High-fluffiness down preparation method

The technology of bulkiness and down is applied in the field of preparation of high bulkiness down, which can solve the problems of sensitivity, down fiber damage, and high irritation of aldehyde cross-linking agents, and achieve the effect of improving economic benefits and increasing bulkiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

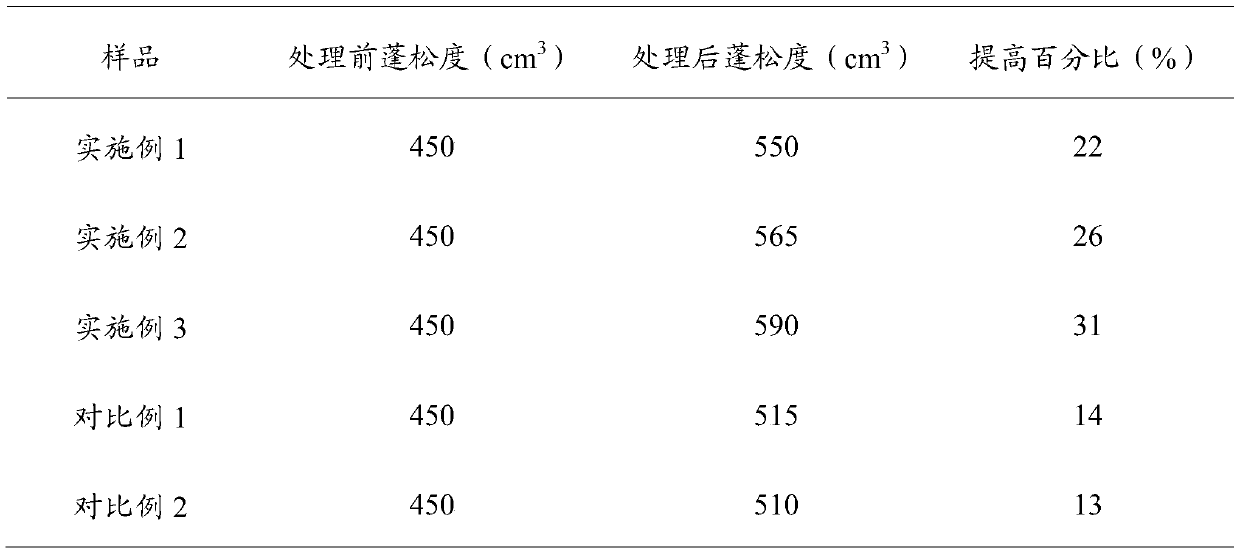

Examples

Embodiment 1

[0021] A preparation method of high bulkiness down, comprising the following steps:

[0022] Add down, water and Liannuo Chemical LQ-5 degreasing agent into the washing machine, the mass ratio of down and water is 1:40, add 2g of LQ-5 degreasing agent per liter of water, the degreasing temperature is 40°C, and the degreasing time is 70min , the degreasing is completed, washed three times with warm water, and drained; put the degreased down into the washing machine, and add papain, the mass ratio of down and water is 1:30, and the dosage ratio of papain to water is 0.1g:1L , the softening temperature is 25°C, and the softening time is 20 minutes; the softened down is added to water, and glutamine transaminase is added, the mass ratio of down and water is 1:30, and the dosage ratio of glutamine transaminase to water is 0.2 : 1L, the crosslinking temperature is 40°C, the crosslinking time is 50min, drained, dried, and ready to be tested.

Embodiment 2

[0024] A preparation method of high bulkiness down, comprising the following steps:

[0025] Add down, water and Liannuo Chemical LQ-5 degreasing agent into the washing machine, the mass ratio of down and water is 1:50, add 1.5g LQ-5 per liter of water, the degreasing temperature is 45°C, and the degreasing time is 65min. Degreasing is completed, washed three times with warm water, drained; put the degreased down into the washing machine, and add papain, the mass ratio of down and water is 1:32, the dosage ratio of papain and water is 0.2g:1L, The softening temperature is 27°C, and the softening time is 25 minutes; the softened down is added to water, and transglutaminase is added. The mass ratio of down and water is 1:33, and the dosage ratio of transglutaminase to water is 0.3: 1L, the crosslinking temperature is 43°C, the crosslinking time is 55min, drained, dried, and ready for testing.

Embodiment 3

[0027] A preparation method of high bulkiness down, comprising the following steps:

[0028] Add down, water and Liannuo Chemical LQ-5 degreasing agent into the washing machine. The mass ratio of down and water is 1:45. Add 1.7g of LQ-5 per liter of water. The degreasing temperature is 42°C and the degreasing time is 60 minutes. Degreasing is completed, washed three times with warm water, drained; put the degreased down into the washing machine, and add papain, the mass ratio of down and water is 1:35, the dosage ratio of papain and water is 0.3g:1L, The softening temperature is 30°C, and the softening time is 30 minutes; add softened down to water, and add glutamine transaminase, the mass ratio of down to water is 1:35, and the dosage ratio of glutamine transaminase to water is 0.4: 1L, the crosslinking temperature is 45°C, the crosslinking time is 60min, drained, dried, and ready for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com