MEMS assembly

A shell and component technology, applied in the field of MEMS modules, can solve problems such as affecting the output signal and reducing the signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Before explaining the following embodiments in more detail with reference to the drawings, it is pointed out that identical, functionally identical or equivalent elements, objects, functional blocks and / or method steps in the various figures bear the same reference numerals, Descriptions of these elements, objects, functional blocks and / or method steps shown in different embodiments are thus interchangeable or applicable to each other.

[0014] Various embodiments will now be described in more detail with reference to the accompanying drawings, in which some embodiments are shown. In the drawings, the intensity of lines, layers and / or regions may not be drawn to scale for clarity.

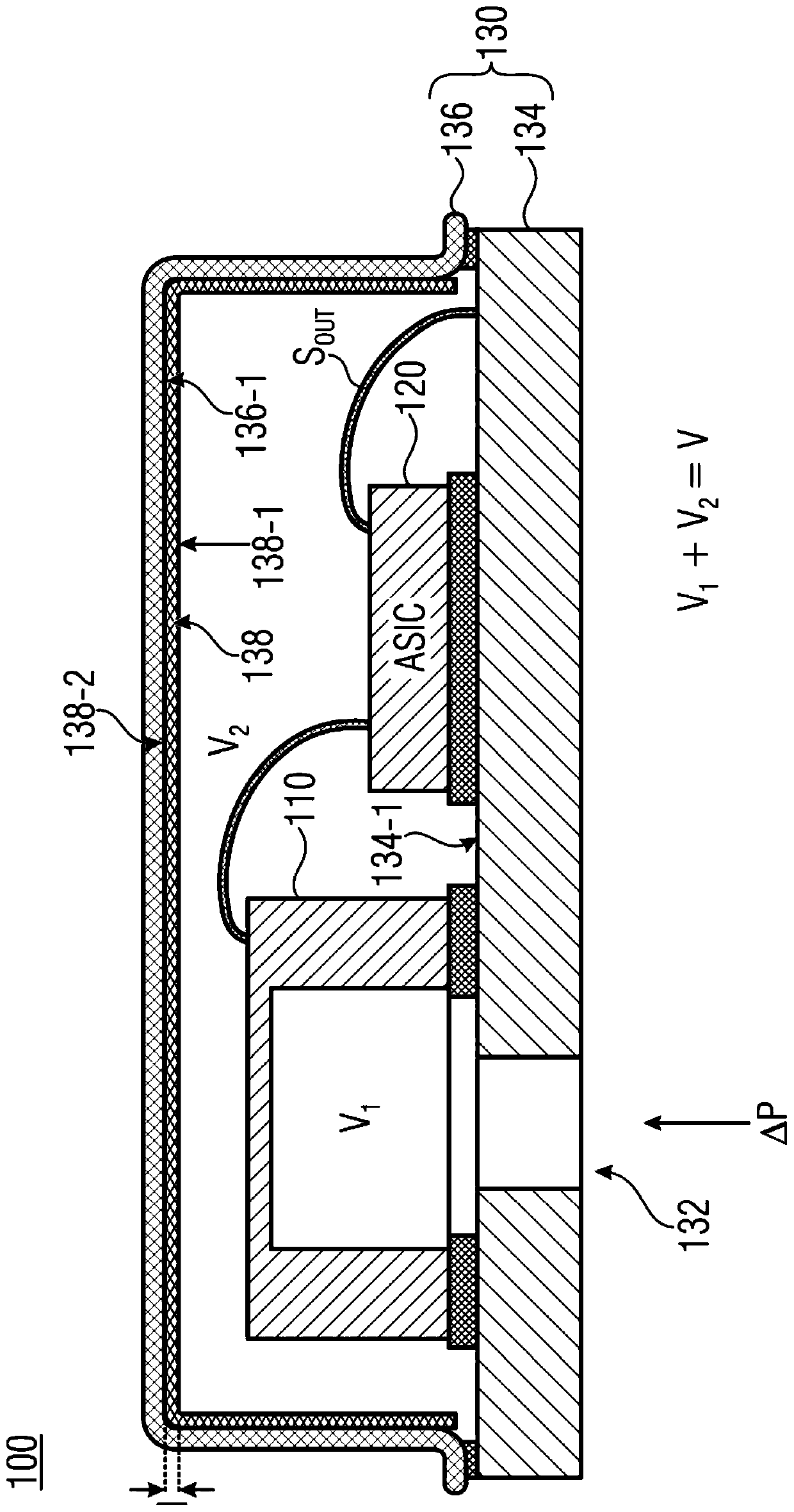

[0015] Refer below figure 1 , in a cross-sectional view, a MEMS module 100 is depicted in schematic diagram form with a MEMS component 110 and an optional circuit arrangement 120 (ASIC: Application Specific Integrated Circuit) electrically coupled to the MEMS component 110 . Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com