High-chlorophyll-content bamboo salt and preparation method thereof

A technology of chlorophyll and bamboo salt, which is applied in ultrasonic treatment of food, function of food ingredients, food ingredients containing natural extracts, etc., can solve the problems of mixed particles, large raw materials, and high energy consumption, and achieves good color rendering. , The effect of increasing dissolution and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

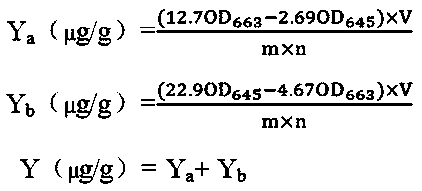

Image

Examples

Embodiment 1

[0029] A preparation method of high chlorophyll bamboo salt, comprising the following steps:

[0030] (1) Raw material pretreatment: select 10kg of fresh bamboo leaves to wash, drain and dry at 40°C for 3 hours, then crush them through a 20-mesh sieve to obtain bamboo leaf powder for later use;

[0031] (2) Preparation of bamboo leaf extract: mix bamboo leaf powder with 100kg of 95% edible alcohol, then perform ultrasonic treatment at 45°C, power 175w, time 52min, filter to obtain bamboo leaf extract for later use;

[0032] (3) Bamboo salt preparation: mix 20kg of refined salt with bamboo leaf extract, and then perform ultrasonic treatment at 45°C with a power of 125w and a time of 35min to obtain a mixture of bamboo salt for later use;

[0033] (4) Drying and crushing: filter the bamboo salt mixture, take the filter residue and dry it with hot air, arrange, crush and pack after drying, and obtain a kind of bamboo salt with high chlorophyll.

Embodiment 2

[0035] A preparation method of high chlorophyll bamboo salt, comprising the following steps:

[0036] (1) Raw material pretreatment: select 9kg of fresh bamboo leaves, wash them, drain and dry them at 40°C for 2 hours, then crush them through a 20-mesh sieve to obtain bamboo leaf powder for later use;

[0037] (2) Preparation of bamboo leaf extract: mix bamboo leaf powder with 90kg of 95% edible alcohol, then perform ultrasonic treatment at 40°C, power 150w, time 45min, filter to obtain bamboo leaf extract for later use;

[0038] (3) Bamboo salt preparation: mix 18kg of refined salt with bamboo leaf extract, and then perform ultrasonic treatment at 40°C with a power of 100w and a time of 30min to obtain a mixture of bamboo salt for later use;

[0039] (4) Drying and crushing: filter the bamboo salt mixture, take the filter residue and dry it with hot air, arrange, crush and pack after drying, and obtain a kind of bamboo salt with high chlorophyll.

Embodiment 3

[0041] A preparation method of high chlorophyll bamboo salt, comprising the following steps:

[0042] (1) Raw material pretreatment: select 11 kg of fresh bamboo leaves, wash them, drain them and dry them at 40°C for 4 hours, then crush them through a 20-mesh sieve to obtain bamboo leaf powder for later use;

[0043] (2) Preparation of bamboo leaf extract: mix bamboo leaf powder with 110kg of 95% edible alcohol, then perform ultrasonic treatment at 50°C, power 200w, time 60min, filter to obtain bamboo leaf extract for later use;

[0044] (3) Bamboo salt preparation: mix 22kg of refined salt with bamboo leaf extract, and then perform ultrasonic treatment at 50°C with a power of 150w and a time of 40min to obtain a mixture of bamboo salt for later use;

[0045] (4) Drying and crushing: filter the bamboo salt mixture, take the filter residue and dry it with hot air, arrange, crush and pack after drying, and obtain a kind of bamboo salt with high chlorophyll.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com