Thermal protector calibration point center positioning method based on machine vision

A thermal protector and machine vision technology, applied in instruments, image data processing, computing, etc., can solve the problems of unsatisfactory detection effect, complex optical conditions of thermal protectors, and many interference factors, and achieve improved positioning accuracy and adaptability. Enhanced, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

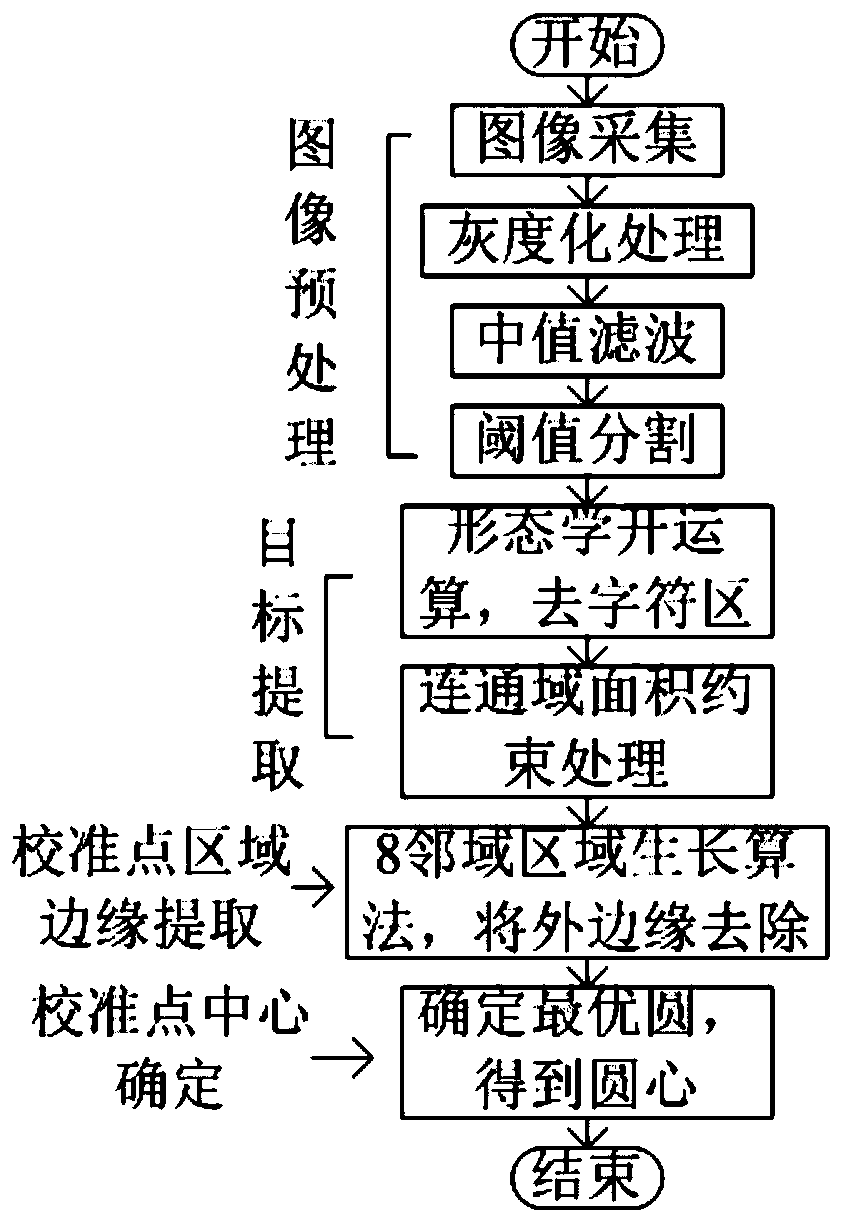

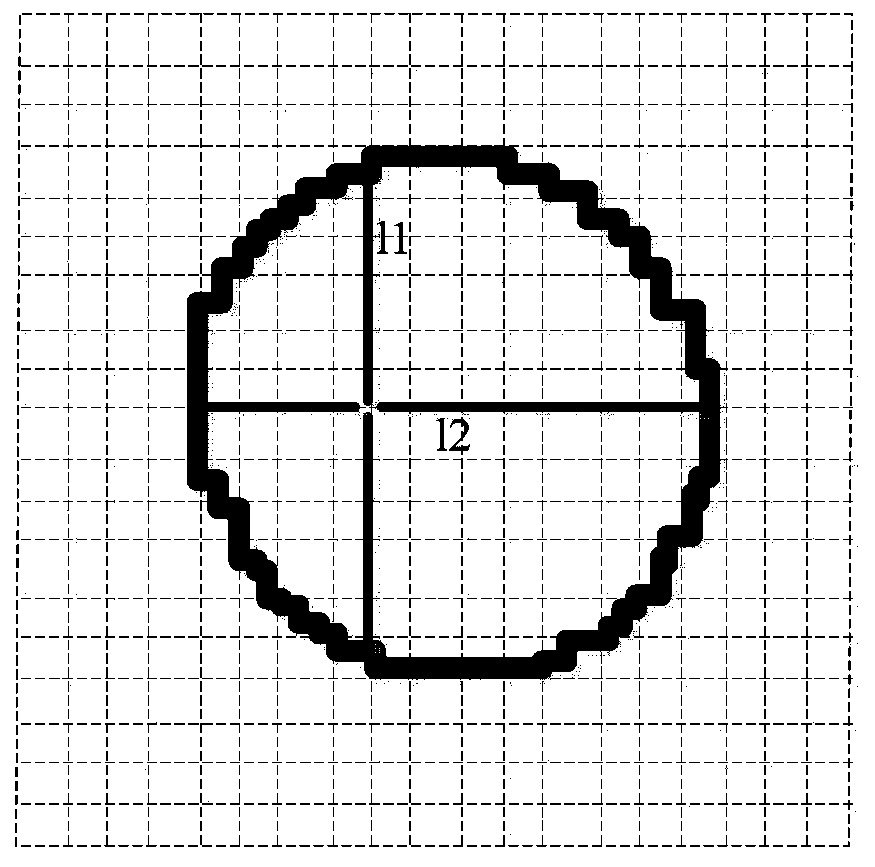

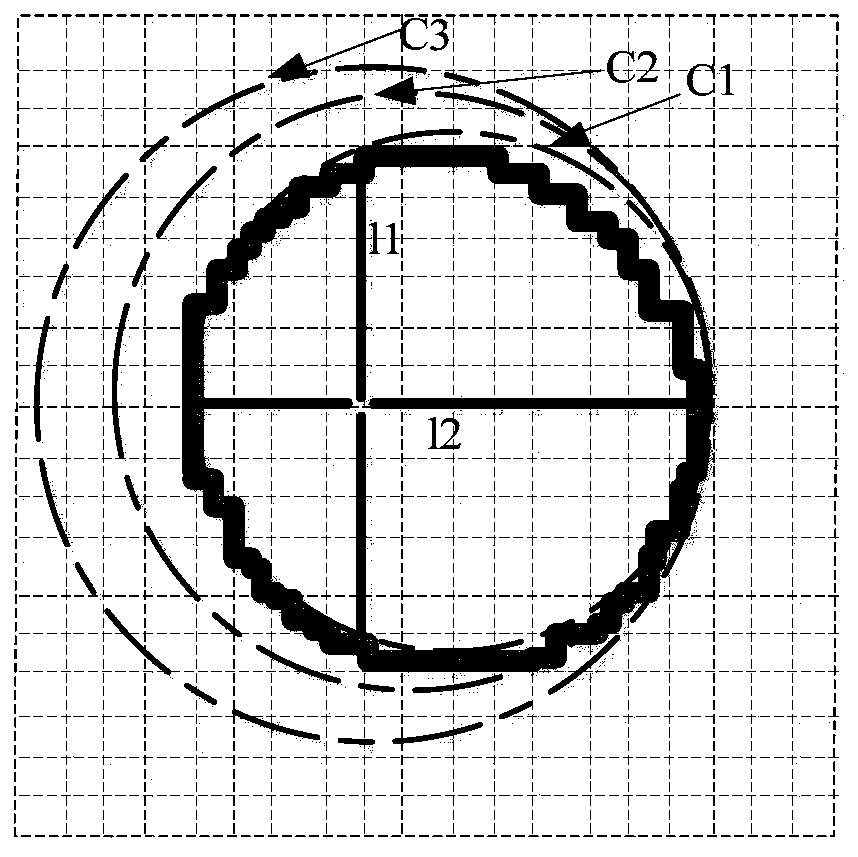

[0043] figure 1 Shown is the flow chart of the center positioning process of the calibration point in the present invention, including image preprocessing, target extraction, edge extraction of the calibration point area, and determination of the center position of the calibration point.

[0044] The image preprocessing includes the following steps: step 1, the diameter of the calibration point is about 1 mm, which belongs to the category of micro-size measurement, in order to obtain a clear image of the calibration point, use an industrial camera with a micro lens to collect images of the thermal protector; step 2, In order to reduce the amount of calculation and improve the calculation speed, grayscale processing is performed on the color image; step 3 is to eliminate the influence of metal reflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com