Polymeric surfactant heavy oil viscosity reducer and preparation method

A technology of surfactant and heavy oil viscosity reducer, which is applied in the field of oil recovery additives, can solve the problems of poor viscosity reduction effect of heavy oil viscosity reducer, reduce the viscosity of heavy oil, etc., achieve easy raw material acquisition, reduce crude oil viscosity, The effect of high natural dehydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

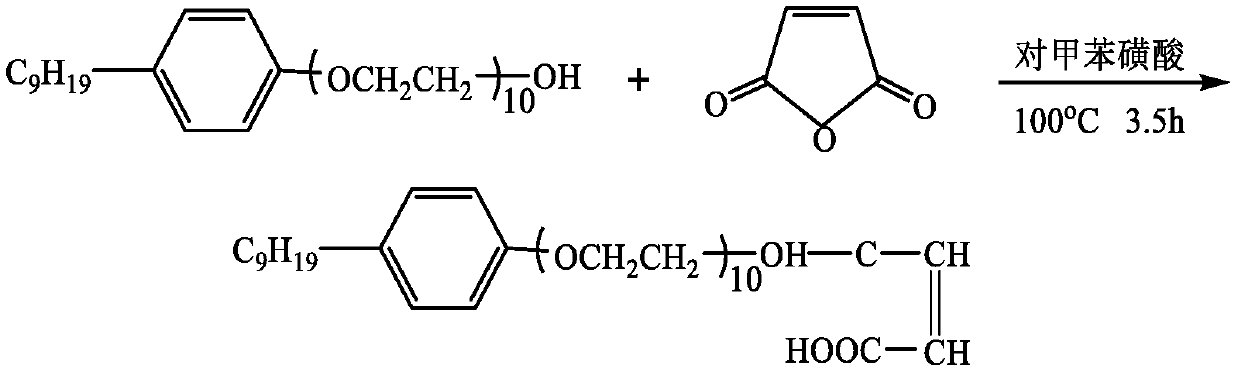

[0026] (1) Synthesis of monoester intermediates

[0027] Add maleic anhydride to nonylphenol polyoxyethylene ether in a molar ratio of 1:1 into a three-necked flask equipped with a stirring device, a condensing reflux device and a thermometer, raise the reaction temperature to 100°C, and then add 3% by weight of p-toluenesulfonic acid was used as a catalyst, and the reaction was performed with magnetic stirring for 3.5 hours to obtain an intermediate.

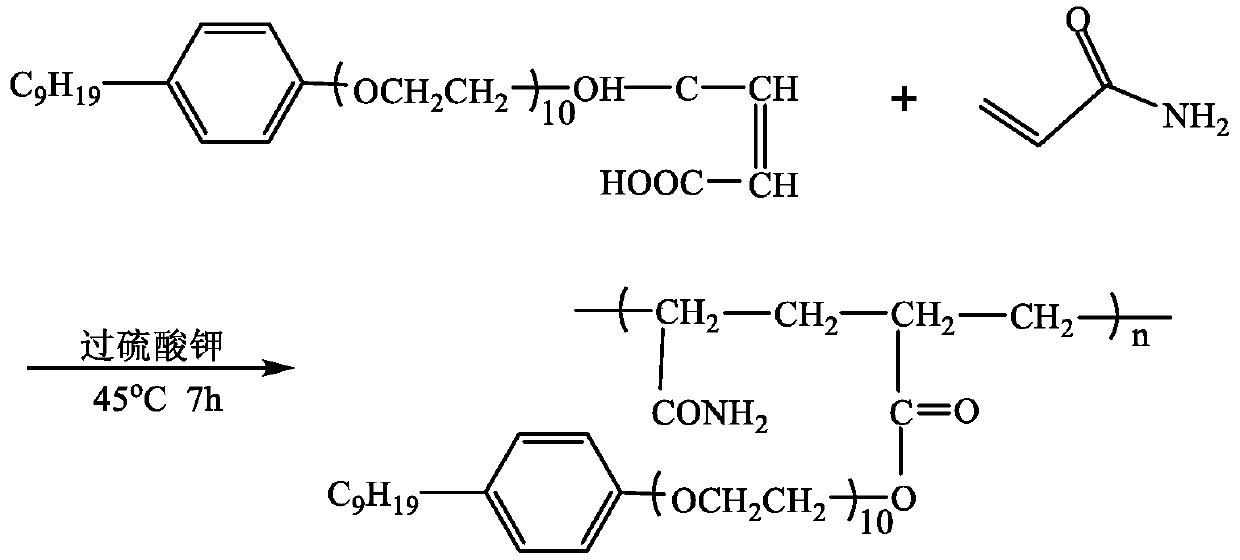

[0028] (2) Preparation of target product

[0029] Add the obtained intermediate and acrylamide into a three-necked flask with a molar ratio of 1:1, then add an appropriate amount of deionized water, stir well, and add potassium persulfate accounting for 5% by weight of the total mass of the reactants as an initiator. agent, the reaction temperature was raised to 45° C., nitrogen was passed for 20 minutes, the air in the flask was removed, and the reaction was carried out under a nitrogen atmosphere for 7 hours to obtain a visc...

Embodiment 2

[0032] (1) Synthesis of monoester intermediates

[0033] Add maleic anhydride to nonylphenol polyoxyethylene ether in a molar ratio of 1:2 into a three-necked flask equipped with a stirring device, a condensation reflux device and a thermometer, raise the reaction temperature to 100°C, and then add 3% by weight of p-toluenesulfonic acid was used as a catalyst, and the reaction was performed with magnetic stirring for 3.5 hours to obtain an intermediate.

[0034] (2) Preparation of target product

[0035] The specific preparation method is the same as step (2) in Example 1.

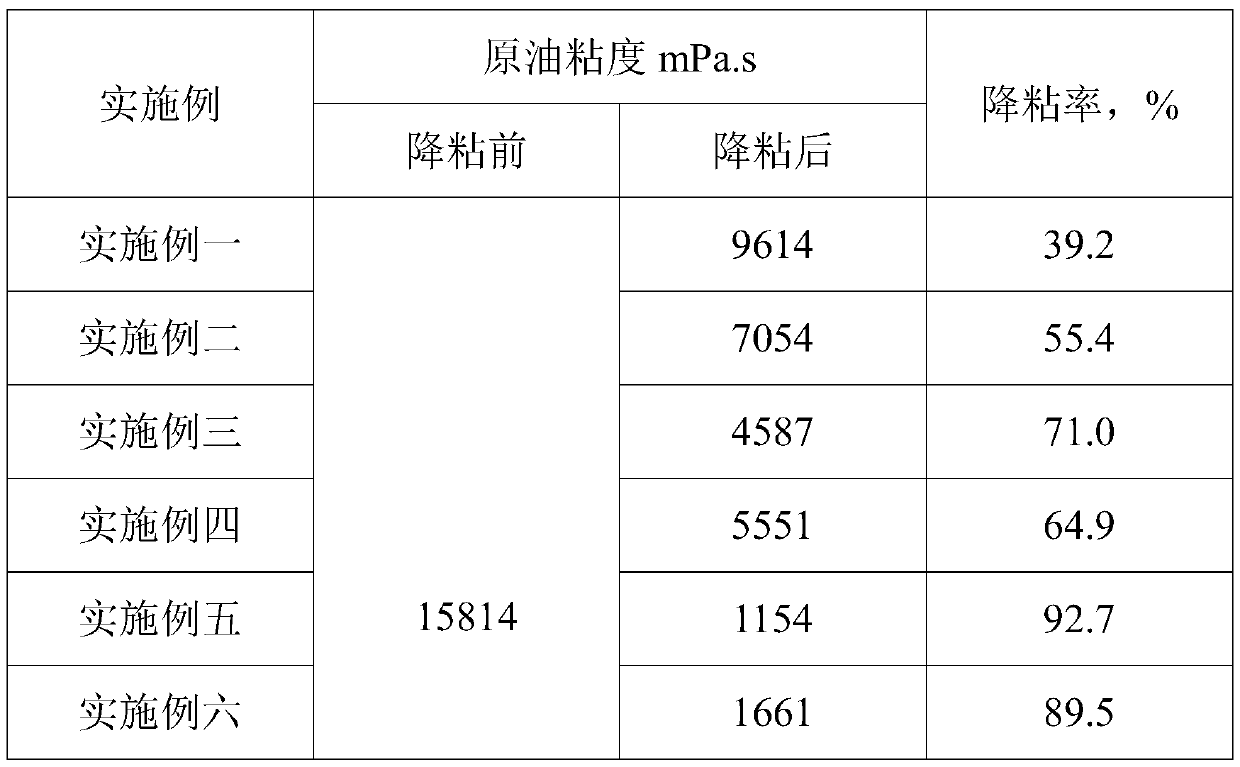

[0036] The prepared viscosity reducer was formulated into an aqueous solution with a concentration of 0.5wt%, and then the viscosity reducer aqueous solution was mixed with Tarim heavy oil at an oil-water mass ratio of 7:3, stirred evenly, and kept at 50°C for 1.5 hours, and finally Measure its viscosity at 50°C and calculate the viscosity reduction rate. The results are shown in Table 1.

Embodiment 3

[0038] (1) Synthesis of monoester intermediates

[0039] Add maleic anhydride to nonylphenol polyoxyethylene ether in a molar ratio of 2:1 into a three-necked flask equipped with a stirring device, a condensing reflux device and a thermometer, raise the reaction temperature to 100°C, and then add 3% by weight of p-toluenesulfonic acid was used as a catalyst, and the reaction was performed with magnetic stirring for 3.5 hours to obtain an intermediate.

[0040] (2) Preparation of target product

[0041] The specific preparation method is the same as step (2) in Example 1.

[0042] The prepared viscosity reducer was formulated into an aqueous solution with a concentration of 0.5wt%, and then the viscosity reducer aqueous solution was mixed with Tarim heavy oil at an oil-water mass ratio of 7:3, stirred evenly, and kept at 50°C for 1.5 hours, and finally Measure its viscosity at 50°C and calculate the viscosity reduction rate. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com