High-toughness extrusion casting aluminum alloy and preparation method thereof

A technology of squeeze casting and aluminum alloy, which is applied in the field of high strength and toughness squeeze casting aluminum alloy and its preparation, can solve the problems of waste of precious metal elements, etc., and achieve the effect of increasing use value and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

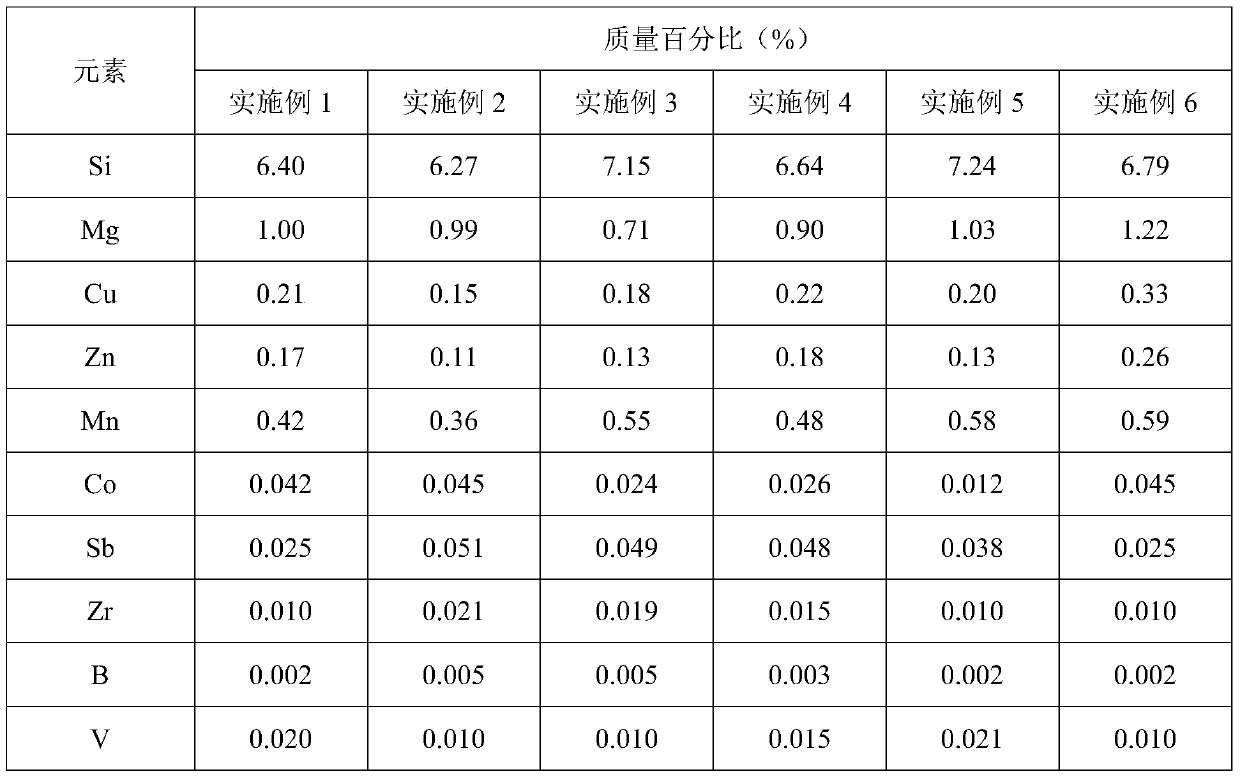

Examples

Embodiment 1

[0061] The composition and mass percentage of the raw materials used in this example of high strength and toughness squeeze casting aluminum alloy are: 75% 4xxx series aluminum alloy scrap, 15.1% 5xxx series aluminum alloy scrap, 4.3% 2xxx series aluminum alloy scrap, 2.6% 7xxx Aluminum alloy scrap, 2.5% 3xxx series aluminum alloy scrap, 0.2% aluminum zirconium boron master alloy, 0.1% aluminum antimony master alloy and 0.2% aluminum vanadium master alloy.

[0062] Among them, the chemical composition and mass percentage of each raw material are as follows:

[0063]The chemical composition and mass percentage of 4xxx series aluminum alloy scrap are: Si 8.51%, Mg 0.26%, Mn 0.37%, Fe≤0.6%, the balance is Al and other unavoidable impurity elements, and the individual content of other impurity elements is ≤0.1 %, total amount ≤0.5%;

[0064] The chemical composition and mass percentage of 5xxx series aluminum alloy scrap are: Mg 4.54%, Mn 0.59%, Co 0.28%, Fe ≤ 0.4%, the balance i...

Embodiment 2

[0079] The composition and mass percentage of the raw materials used for the high-strength extrusion-casting aluminum alloy in this example are: 78% 4xxx series aluminum alloy scrap, 15% 5xxx series aluminum alloy scrap, 3% 2xxx series aluminum alloy scrap, 2% 7xxx Aluminum alloy scrap, 1.3% 3xxx series aluminum alloy scrap, 0.4% aluminum zirconium boron master alloy, 0.2% aluminum antimony master alloy and 0.1% aluminum vanadium master alloy.

[0080] Among them, the chemical composition and mass percentage of each raw material are as follows:

[0081] The chemical composition and mass percentage of 4xxx series aluminum alloy scrap are: Si 8.01%, Mg 0.39%, Mn 0.24%, Fe ≤0.6%, the balance is Al and other unavoidable impurity elements, and the individual content of other impurity elements ≤0.1 %, total amount ≤0.5%;

[0082] The chemical composition and mass percentage of 5xxx series aluminum alloy scrap are: Mg 4.02%, Mn 0.95%, Co 0.30%, Fe ≤0.4%, the balance is Al and other ...

Embodiment 3

[0097] The composition and mass percentage of the raw materials used for the high-strength extrusion-casting aluminum alloy in this example are: 80% 4xxx series aluminum alloy scrap, 12% 5xxx series aluminum alloy scrap, 4% 2xxx series aluminum alloy scrap, 2% 7xxx Aluminum alloy scrap, 1.3% 3xxx series aluminum alloy scrap, 0.4% aluminum zirconium boron master alloy, 0.2% aluminum antimony master alloy and 0.1% aluminum vanadium master alloy.

[0098] Among them, the chemical composition and mass percentage of each raw material are as follows:

[0099] The chemical composition and mass percentage of 4xxx series aluminum alloy scrap are: Si 8.9%, Mg 0.2%, Mn 0.5%, Fe≤0.6%, the balance is Al and other unavoidable impurity elements, and the individual content of other impurity elements is ≤0.1% , the total amount ≤ 0.5%;

[0100] The chemical composition and mass percentage of 5xxx series aluminum alloy scrap are: Mg 4.5%, Mn 0.9%, Co 0.2%, Fe≤0.4%, the balance is Al and other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com