Ultra-low carbon steel coil plate for ultra-thin shell of oil filter and manufacturing method thereof

An oil filter, ultra-low carbon steel technology, applied in the field of metal material manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment produces an ultra-low carbon steel coil with a thickness of 0.44 mm for an ultra-thin casing of an oil filter, and the ultra-low carbon steel coil:

[0061] S1, through converter smelting, RH furnace refining, continuous casting into slabs with the following weight percentages: C: 0.0048%, Si: 0.019%, Mn: 0.46%, P: 0.012%, S: 0.008%, Al: 0.046%, Ti: 0.066%, N: 0.0028%, the rest is Fe and other unavoidable impurities;

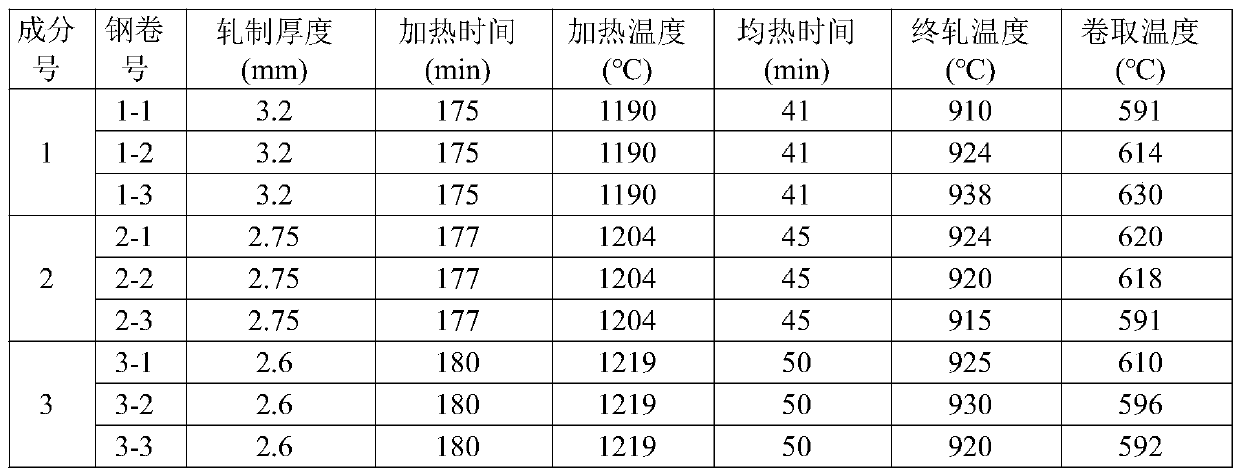

[0062] S2, hot rolling: the slab is heated to 1190°C, the heating time is 175min, the soaking time is 41min, and then the hot-rolled plate is obtained through rough rolling and finish rolling, and the finish rolling temperature is 910-938°C, and then the The hot-rolled sheet is subjected to laminar cooling, and coiled into a hot-rolled coil after cooling at a coiling temperature of 591 to 630°C;

[0063] S3, cold rolling: pickling, rolling, cold rolling reduction rate 86.25%;

[0064] S4, annealing treatment: the temperature of the soaking...

Embodiment 2

[0067] This embodiment produces an ultra-low carbon steel coil with a thickness of 0.33 mm for an ultra-thin casing of an oil filter, and the ultra-low carbon steel coil:

[0068] S1, through converter smelting, RH furnace refining, continuous casting into slabs with the following weight percentages: C: 0.0030%, Si: 0.015%, Mn: 0.53%, P: 0.010%, S: 0.005%, Al: 0.070%, Ti: 0.070%, N: 0.0025%, the rest is Fe and other unavoidable impurities;

[0069] S2, hot rolling: the slab is heated to 1204°C, the heating time is 177min, the soaking time is 45min, and then the hot-rolled plate is obtained through rough rolling and finish rolling, and the finish rolling temperature is 915-924°C, and then the The hot-rolled sheet is subjected to laminar cooling, and coiled into a hot-rolled coil after cooling at a coiling temperature of 591-620°C;

[0070] S3, cold rolling: pickling, rolling, cold rolling reduction rate 88.0%;

[0071] S4, annealing treatment: the temperature of the soaking s...

Embodiment 3

[0074] This embodiment produces an ultra-low carbon steel coil with a thickness of 0.30mm for an ultra-thin casing of an oil filter, and the ultra-low carbon steel coil:

[0075] S1, through converter smelting, RH furnace refining, continuous casting into slabs with the following weight percentages: C: 0.0038%, Si: 0.016%, Mn: 0.50%, P: 0.008%, S: 0.003%, Al: 0.060%, Ti: 0.082%, N: 0.0020%, the rest is Fe and other unavoidable impurities;

[0076] S2, hot rolling: the slab is heated to 1210°C, the heating time is 180min, the soaking time is 50min, and then the hot-rolled plate is obtained through rough rolling and finish rolling, and the finish rolling temperature is 920-930°C, and then the The hot-rolled sheet is subjected to laminar cooling, and coiled into a hot-rolled coil after cooling, with a coiling temperature of 592-610°C;

[0077] S3, cold rolling: pickling, rolling, cold rolling reduction rate 88.46%;

[0078] S4, annealing treatment: the temperature of the soakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com