Method for preparing porous boron-doped diamond electrode with nano diamond powder as counterfeit template

A nano-diamond powder, boron-doped diamond technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of high time-consuming and cost, complex three-dimensional BDD electrode process, etc. layer capacitance, improving repeatability, and reducing the effect of equivalent resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] a. Select nano-diamond powder with a negative surface potential and a particle size of 5-10 nm and put it into deionized water for 100 minutes of ultrasonic treatment to prepare a stable diamond powder suspension with a concentration of 1 g / L for use. Select 20mm×20mm×0.5mm silicon The slices were ultrasonically cleaned with acetone, alcohol, and deionized water for 15, 15, and 10 minutes, respectively, and then dried with nitrogen for later use;

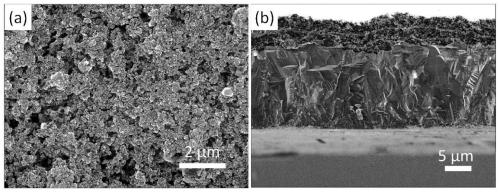

[0051] b. Drop 2ml of the diamond suspension prepared in step a onto the silicon wafer substrate to form a uniform, continuous and flat suspension film, and then evaporate the water in the suspension by heating and evaporating at a constant temperature of 60°C on a hot plate, and the nano-diamond The powder self-assembles on the silicon substrate to form a flat porous film;

[0052] c. the silicon chip substrate that contains the porous film of nano-diamond powder prepared by step b is put into a microwave plasma chemical vap...

Embodiment 2

[0055] a. Select nano-diamond powder with a negative surface potential and a particle size of 30-60 nm and put it into deionized water for 100 minutes of ultrasonic treatment to prepare a stable diamond powder suspension with a concentration of 1 g / L for use. The slices were ultrasonically cleaned with acetone, alcohol, and deionized water for 15, 15, and 10 minutes, respectively, and then dried with nitrogen for later use;

[0056] b. Drop 2ml of the diamond suspension prepared in step a onto the silicon wafer substrate to form a uniform, continuous and flat suspension film, and then evaporate the water in the suspension by heating and evaporating at a constant temperature of 60°C on a hot plate, and the nano-diamond The powder self-assembles on the silicon substrate to form a flat porous film;

[0057] c. the silicon chip substrate that contains the porous film of nano-diamond powder prepared by step b is put into a microwave plasma chemical vapor deposition chamber and evac...

Embodiment 3

[0060] a. Select nano-diamond powder with a negative surface potential and a particle size of 5-10 nm and put it into deionized water for 100 minutes of ultrasonic treatment to prepare a stable diamond powder suspension with a concentration of 1 g / L for use. Silicon wafers were ultrasonically cleaned with acetone, alcohol, and deionized water for 15, 15, and 10 minutes, respectively, and then dried with nitrogen for later use;

[0061] b. Drop 2ml of the diamond suspension prepared in step a onto the silicon wafer substrate to form a uniform, continuous and smooth suspension film, and then evaporate the water in the suspension by heating and evaporating at a constant temperature of 65°C on a hot plate, and the nano-diamond The powder self-assembles on the silicon substrate to form a flat porous film;

[0062] c. the silicon chip substrate that contains the porous film of nano-diamond powder prepared by step b is put into a microwave plasma chemical vapor deposition chamber and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com