MBR membrane pool structure and transmission system enabling MBR membrane assembly to do reciprocating movement

A technology of membrane modules and membrane pools, which is applied in the field of transmission systems, can solve problems such as labor costs and time, increased water treatment costs, hair clogging, etc., and achieve the effects of improved operational stability, extended service life, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

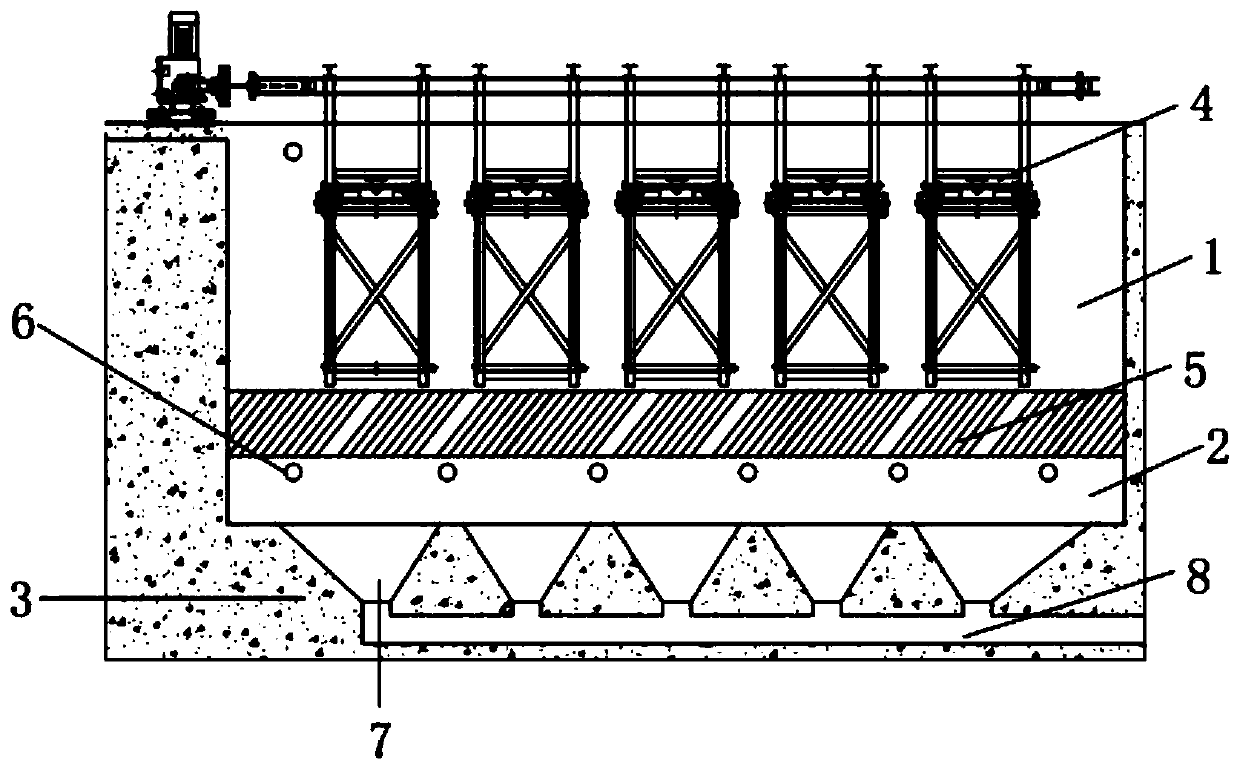

[0053] The embodiment of the present invention provides a MBR membrane tank structure with controllable sludge stratification. The MBR membrane tank structure is based on hydraulics and sludge sedimentation principles, through clever calculations and designs, and makes full use of the sludge stratification in the membrane tank. In the longitudinal direction of the membrane tank, the upper low sludge concentration zone, the middle separation zone and the lower high sludge concentration zone are formed in the longitudinal direction of the membrane tank, and the membrane module system is in the upper low sludge concentration zone, which is beneficial to reduce membrane pollution Speed, significantly enhance the effect of membrane pollution control, increase the long-term stability of membrane system operation; and make the return pipeline arranged in the lower layer of high sludge concentration area, in the case of reaching the same return effect, the return ratio can be reduced, an...

Embodiment 2

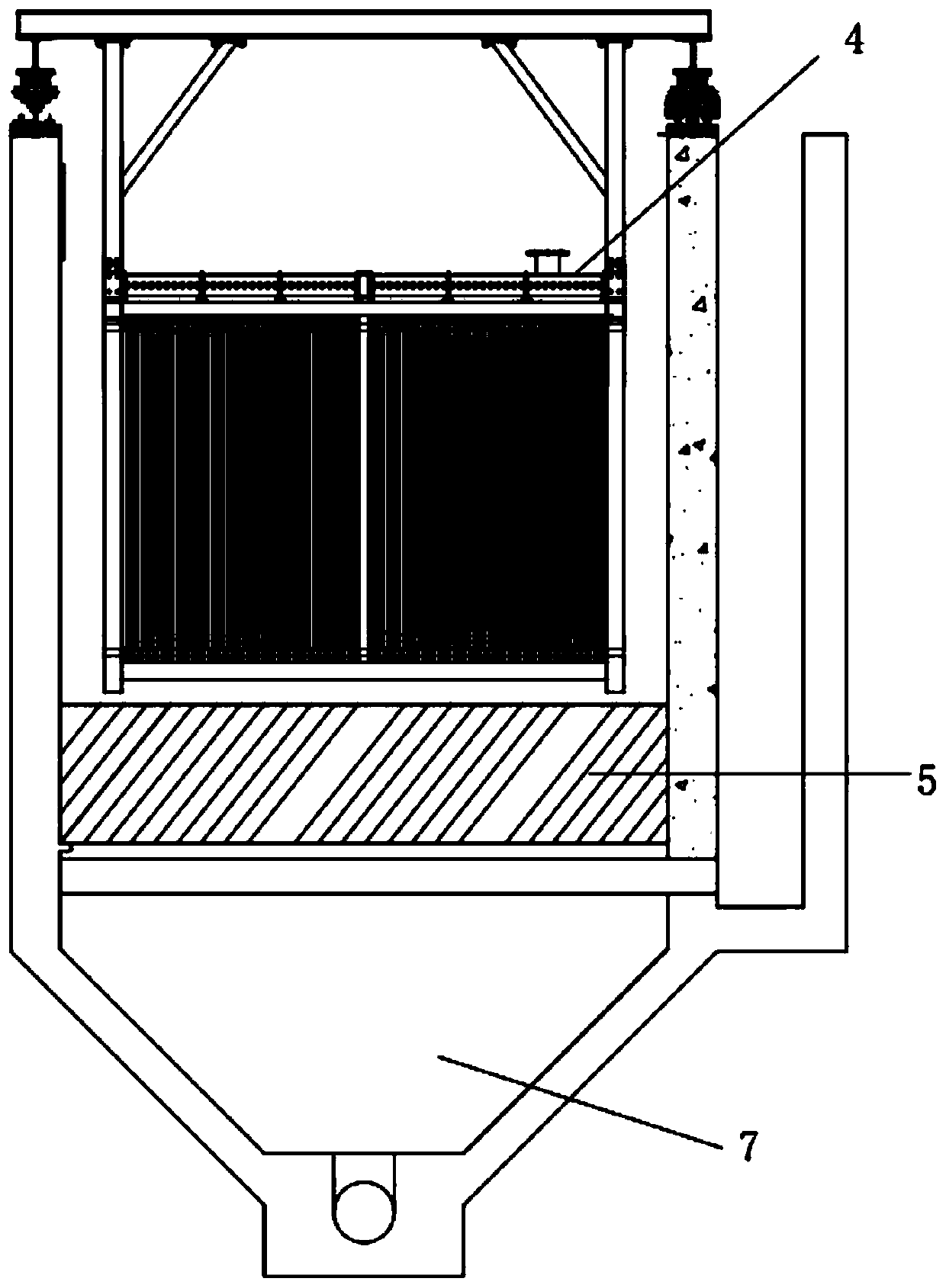

[0078] This embodiment provides a transmission system for reciprocating the MBR membrane module. The system includes the MBR membrane tank structure of the first embodiment and a transmission device based on dual-arm output. The transmission device is arranged on the upper part of the MBR membrane tank structure. The MBR membrane module in the MBR membrane pool structure is supported by the carriage in the transmission device, and the MBR membrane module is driven to reciprocate through the track, rolling wheel and variable frequency motor in the transmission device. The movement form can be horizontal reciprocating movement, reciprocating swing, reciprocating curve movement and so on.

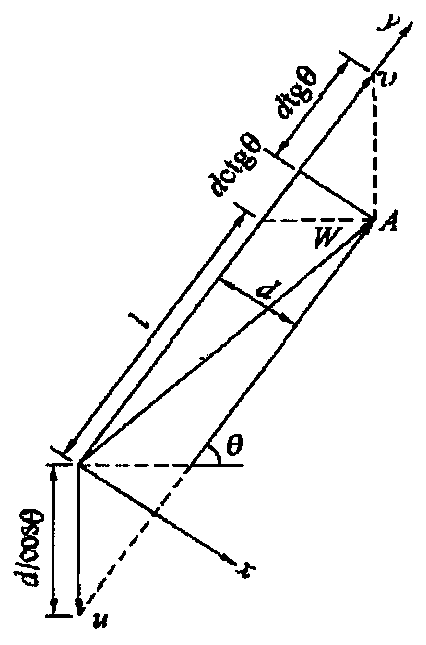

[0079] The structure of the transmission device for the double-arm output that causes the membrane module to reciprocate is as follows Figure 4 with Figure 5 As shown, the transmission device includes a speed reducer 16, a frequency conversion motor 17, a carriage 21, a transmission mechanism 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com