Method for preparing recyclable paper bag raw material

A raw material and paper bag technology, which is applied in the field of preparation of recyclable paper bag raw materials, can solve the problems of easy breakage, serious problems in the later stage, and pollute the environment, and achieve the effect of improving the resistance to crushing and rubbing, and reducing white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

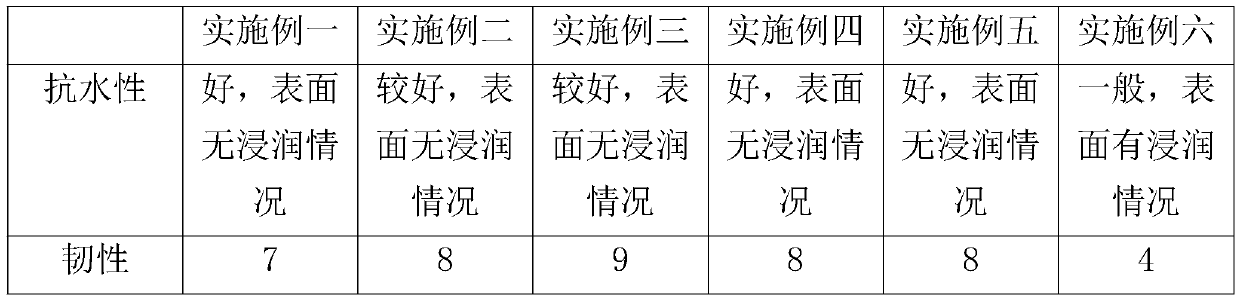

Examples

Embodiment 1

[0020] A preparation method for making recyclable paper bag raw materials, comprising the following steps:

[0021] (1) Raw material pretreatment: select the fresh adult leaves of the vine of the lily family, soak them in the fermentation tank, use microorganisms to decompose the mesophyll, and maintain the temperature of the fermentation environment at 26-30°C. After the mesophyll is completely decomposed, filter to obtain the leaf film of the vine , wash and set aside.

[0022] (2) Broken leaf film: crush the leaf film obtained by the pretreatment with a crusher to 80-100 mesh.

[0023] (3) Pulp making: Pour the broken vine vine leaf film into the pulp making tank, add an equal amount of hydroxymethyl cellulose with a mass fraction of 0.1%, and stir evenly to make leaf film pulp.

[0024] (4) Water absorption: the leaf membrane slurry prepared in step (3) is absorbed into a uniform film shape with a vacuum carrier mold, and excess water is removed by a water absorption mach...

Embodiment 2

[0027] A preparation method for making recyclable paper bag raw materials, comprising the following steps:

[0028] (1) Raw material pretreatment: select the fresh adult leaves of the vine of the lily family, soak them in the fermentation tank, use microorganisms to decompose the mesophyll, and maintain the temperature of the fermentation environment at 26-30°C. After the mesophyll is completely decomposed, filter to obtain the leaf film of the vine , wash and set aside.

[0029] (2) Broken leaf film: crush the leaf film obtained by the pretreatment with a crusher to 80-100 mesh.

[0030] (3) Pulping: Pour the broken vine vine leaf film into the pulping tank, add an equivalent amount of hydroxymethylcellulose with a mass fraction of 0.15%, and stir evenly to make leaf film pulp.

[0031] (4) Water absorption: the leaf membrane slurry prepared in step (3) is absorbed into a uniform film shape with a vacuum carrier mold, and excess water is removed by a water absorption machine...

Embodiment 3

[0034] A preparation method for making recyclable paper bag raw materials, comprising the following steps:

[0035] (1) Raw material pretreatment: select the fresh adult leaves of the vine of the lily family, soak them in the fermentation tank, use microorganisms to decompose the mesophyll, and maintain the temperature of the fermentation environment at 26-30°C. After the mesophyll is completely decomposed, filter to obtain the leaf film of the vine , wash and set aside.

[0036] (2) Broken leaf film: crush the leaf film obtained by the pretreatment with a crusher to 80-100 mesh.

[0037] (3) Pulping: Pour the broken vine vine leaf film into the pulping tank, add an equal amount of 0.2% hydroxymethyl cellulose, and stir evenly to make leaf film pulp.

[0038] (4) Water absorption: the leaf membrane slurry prepared in step (3) is absorbed into a uniform film shape with a vacuum carrier mold, and excess water is removed by a water absorption machine.

[0039] (5) Hot pressing:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com