Dissimilar metal welding method for low-carbon steel and cast iron

A technology of dissimilar metals and welding methods, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of increasing welding energy input, unfavorable welding deformation, increasing welding cost, etc., to reduce the tendency of weld cracking, Improve the effect of weld forming factor and weld width increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

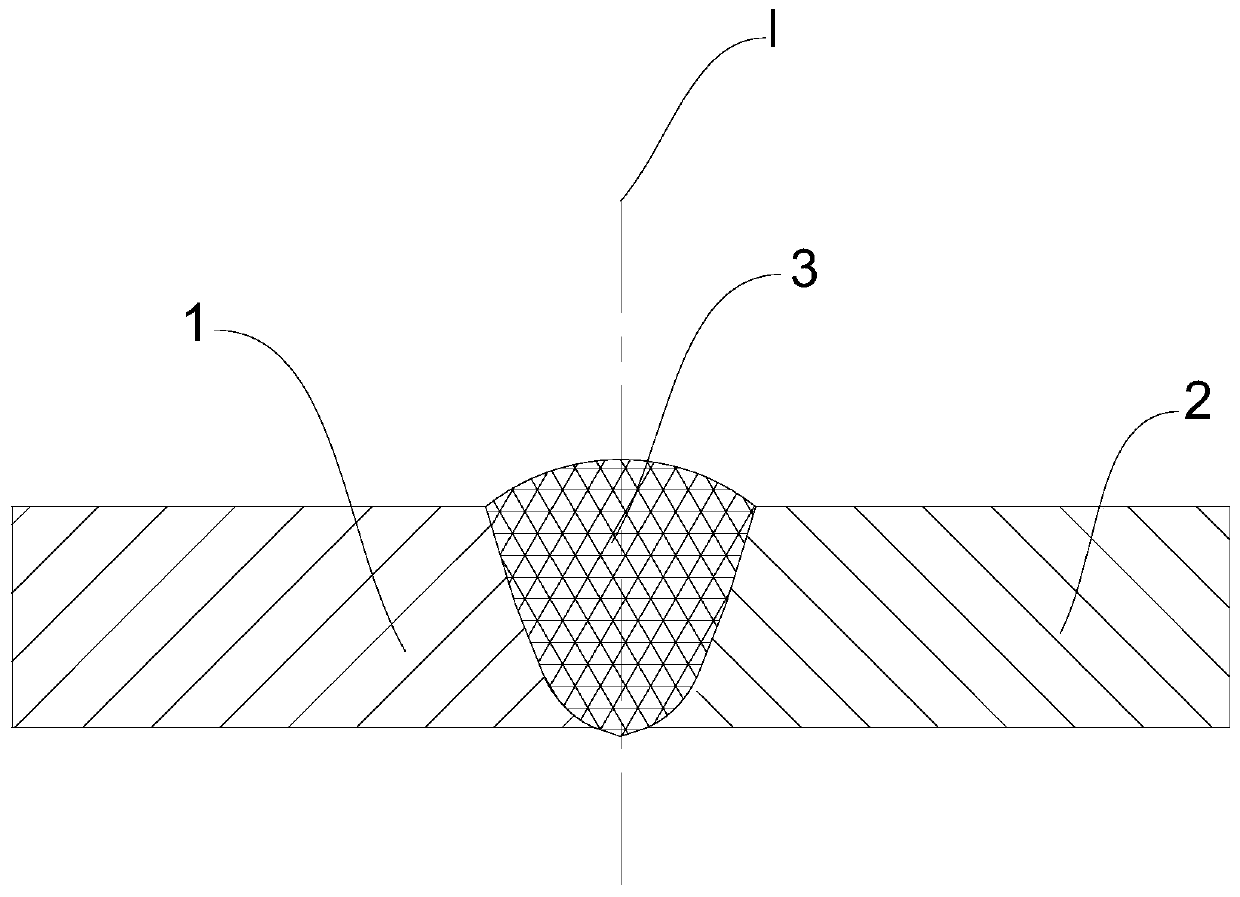

[0035] A method for laser butt welding of dissimilar metals between low carbon steel and cast iron, comprising the steps of:

[0036] S1. Prepare the base metal: the carbon content of low carbon steel 1 is 0.07wt%, the carbon content of cast iron 2 is 2wt%, and the thickness of low carbon steel 1 and cast iron 2 is 1mm;

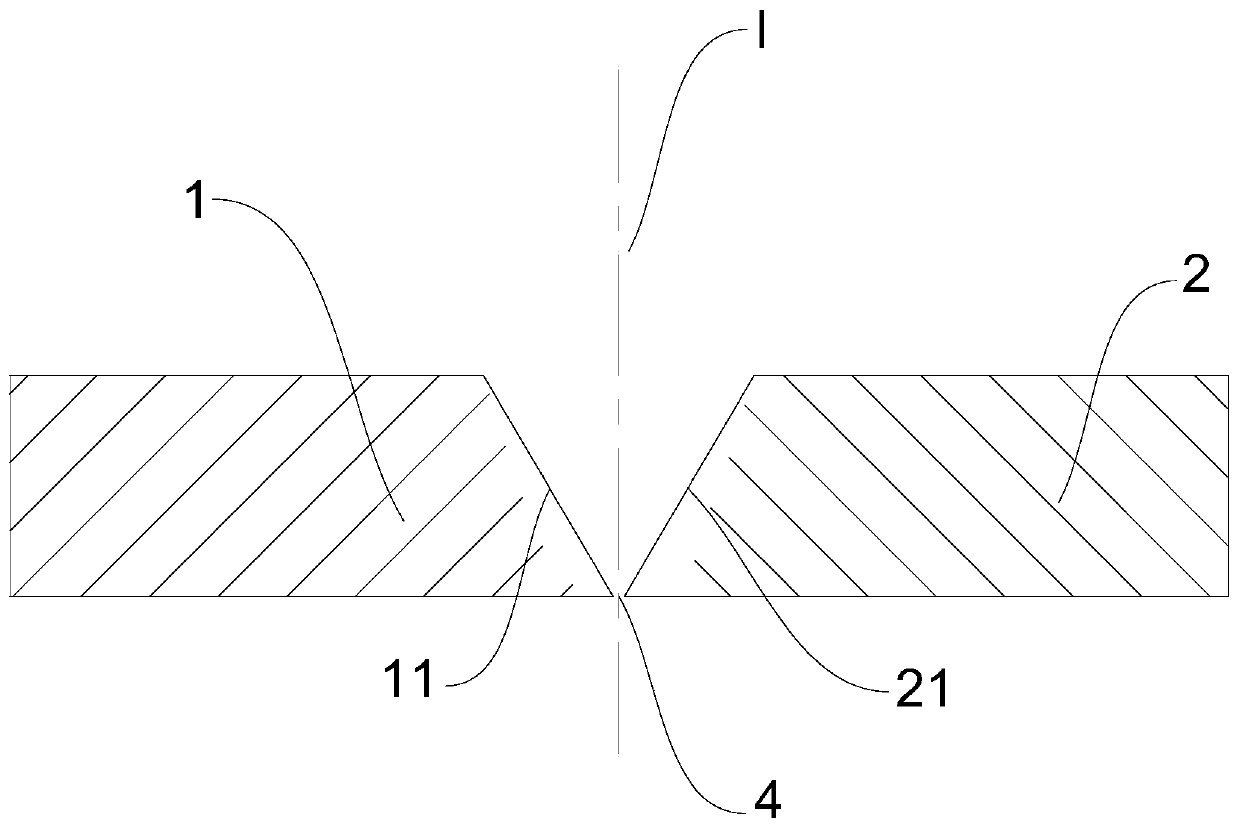

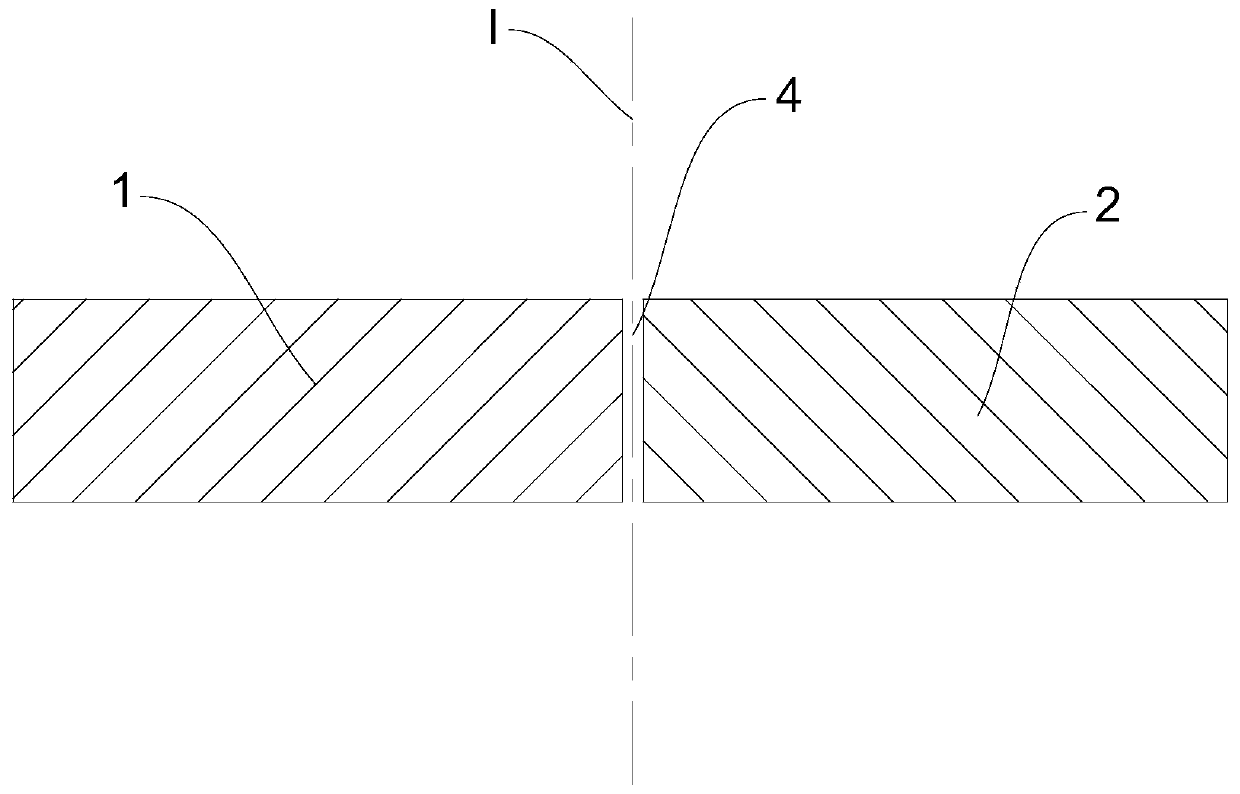

[0037] S2. Base metal surface cleaning and assembly: clean the base metal, remove oxides and oil stains on the surface, that is, clean oil stains, rust, etc. in the area to be welded, and assemble the surface-cleaned low-carbon steel 1 to be welded and cast iron 2 horizontally, Fix it with a tooling fixture to form the part to be welded. The assembly gap 4 of the butt joint between the low carbon steel 1 and the cast iron 2 is 0mm;

[0038] S3. Welding process: The connection of dissimilar metals between low carbon steel 1 and cast iron 2 adopts swing and offset self-fluxing welding process to weld the workpiece to be welded. The main welding parameters are: ...

Embodiment 2

[0042] A method for laser butt welding of dissimilar metals between low carbon steel and cast iron, comprising the steps of:

[0043] S1. Prepare the base metal: the carbon content of low carbon steel 1 is 0.3wt%, the carbon content of cast iron 2 is 2.5wt%, and the thickness of low carbon steel 1 and cast iron 2 are both 5mm;

[0044] S2. Base metal surface cleaning and assembly: clean the base metal, remove oxides and oil stains on the surface, that is, clean oil stains, rust, etc. in the area to be welded, and assemble the surface-cleaned low-carbon steel 1 to be welded and cast iron 2 horizontally, Fix it with a tooling fixture to form the part to be welded. The assembly gap 4 of the butt joint between the low carbon steel 1 and the cast iron 2 is 0.2mm;

[0045]S3. Welding process: The connection of dissimilar metals between low carbon steel 1 and cast iron 2 adopts swing and offset self-fluxing welding process to weld the workpiece to be welded. The main welding paramete...

Embodiment 3

[0049] A method for laser butt welding of dissimilar metals between low carbon steel and cast iron, comprising the steps of:

[0050] S1. Prepare base metal: low carbon steel 1 with a carbon content of 0.6wt%, low carbon steel 1 with a thickness of 8mm, cast iron 2 with a carbon content of 4wt%, and cast iron 2 with a thickness of 10mm;

[0051] S2. Base metal surface cleaning and assembly: clean the base metal, remove oxides and oil stains on the surface, that is, clean oil stains, rust, etc. in the area to be welded, and assemble the surface-cleaned low-carbon steel 1 to be welded and cast iron 2 horizontally, Fix it with a fixture to form the part to be welded. The assembly gap 4 of the butt joint between the low carbon steel 1 and the cast iron 2 is 0.5mm;

[0052] S3. Welding process: the connection of dissimilar metals between low carbon steel 1 and cast iron 2 adopts swing and offset self-fluxing welding process to weld the workpiece to be welded. The main welding param...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com