Preparation process of pre-stressed concrete pipe pile

A technology of concrete pipe pile and preparation process, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of pipe pile strength, adverse effect on durability, poor impermeability performance of pipe pile, cracking and damage of matrix, etc. Improve impermeability and other properties, improve erosion resistance, improve the effect of impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

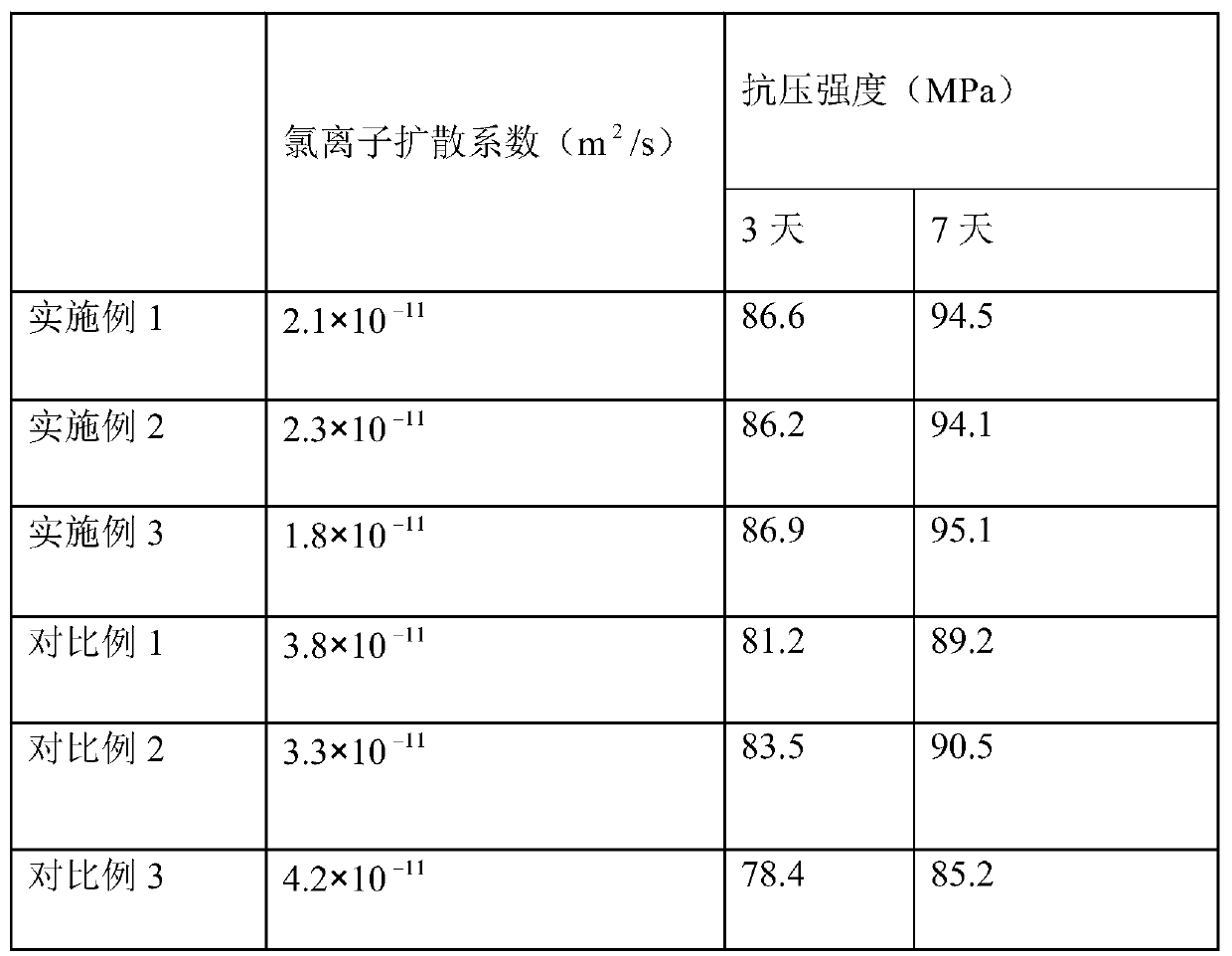

Examples

Embodiment 1

[0026] A kind of preparation technology of prestressed concrete pipe pile of the present embodiment comprises the following steps:

[0027] Step 1, weigh the following raw materials in parts by weight: 30 parts of Portland cement, 10 parts of ultrafine mineral powder, 55 parts of sand, 6 parts of tetramethyl quaternary ammonium salt, 5 parts of modified calcium-based rectorite, spirulina polysaccharide 1 part, 1 part of cubic alumina, 0.2 part of polypyrrole tube, 0.1 part of nano boron fiber, 60 parts of deionized water;

[0028] Step 2: Add the Portland cement, ultrafine mineral powder, and sand in step 1 into the high-speed mixer in sequence, the mixing speed is 100r / min, mix for 20min, and then add tetramethyl quaternary ammonium salt, modified calcium Base rectorite, spirulina polysaccharide, cubic aluminum oxide, polypyrrole tube, nano-boron fiber, the stirring speed is increased to 300r / min, and stirred for 40min to obtain the initial material;

[0029] Step 3: add dei...

Embodiment 2

[0039] A kind of preparation technology of prestressed concrete pipe pile of the present embodiment comprises the following steps:

[0040] Step 1, weigh the following raw materials by weight: 40 parts of Portland cement, 20 parts of ultrafine mineral powder, 65 parts of sand, 12 parts of tetramethyl quaternary ammonium salt, 10 parts of modified calcium-based rectorite, spirulina polysaccharide 3 parts, 2 parts of cubic alumina, 0.8 parts of polypyrrole tube, 0.7 parts of nano boron fiber, 100 parts of deionized water;

[0041] Step 2: Add the Portland cement, ultrafine mineral powder, and sand in step 1 into the high-speed mixer in turn, the mixing speed is 200r / min, mix for 30min, and then add tetramethyl quaternary ammonium salt, modified calcium Base rectorite, spirulina polysaccharide, cubic aluminum oxide, polypyrrole tube, nano-boron fiber, the stirring speed is increased to 400r / min, and stirred for 50min to obtain the initial material;

[0042] Step 3: add deionized...

Embodiment 3

[0052] A kind of preparation technology of prestressed concrete pipe pile of the present embodiment comprises the following steps:

[0053] Step 1, weigh the following raw materials by weight: 35 parts of Portland cement, 15 parts of superfine mineral powder, 55-65 parts of sand, 9 parts of tetramethyl quaternary ammonium salt, 7.5 parts of modified calcium-based rectorite, spiral 1 part of algae polysaccharide, 1.5 parts of cubic alumina, 0.5 part of polypyrrole tube, 0.4 part of nano boron fiber, 80 parts of deionized water;

[0054] Step 2: Add Portland cement, ultra-fine mineral powder, and sand in step 1 into the high-speed mixer in sequence, the mixing speed is 150r / min, mix for 25min, and then add tetramethyl quaternary ammonium salt, modified calcium Base rectorite, spirulina polysaccharide, cubic aluminum oxide, polypyrrole tube, nano-boron fiber, stirring speed increased to 350r / min, stirring for 45min, to obtain the initial material;

[0055] Step 3, add deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com