Temperable LOW-E glass and preparation method thereof

A glass and glass matrix technology, applied in the field of temperable LOW-E glass and its preparation, can solve the problems of large color changes and achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

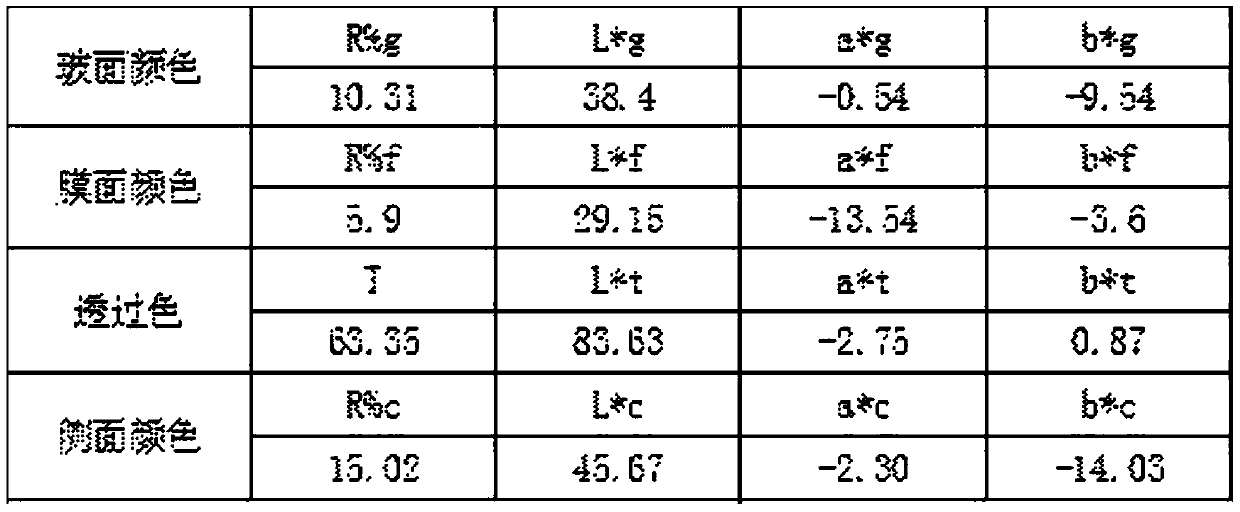

Embodiment 1

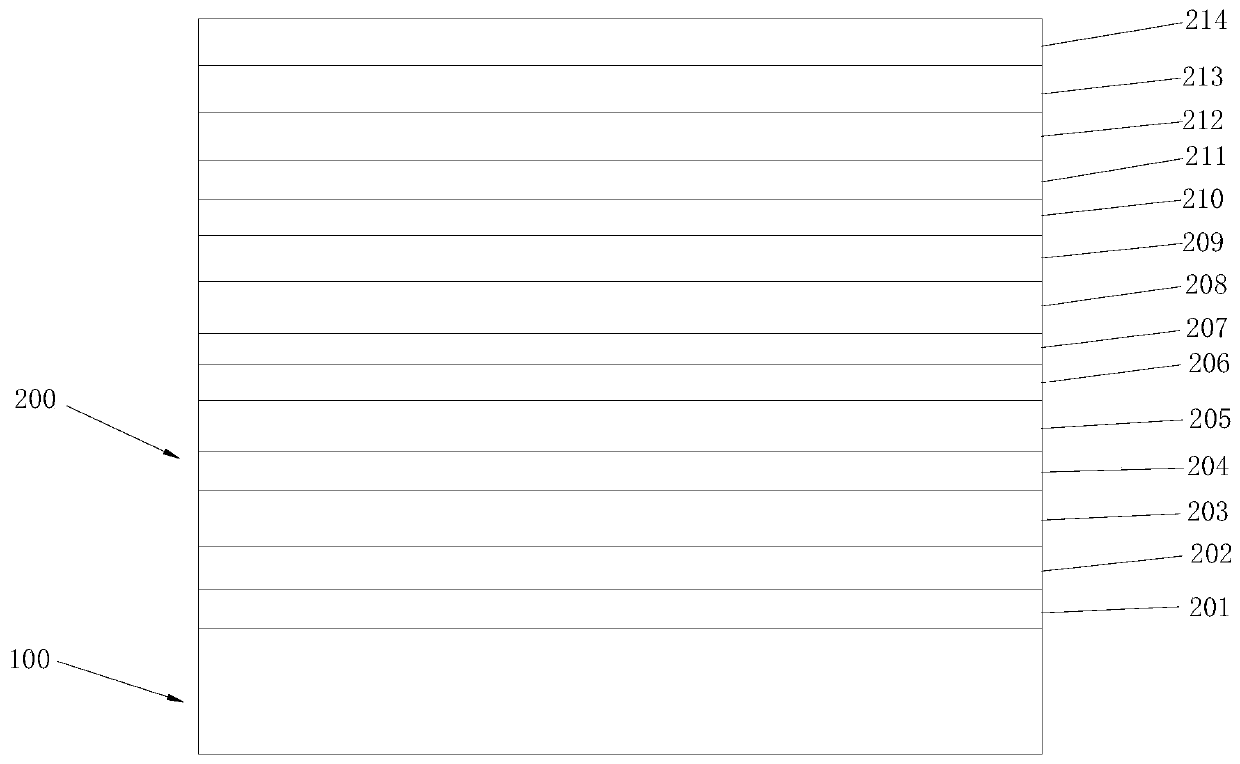

[0033] The structure of the composite film layer 200 on the surface of the glass substrate 100 in this example is: SiNx layer / TiOx layer / ZnOx layer / Ag layer / NiCr layer / AZO layer / SiNx layer / NiCr layer / SiNx layer / ZnOx layer / Ag layer / NiCr layer / AZO layer / SiNx layer.

[0034] The thickness of each film layer in the composite film layer 200 is 34.2nm / 9.8nm / 15.2nm / 9.2nm / 1.8nm / 8.9nm / 29.3nm / 1.1nm / 33.7nm / 15.0nm / 10.1nm / 1.3nm / 9.2nm nm / 27.4nm.

[0035] The preparation method of temperable LOW-E glass in this embodiment is as follows:

[0036] 1. The first dielectric layer 201 is plated on the glass substrate 100 by magnetron sputtering process: under the control of an intermediate frequency AC power supply, the silicon target is sputtered in a mixed atmosphere of argon and nitrogen (Ar:N2=9:7) Spray deposition, the first dielectric layer with a film thickness of 34.2nm is a SiNx layer;

[0037] 2. Coating the transition layer 202 on the first dielectric layer by magnetron sputtering: U...

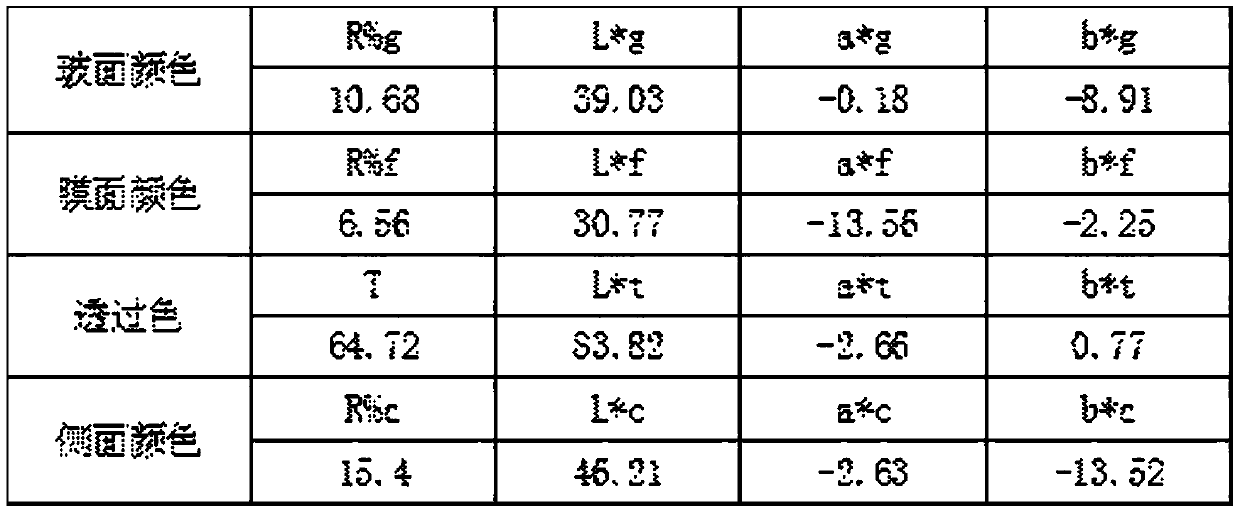

Embodiment 2

[0060] The structure of the composite film layer 200 on the surface of the glass substrate 100 in this example is: SiNx layer / TiOx layer / ZnOx layer / Ag layer / NiCr layer / AZO layer / SiNx layer / NiCr layer / SiNx layer / ZnOx layer / Ag layer / NiCr layer / AZO layer / SiNxOy layer.

[0061] The thickness of each film layer in the composite film layer 200 is 29.7nm / 4.6nm / 14.8nm / 7.1nm / 1.8nm / 8.8nm / 30.8nm / 1.3nm / 34.3nm / 15.9nm / 9.8nm / 1.3nm / 9.3nm nm / 25.6nm.

[0062] The preparation method of temperable LOW-E glass in this embodiment is as follows:

[0063] 1. The first dielectric layer 201 is plated on the glass substrate 100 by magnetron sputtering process: under the control of an intermediate frequency AC power supply, the silicon target is sputtered in a mixed atmosphere of argon and nitrogen (Ar:N2=9:7) Spray deposition, depositing a first dielectric layer 201 (SiNx layer) with a film thickness of 29.7 nm;

[0064] 2. Using the magnetron sputtering process, the transition layer 202 is plated on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com