Single-mode optical fiber and manufacturing method thereof

A single-mode optical fiber and preparation technology, which is applied in cladding optical fiber, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of increasing optical fiber Rayleigh scattering, viscosity fluctuations, and quartz glass density fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

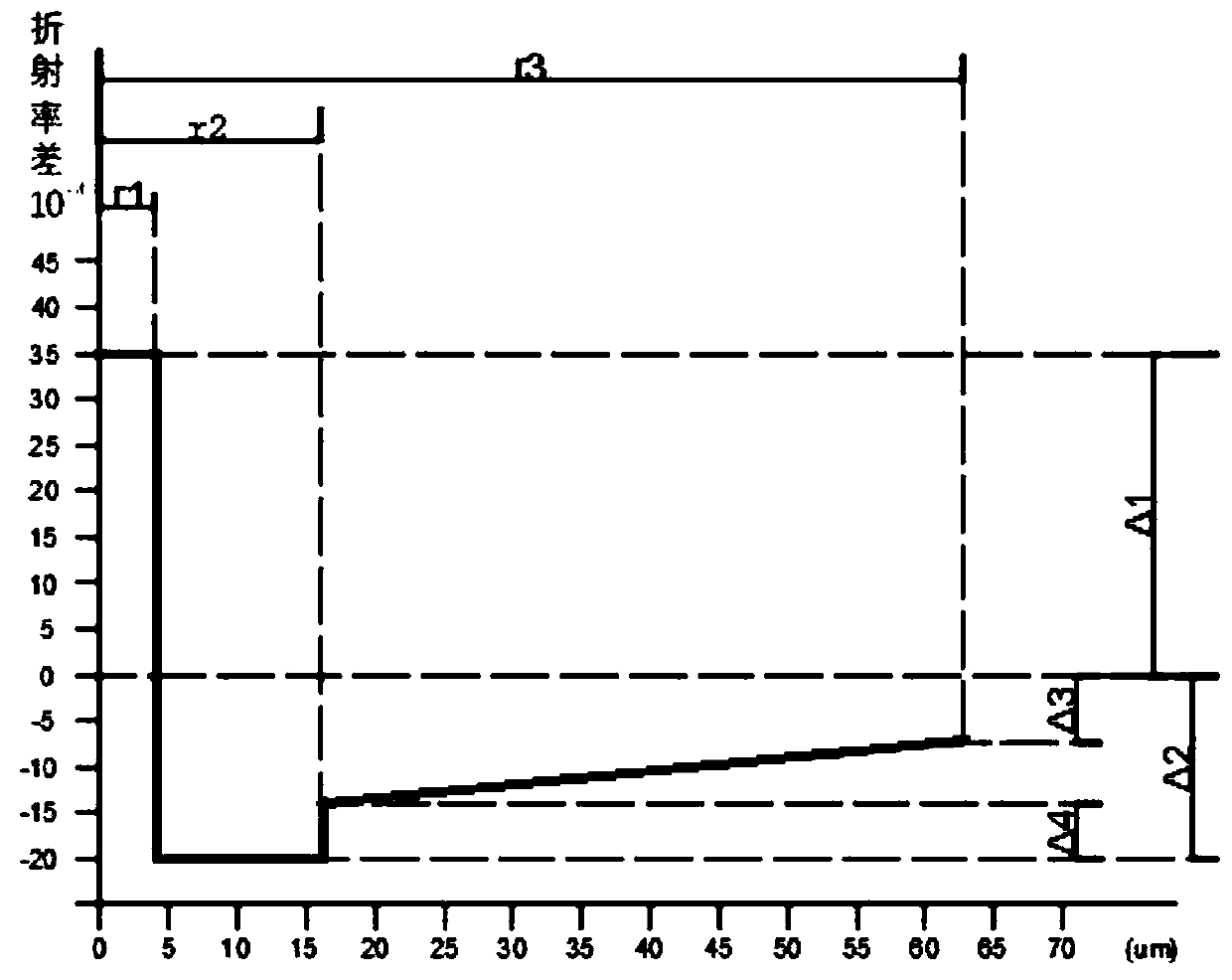

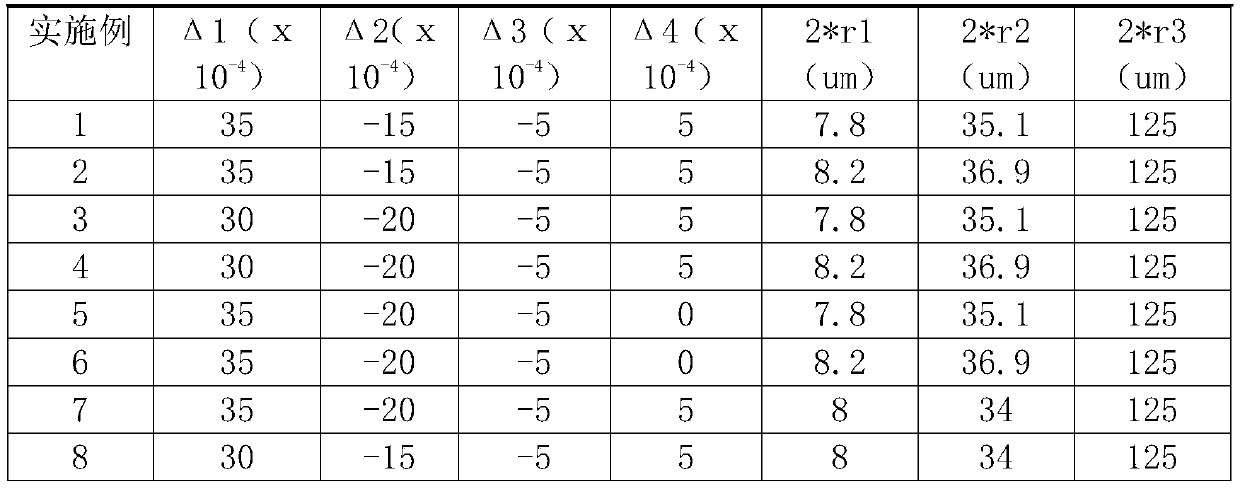

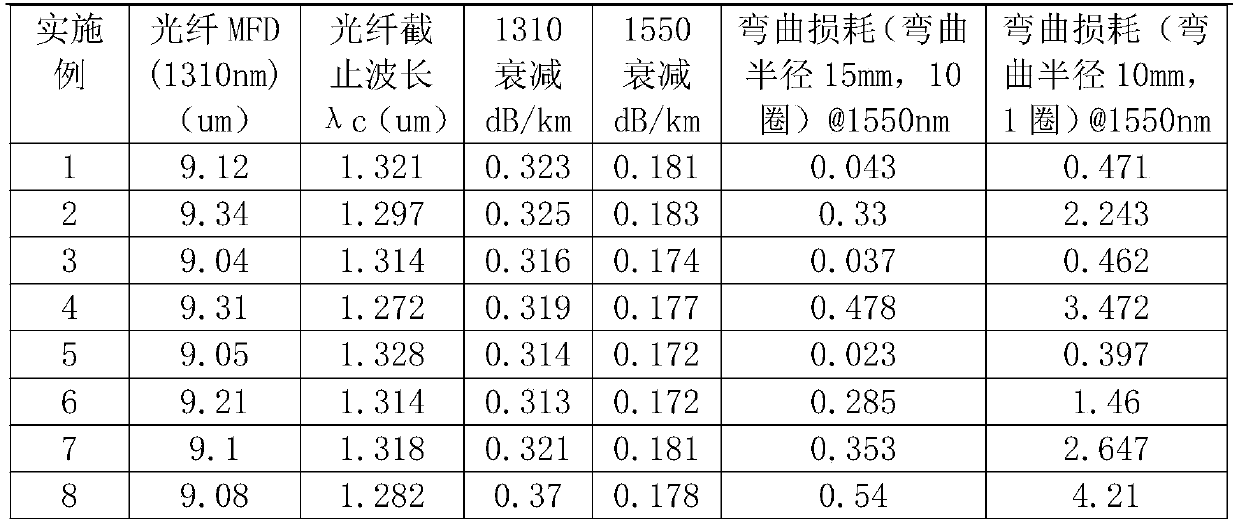

[0031] In the cross-section design of the optical fiber of the present invention, the core layer is doped with Ge element to increase the refractive index. Compared with pure SiO2 quartz glass, the refractive index difference is Δ1, and the core layer diameter is 2r1. The first cladding layer is uniformly doped with F elements to reduce the refractive index. The refractive index difference relative to pure SiO2 quartz glass is Δ2, and the diameter of the second cladding layer is 2r2. The second cladding layer is gradiently doped with F elements, which is used to match the core-in-pack viscosity difference of the optical fiber preform during the drawing process, and suppress the yearning expansion of F elements in the second cladding layer. The inner refractive index of the second cladding layer is relative to the second cladding layer. The refractive index difference of the cladding is Δ4, the refractive index difference of the outer refractive index of the second cladding rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com