Preparation method and application of carbon-based Janus membrane

A carbon-based, solution-based technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as high energy consumption, expensive equipment, and inconvenient maintenance, and achieve good reusability, easy portability, and simple methods quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] Specific embodiment one: a kind of preparation method of carbon-based Janus membrane is finished according to the following steps:

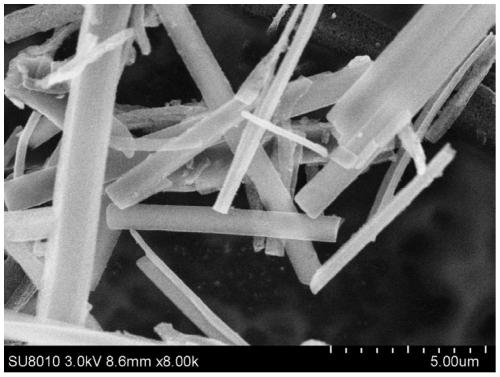

[0037] 1. Preparation of MgCO 3 fiber:

[0038] NaCO with a concentration of 0.5mol / L~1.5mol / L 3 Add the solution dropwise to MgCl with a concentration of 1mol / L~2mol / L 2 ·6H 2 O solution, dried after stirring to obtain MgCO 3 fiber;

[0039] The NaCO concentration described in step 1 is 0.5mol / L~1.5mol / L 3 Solution and MgCl with concentration of 1mol / L~2mol / L 2 ·6H 2 The volume ratio of O solution is (20~3000):(20~3000);

[0040] 2. Preparation of graphene fibers:

[0041] ①. First, evenly spread MgCO in the quartz boat 3 fiber, which will then be coated with MgCO 3 The fiber quartz boat is transferred to the horizontal CVD furnace, and then argon gas is introduced into the horizontal CVD furnace, and the temperature of the horizontal CVD furnace is raised from room temperature at a rate of 4°C / min to 15°C / min under the protect...

specific Embodiment approach 2

[0056] Embodiment 2: This embodiment differs from Embodiment 1 in that: the stirring speed in step 1 is 50r / min-400r / min, and the stirring time is 0.5h-1.5h. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the drying temperature in step 1 is 35°C-65°C, and the drying time is 0.5h-3.5h. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap