Portable spherical direct methanol fuel cell

A methanol fuel cell, portable technology, applied in the direction of fuel cells, fuel cell parts, circuits, etc., can solve the problems of cumbersome production methods, reduce the performance of membrane electrodes, and difficult assembly, so as to save time and economic costs and improve carbon dioxide Manage and reduce the effects of toxic by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings. However, it should be noted that the protection scope of the present invention is not limited to the scope described in the following examples.

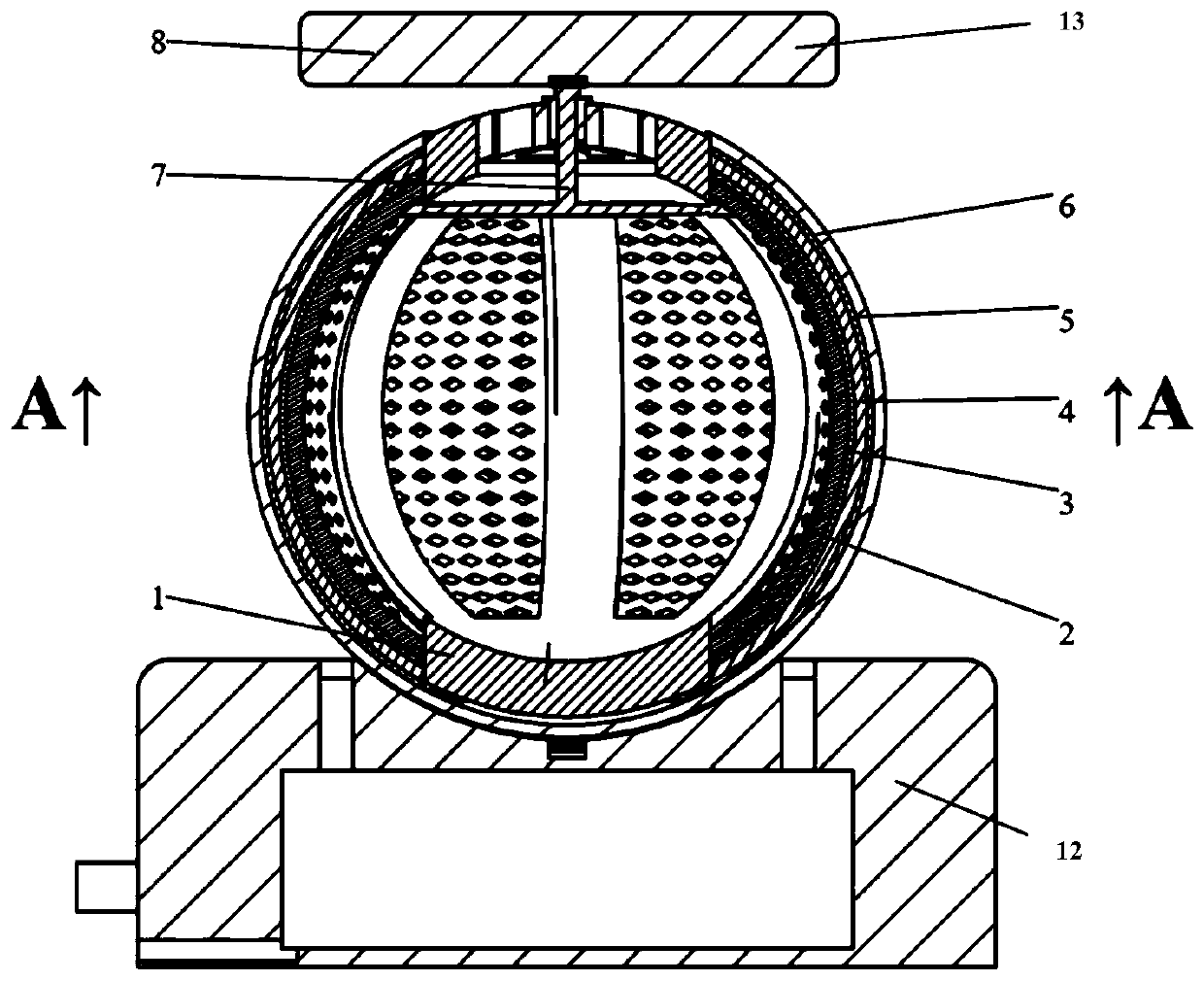

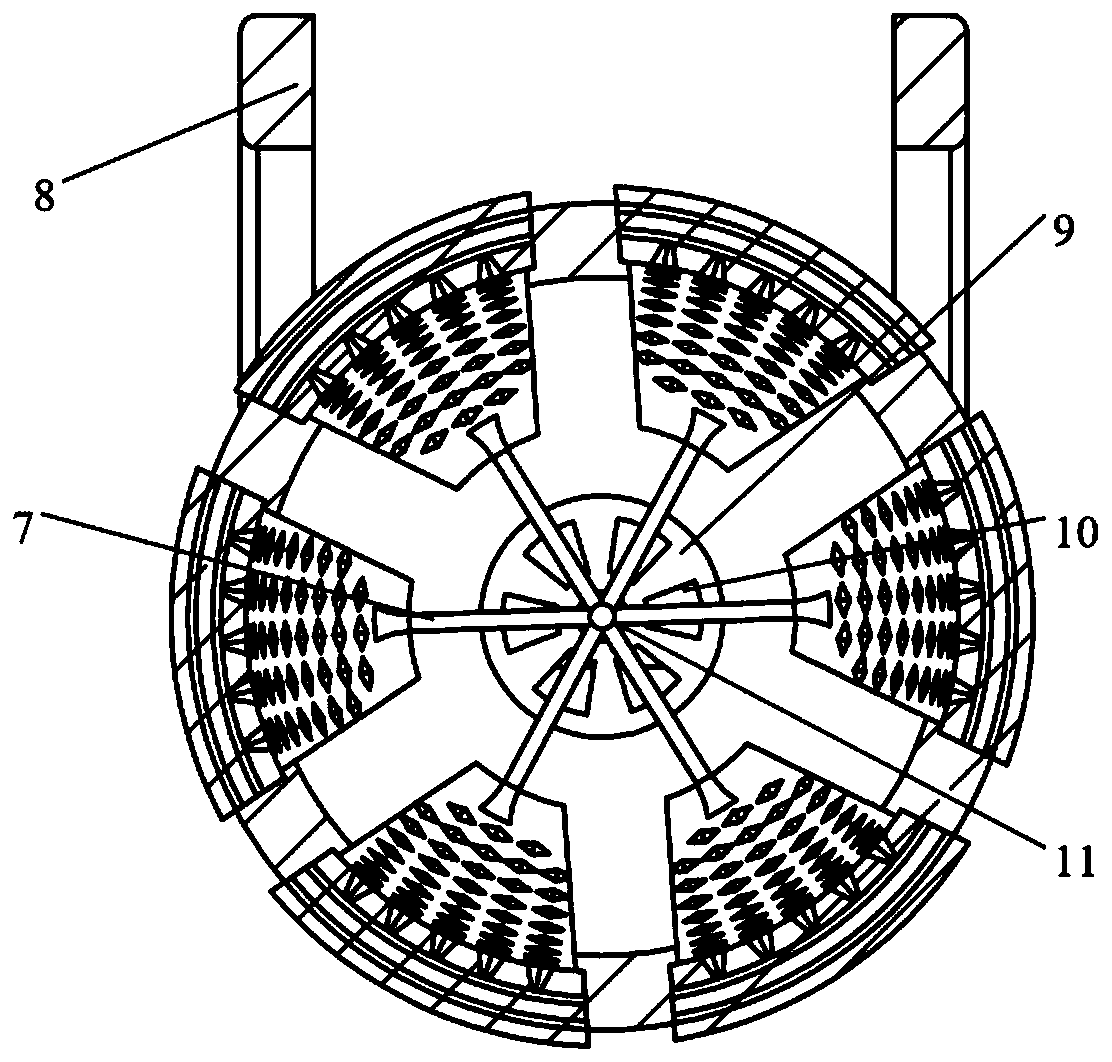

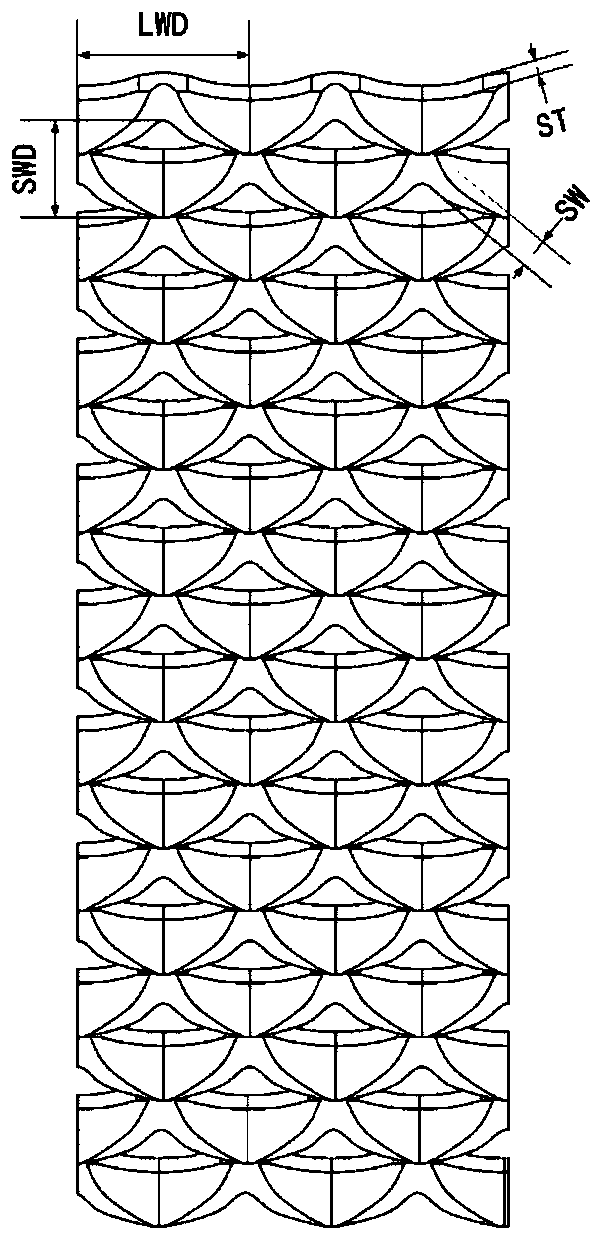

[0035] Such as figure 1 and figure 2 As shown, a portable spherical direct methanol fuel cell includes a base 8, a grid hole casing 1 arranged on the base 8, a plurality of anode collector plates 2, a catalytic layer 3, an alcohol barrier layer 4, a membrane electrode 5, Cathode current collector 6. The grid hole housing 1 is spherical in shape with a closed lower end, an open upper end and an end cover 9. The circumferential wall of the grid hole housing 1 is evenly provided with a number of arc-shaped grids parallel to the meridian. The left and right sides of the arc-shaped grid are provided with arc-shaped slots for limiting the anode collector plate 2 . The grid ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com