Dietary-fiber-rich nutritional fine dried noodle and preparing method thereof

A technology of dietary fiber and dried noodles, applied in the field of dried noodles, can solve the problems of inability to meet the needs of various nutrient elements, excessive absorption on the surface of dried noodles, single nutrient components of dried noodles, etc., to prevent cardiovascular diseases, improve taste and chewiness, The effect of improving chewiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

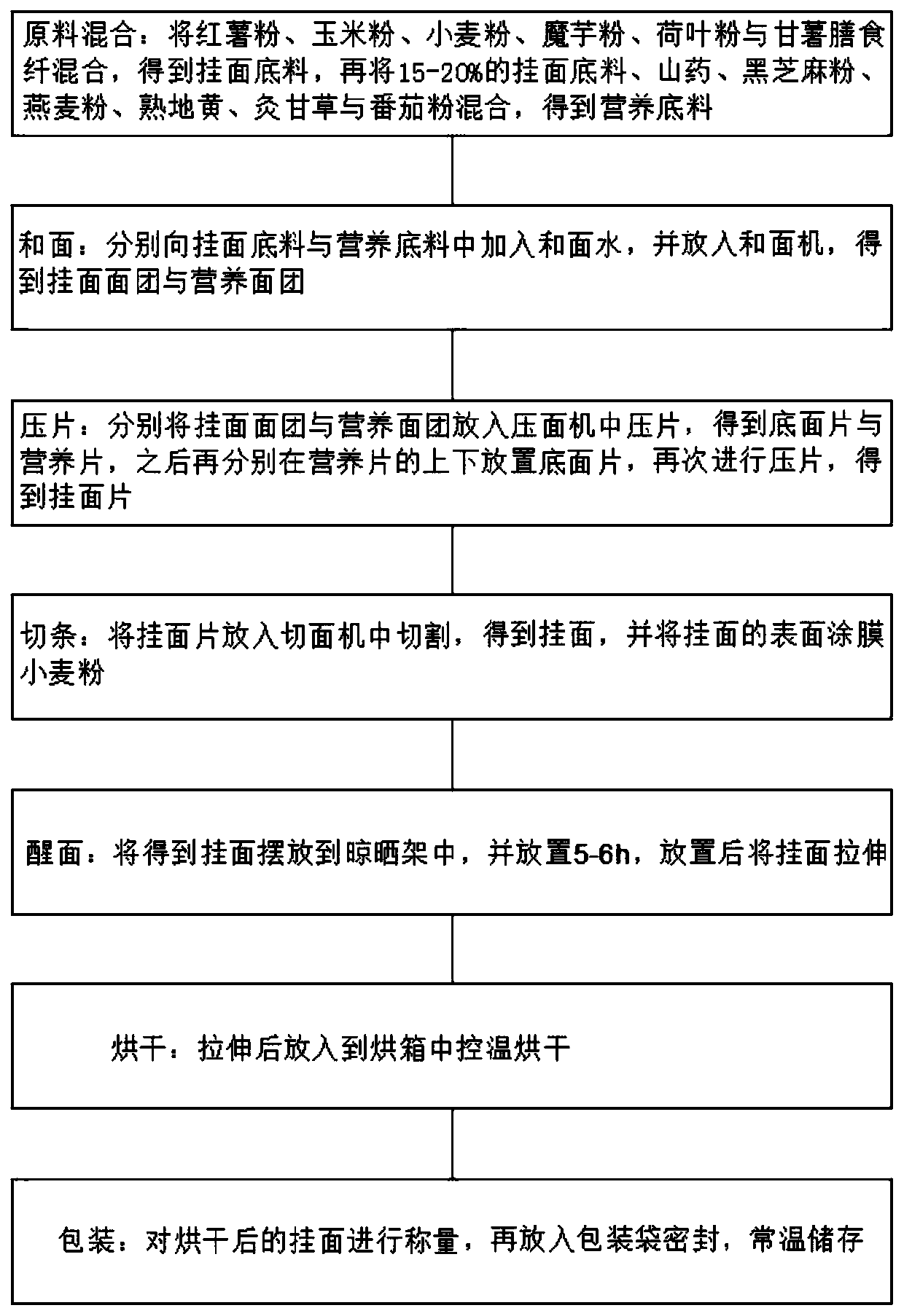

[0072] Such as figure 1 As shown, a nutritious dried noodle rich in dietary fiber is composed of the following raw materials in weight ratio: 2 parts of peach kernel, 23 parts of sweet potato flour, 22 parts of corn flour, 38 parts of wheat flour, 13 parts of eggs, 18 parts of konjac flour, and salt 3 portions, 900 portions of water, 13 portions of lotus leaf powder, 30 portions of sweet potato dietary fiber, 110 portions of beef bone soup, 28 portions of apple juice, 6 portions of yam, 3 portions of celery juice, 36 portions of black sesame powder, 19 portions of oatmeal powder, 12 parts of Rehmannia glutinosa, 11 parts of moxibustion licorice, 24 parts of honey, 23 parts of tomato powder.

[0073] A method for preparing nutritional dried noodles rich in dietary fiber, the specific steps are as follows:

[0074] (1) Mixing of raw materials: mix sweet potato flour, corn flour, wheat flour, konjac flour, lotus leaf powder and sweet potato dietary fiber to obtain the noodle base mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com