A preparation method of high-efficiency heat storage unit based on hierarchical porous ceramics

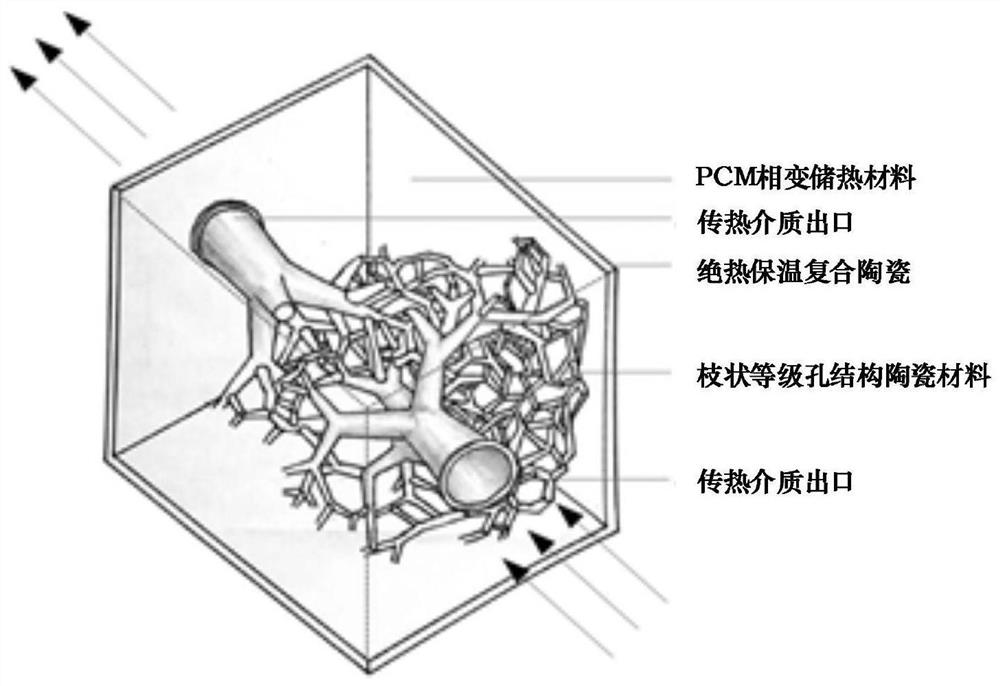

A grade hole and heat storage technology, which is applied in energy and various heat storage fields, can solve the problems of thermal conductivity and heat storage density of heat storage materials, etc., so as to improve material latent heat, excellent high-temperature service performance, and improve The effect of heat storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for preparing a high-efficiency heat storage unit based on hierarchical porous ceramics, comprising the following steps:

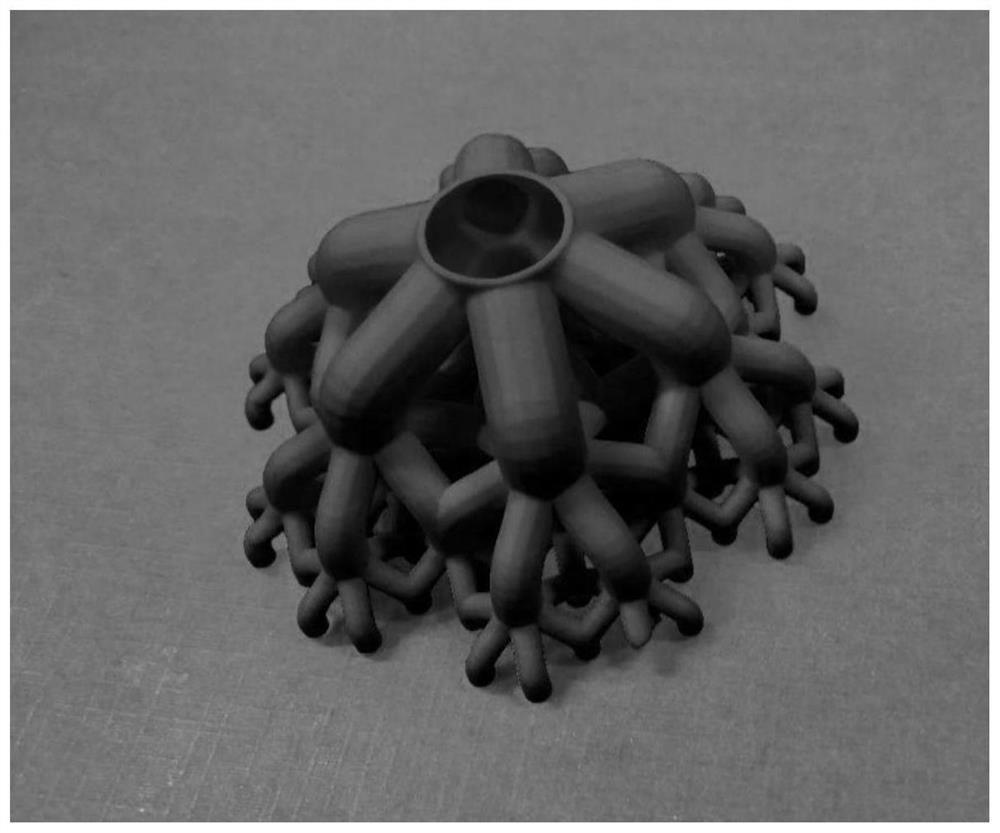

[0022] 1) Design graded hole structure parameters: Design and select graded hole structure parameters according to Murray's law. A complete heat storage unit with graded hole structure is composed of 4 grades of holes, which are numbered as A1, A2, A3, A4 grade holes according to the hole diameter from large to small, and the hole diameter is D in turn. 1 =100mm, D 2 =55.03mm, D 3 =30.29mm, D 4 =16.67mm, the angle between adjacent holes of the same level is 47°, the hole shape is circular, and each level hole is divided into 6 secondary holes (k n =6), the aperture D of the holes at all levels satisfies Murray's law

[0023] 2) Preparation of hierarchical porous ceramic matrix: according to the selected hierarchical porous structure parameters, cermet TiB 2 Powder (particle size = 2μm) is the main raw material, and TiB is added 2 Po...

Embodiment 2

[0027] Basically the same as embodiment 1, the difference is: Si 3 N 4 The amount of powder added is TiB 2 The mass of the powder is 1.0 wt%, and it is fired at 1650°C in an argon atmosphere; the Al-Cu alloy with a phase transition temperature of 620°C is filled outside the ceramic matrix with a hierarchical pore structure.

[0028] After testing, the heat storage density of the high-efficiency heat storage unit based on hierarchical porous ceramics is 1944kJ / kg, and the thermal conductivity is 28W / (m·K).

Embodiment 3

[0030] Basically the same as embodiment 1, the difference is: Si 3 N4 The amount of powder added is TiB 2 The mass of the powder is 3.0wt%, and it is fired at 1750°C in an argon atmosphere.

[0031] After testing, the heat storage density of the high-efficiency heat storage unit based on hierarchical porous ceramics is 1877kJ / kg, and the thermal conductivity is 21W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

| heat storage density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com