Gantry-type double-tube board inserting machine and boarding inserting method thereof

A gantry type, inserting machine technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problem that the insertion depth cannot be automatically recorded and timely fed back, the insertion depth of plastic drainage boards is not uniform, and the verticality of the intubation can be solved. It is difficult to guarantee and other problems to achieve the effect of facilitating construction management and quality control, improving operation efficiency and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing.

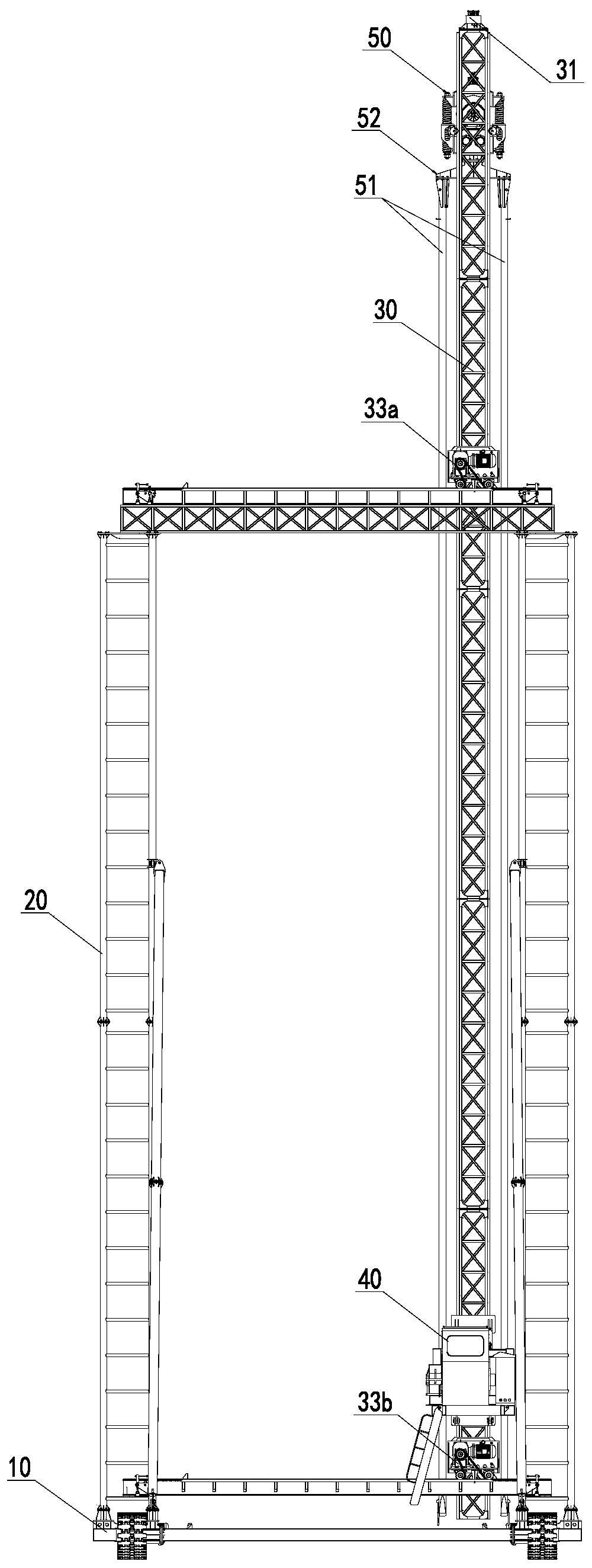

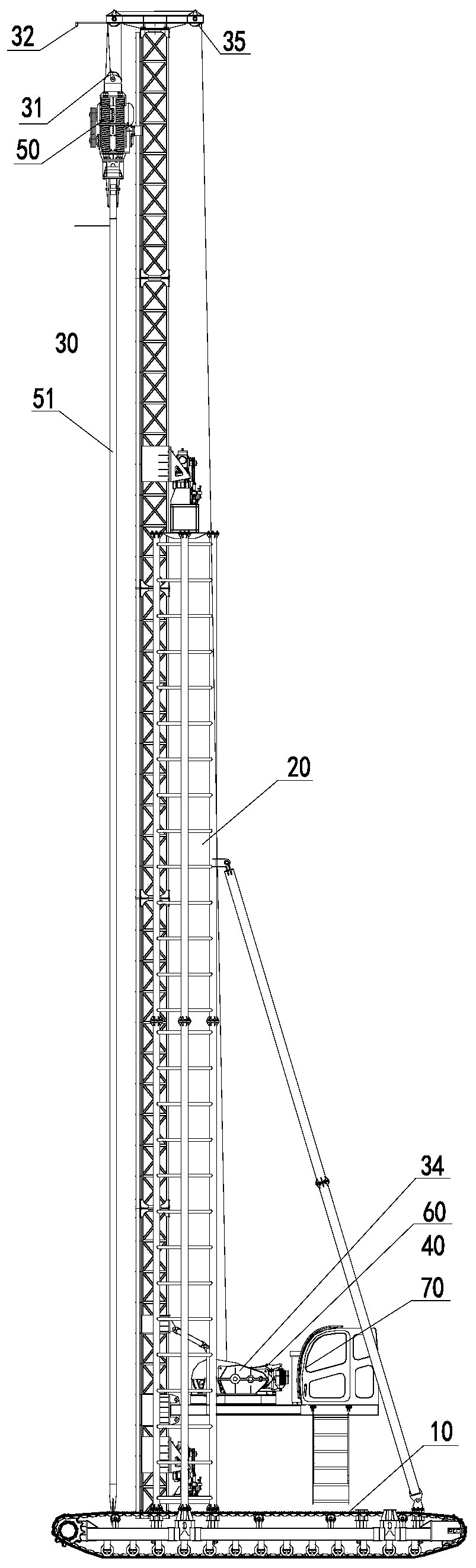

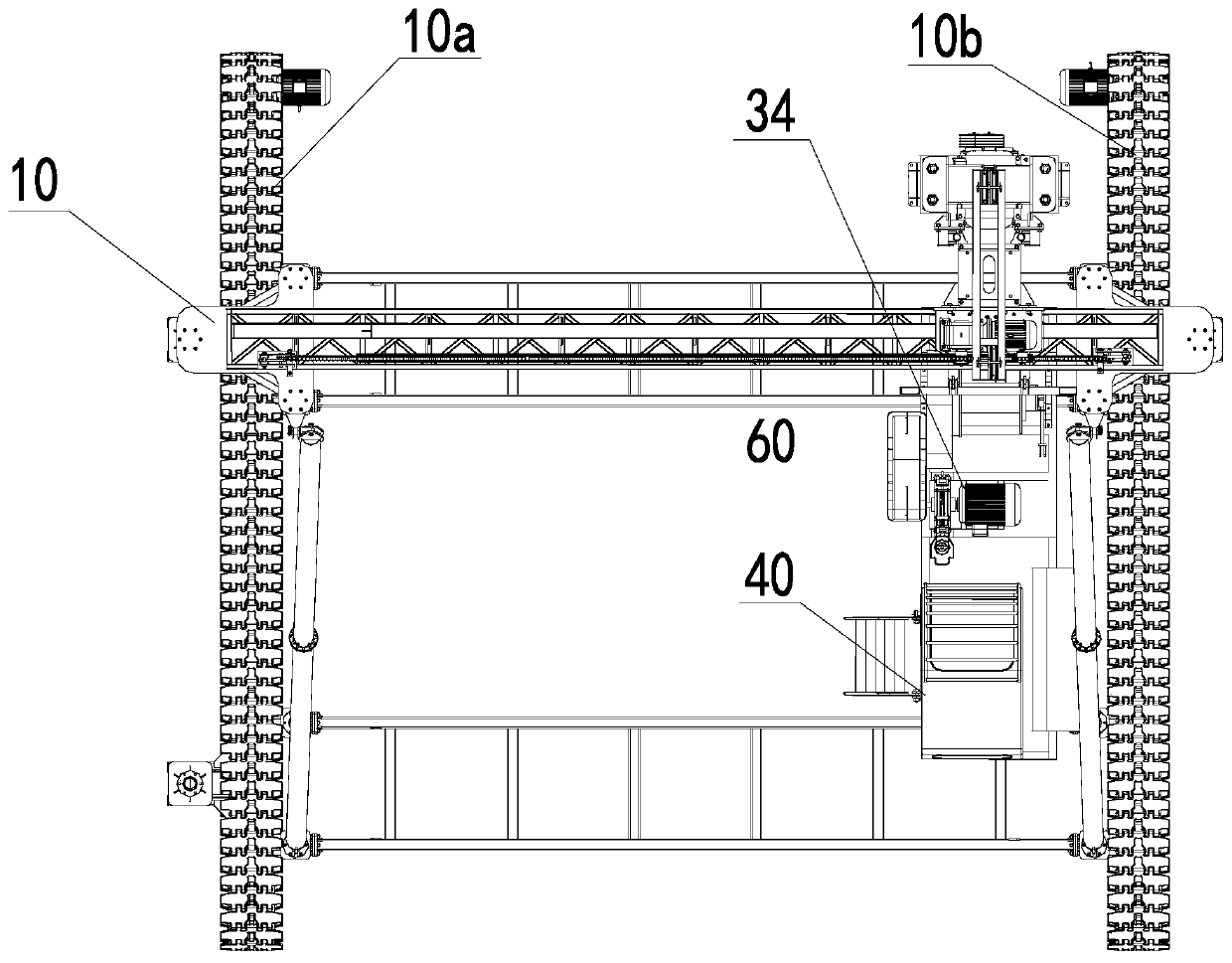

[0045] see Figure 1 to Figure 4 , the gantry-type double-pipe insertion machine of the present invention includes a crawler belt traveling device 10, a gantry-type frame 20, a main tower 30, a hammer 50, an intubation hanger 52 and a control room 40; wherein,

[0046]The crawler belt traveling device 10 comprises a crawler belt frame and a left crawler belt 10a and a right crawler belt 10b installed on both sides of the crawler belt frame, and the left crawler belt 10a and the right crawler belt 10b are driven by the left crawler belt motor and the right crawler belt motor in one-to-one correspondence;

[0047] The gantry frame 20 is installed on the crawler walking device 10, and the gantry frame 20 includes columns on both sides, upper beams and lower beams. The columns on both sides are spliced by multi-section steel structure space trusses, and the On the upper beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com