Terahertz frequency band reflection type polarization conversion device

A polarization conversion and reflective technology, applied in the direction of polarization components, instruments, optical components, etc., can solve the problems of low polarization conversion efficiency, loss, energy loss, etc., and achieve the effects of easy processing, low material cost, and simple graphic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

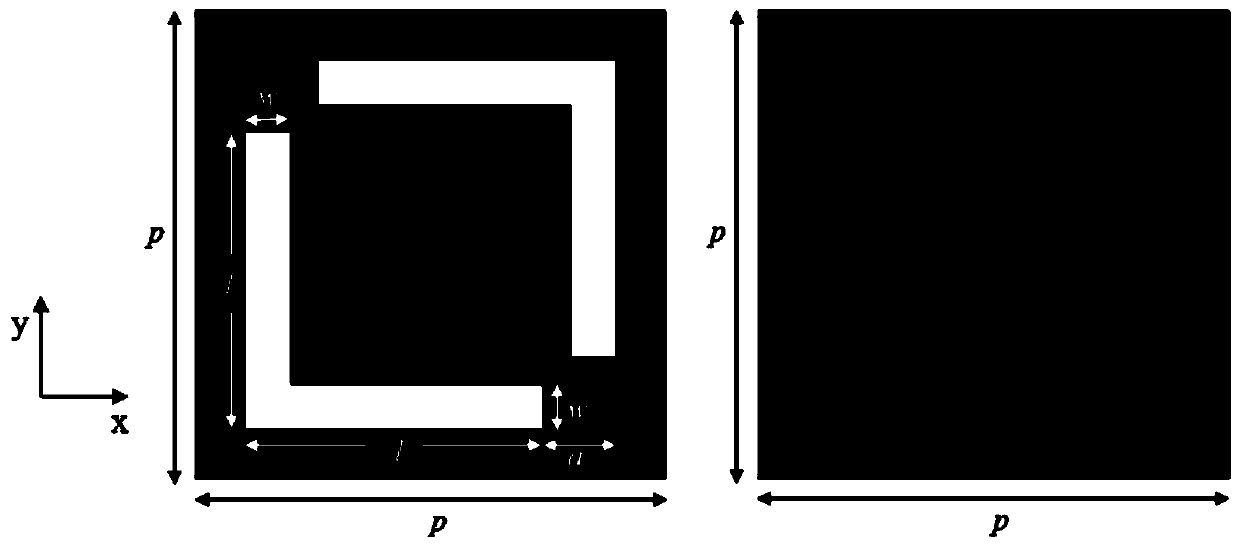

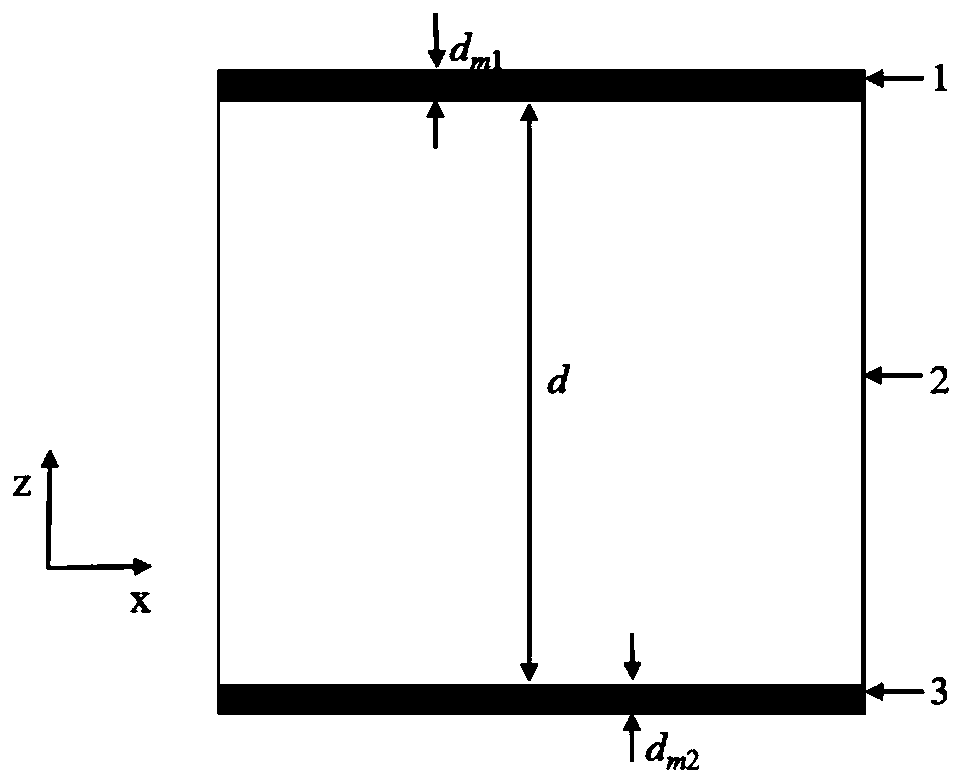

Method used

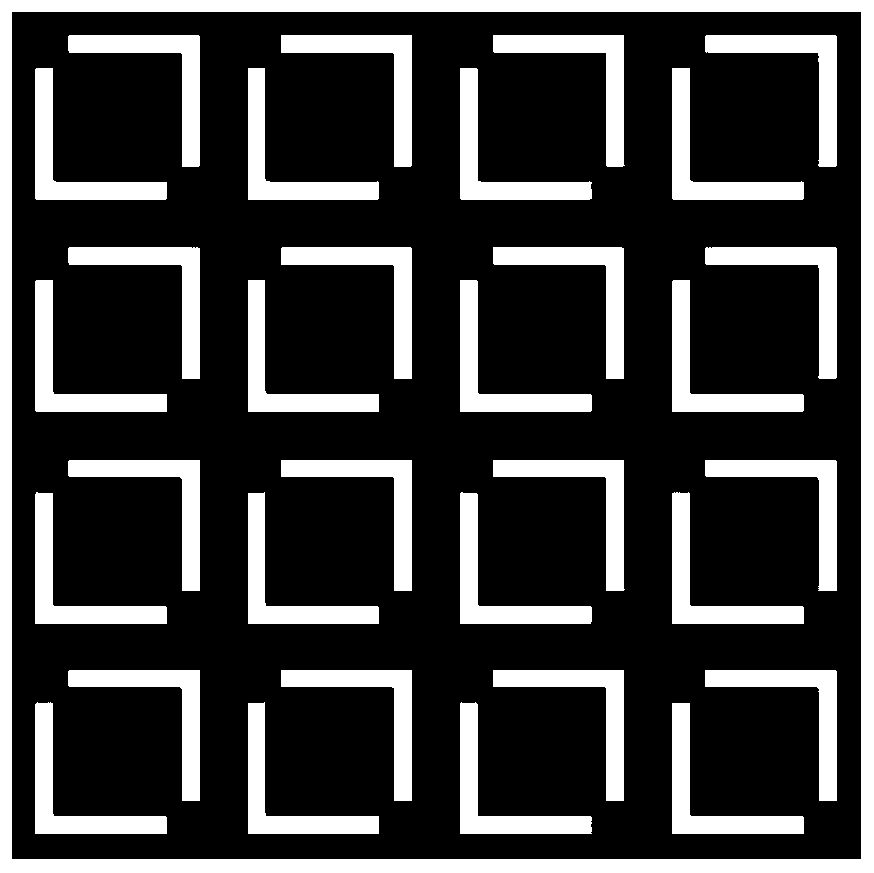

Image

Examples

Embodiment 1

[0038] Example 1: When horizontal linearly polarized waves are incident, at f 1 and f 2 produces vertically linearly polarized waves. Such as Figure 4 As shown in the reflected power spectrum of , when the incident wave is a horizontal linearly polarized wave, at the frequency point f 1 = 0.288THz and f 2 =0.342THz, the power of the horizontal linearly polarized wave in the reflected wave is 0, while the power of the vertically linearly polarized wave is close to 100%. Such as Figure 5 As shown, the polarization conversion rate at the frequency point is f 1 and f 2 The value at is close to 100%, which indicates that the energy of the incident wave undergoes almost complete linear polarization conversion at these two frequency points. by f 1 and f 2 From the electric field simulation at , it can be found that the resonance modes at the two frequency points are different. at lower frequencies f 1 At , the direction of the electric field in the two rectangular holes ...

Embodiment 2

[0039] Example 2: When horizontal linearly polarized waves are incident, at f 3 and f 6 produces right-handed circularly polarized waves. Such as Figure 6 As shown, at the frequency point f 3 = 0.283THz and f 6 =0.344THz, the reflectivity of the horizontally polarized wave and the vertically polarized wave in the reflected wave is both 50%, so the electric field strength of the two is equal. also because Figure 7 middle f 3 and f 6 The phase difference between the corresponding vertical electric field and the horizontal electric field is -90 degrees, so at f 3 and f 6 The reflected wave at is a right-handed circularly polarized wave.

Embodiment 3

[0040] Example 3: When horizontal linearly polarized waves are incident, at f 4 and f 5 produces a left-handed circularly polarized wave. Such as Figure 6 As shown, at the frequency point f 4 = 0.296THz and f 5 =0.340THz, the reflectivity of the horizontally polarized wave and the vertically polarized wave in the reflected wave is both 50%, so the electric field strengths of the two are equal. also because Figure 7 middle f 4 and f 5 The phase difference between the corresponding vertical electric field and the horizontal electric field is 90 degrees, so at f 4 and f 5 The reflected wave is a left-handed circularly polarized wave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com