mixed solution is <...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com