Brick firing method by using domestic sludge

A domestic sludge and brick pile technology, applied in the field of brick burning, can solve the problems of complex carbonization equipment, high cost, air pollution, etc., achieve better compressive strength and freeze-thaw resistance, improve heat release efficiency, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

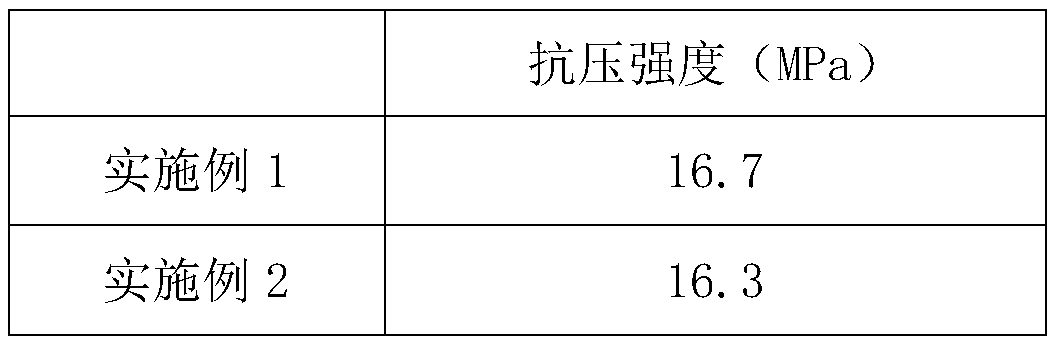

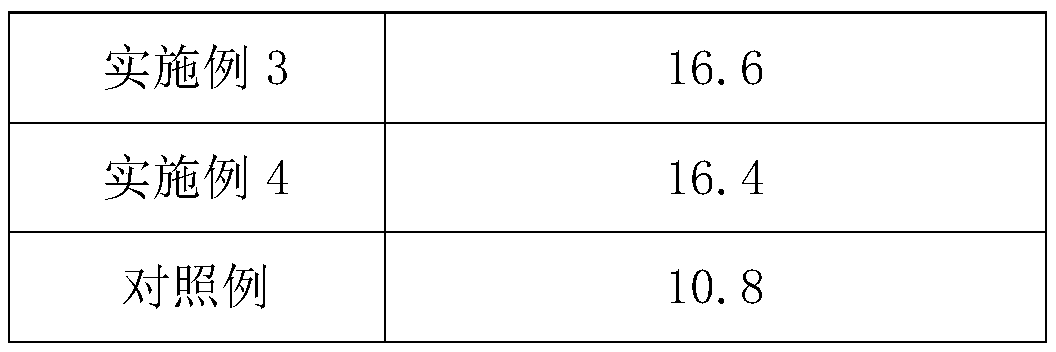

Examples

Embodiment 1

[0019] The brick burning method of domestic sludge comprises the following steps:

[0020] (1) Stack the bricks on the kiln car into a number of brick piles, leave a predetermined space between two adjacent brick piles, and send the kiln car into the high-temperature section of the brick-burning tunnel kiln for sintering;

[0021] (2) drying and pulverizing the domestic sludge into domestic sludge powder with a water content lower than 10% and a particle size of 0.8 mm;

[0022] (3) Install several biomass burners outside the high-temperature section of the brick-burning tunnel kiln at a temperature of 900°C, connect the nozzle pipe of the biomass burner into the brick-burning tunnel kiln, and pass domestic sludge powder through the biomass burner Spray into the predetermined space between two adjacent brick stacks, the domestic sludge powder is atomized and burned to release heat for brick burning, and the formed inorganic ash settles on the kiln car;

[0023] (4) Collect th...

Embodiment 2

[0025] The brick burning method of domestic sludge comprises the following steps:

[0026] (1) Stack the bricks on the kiln car into a number of brick piles, leave a predetermined space between two adjacent brick piles, and send the kiln car into the high-temperature section of the brick-burning tunnel kiln for sintering;

[0027] (2) drying and pulverizing the domestic sludge into domestic sludge powder with a moisture content lower than 10% and a particle size of 0.1 mm;

[0028] (3) Install several biomass burners outside the high-temperature section of the brick-burning tunnel kiln at a temperature of 900°C, connect the nozzle pipe of the biomass burner into the brick-burning tunnel kiln, and pass domestic sludge powder through the biomass burner Spray into the predetermined space between two adjacent brick stacks, the domestic sludge powder is atomized and burned to release heat for brick burning, and the formed inorganic ash settles on the kiln car;

[0029] (4) Collect...

Embodiment 3

[0031] The brick burning method of domestic sludge comprises the following steps:

[0032] (1) Stack the bricks on the kiln car into a number of brick piles, leave a predetermined space between two adjacent brick piles, and send the kiln car into the high-temperature section of the brick-burning tunnel kiln for sintering;

[0033] (2) drying and pulverizing the domestic sludge into domestic sludge powder with a moisture content lower than 10% and a particle size of 1 mm;

[0034] (3) Install a number of biomass burners outside the high-temperature section of the brick-burning tunnel kiln at a temperature of 1000°C, connect the nozzles of the biomass burners into the brick-burning tunnel kiln, and pass domestic sludge powder through the biomass burner Spray into the predetermined space between two adjacent brick stacks, the domestic sludge powder is atomized and burned to release heat for brick burning, and the formed inorganic ash settles on the kiln car;

[0035] (4) Collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com