Test platform for conveying dry powder extinguishing agent

A dry powder fire extinguishing agent and experimental platform technology, applied in conveyors, conveying bulk materials, fire rescue and other directions, can solve the problems of lack of dry powder blowing and conveying test platform, no safe and reliable experimental platform, inhalation injury of experimental personnel, etc. The recycling route is simple, accurate detection is achieved, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0031] The specific embodiments of the present invention are for the convenience of further description of the concept of the present invention, the technical problems to be solved, the technical features constituting the technical solution and the technical effects brought about. It should be noted that the description of these embodiments does not constitute a limitation of the present invention. In addition, the technical features involved in the following embodiments of the present invention may be combined with each other as long as they do not conflict with each other.

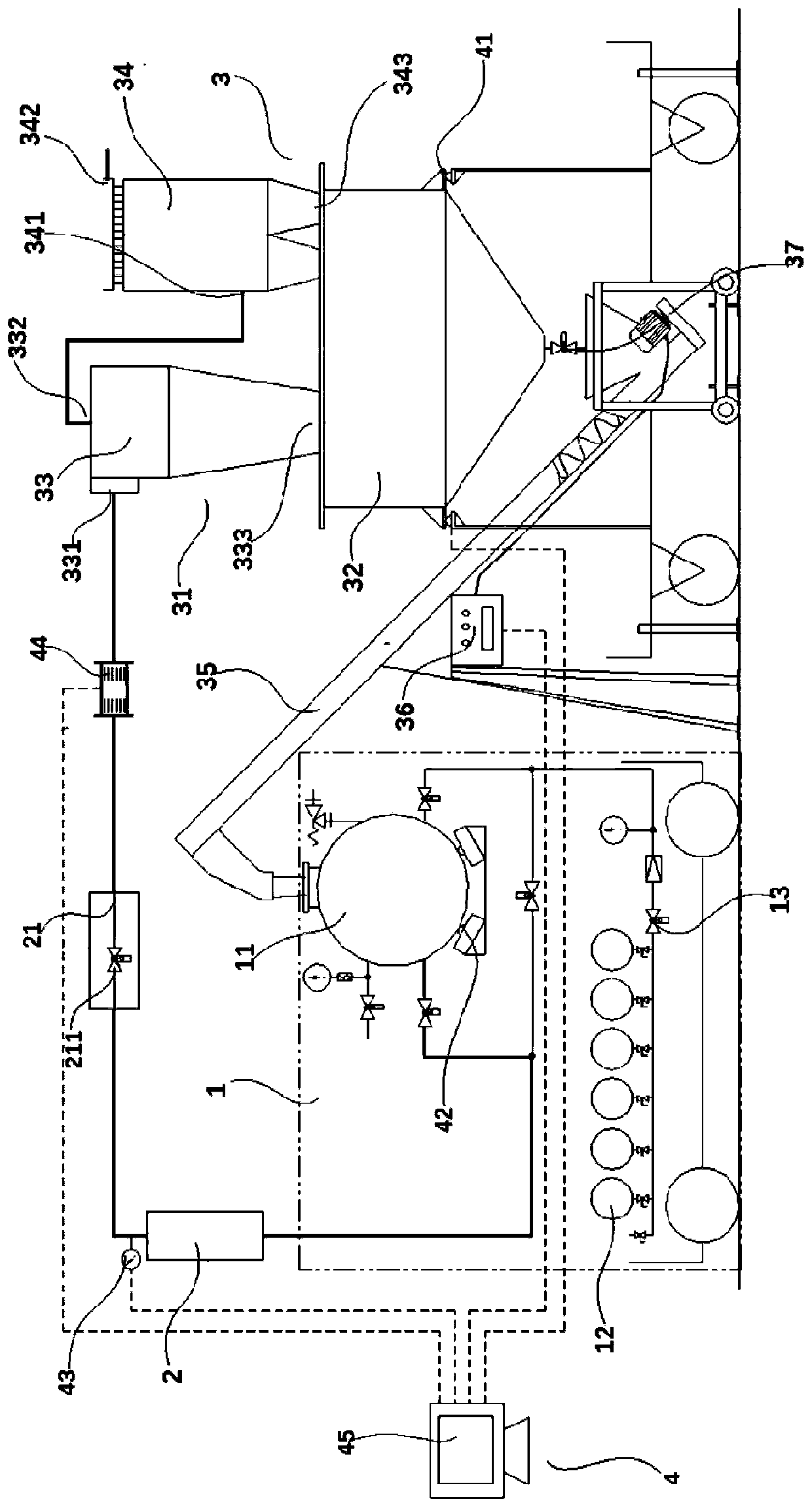

[0032] Such as figure 1As shown, the present invention provides a dry powder fire extinguishing agent delivery experiment platform, comprising: a fluidized blowing device for generating dry powder fire extinguishing agent available for injection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com