Microbial reinforcing non-cohesive soil curing agent and reinforcing method thereof

A non-cohesive soil and microbial technology, applied in chemical instruments and methods, soil protection, building construction, etc., can solve problems such as hindering application, increase saturation, reduce the generation of reinforcement by-product ammonia, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] 1. Preparatory work before construction:

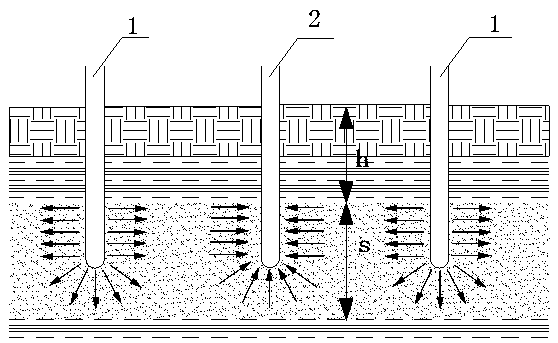

[0073] 1. Obtain the depth h=3m from the upper surface of the non-cohesive soil layer to be reinforced from the ground surface and the thickness s=5m of the non-cohesive soil layer through investigation;

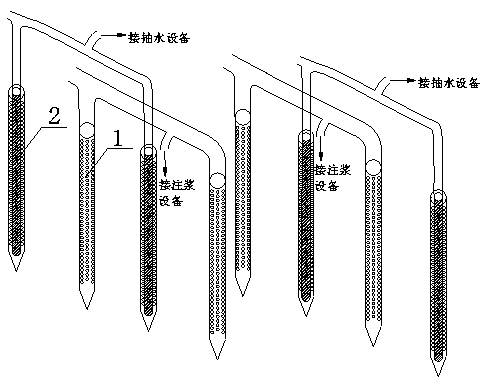

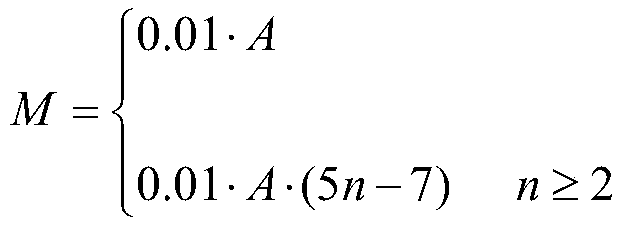

[0074] 2. Drill a number of wells vertically downward on the surface of the non-cohesive soil layer to be reinforced. All the wells are evenly distributed in a matrix at a distance of 1.5m. All the wells are divided into grouting wells and pumping wells. They are all pumping wells, and the surroundings of the pumping wells are all grouting wells; and a steel flower tube with a diameter of 60mm and a wall thickness of 5mm is inserted into each well, and the length l of the steel flower tube inserted into the ground is 7m; the vertical error of the drilling construction plane is not greater than 80cm;

[0075] 3. A grouting pipe and a pumping pipe are respectively installed in the grouting well and the pumping well. One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com