Method for improving performance of sintered NdFeB magnet

A magnetic performance, NdFeB technology, applied in the direction of magnetic materials, magnetic objects, inductance/transformer/magnet manufacturing, etc., can solve the problems of limited performance improvement, high diffusion activation energy, shallow diffusion depth, etc., to achieve reduced dosage, The process is simple and the effect of reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

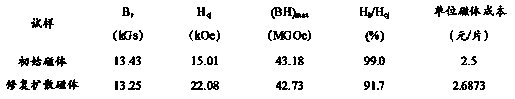

Embodiment 1

[0022] (1) Slice the sintered NdFeB magnet into 10*20*6 mm blocks.

[0023] (2) Use 600 CW, 1000CW, 1500CW, and 2000CW sandpaper to polish the 6 surfaces of the magnet in sequence, and then put them in alcohol for ultrasonic vibration cleaning; then ultrasonically degrease the magnet in a degreasing solution at 50 °C 3min, followed by washing with water for 5-15 s.

[0024] (3) Place the magnet in a nitric acid solution with a concentration of 3% and shake it for 10-20 s. After taking it out, wash it twice with water for 5-15 s each time, and then perform ultrasonic vibration treatment until the magnet is observed. After the surface oxide skin has completely fallen off, it is taken out and dried at a temperature of 40°C for 20 minutes. Other methods can also be used to completely peel off the oxide skin on the surface of the magnet.

[0025] (4) MgO powder and Dy 2 o 3 The powder is mixed, and the ratio of the atomic number of Mg to the atomic number of Dy in the mixture i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com