Reinforced-steel magnesium alloy passenger car frame and design method thereof

A magnesium alloy and passenger car technology, applied in the frame field, can solve the problems of limited energy density of power battery packs, difficulty in making breakthroughs in cruising range and battery efficiency, etc., achieve good shock absorption and noise reduction characteristics, and improve operation The effect of safety reliability and high damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

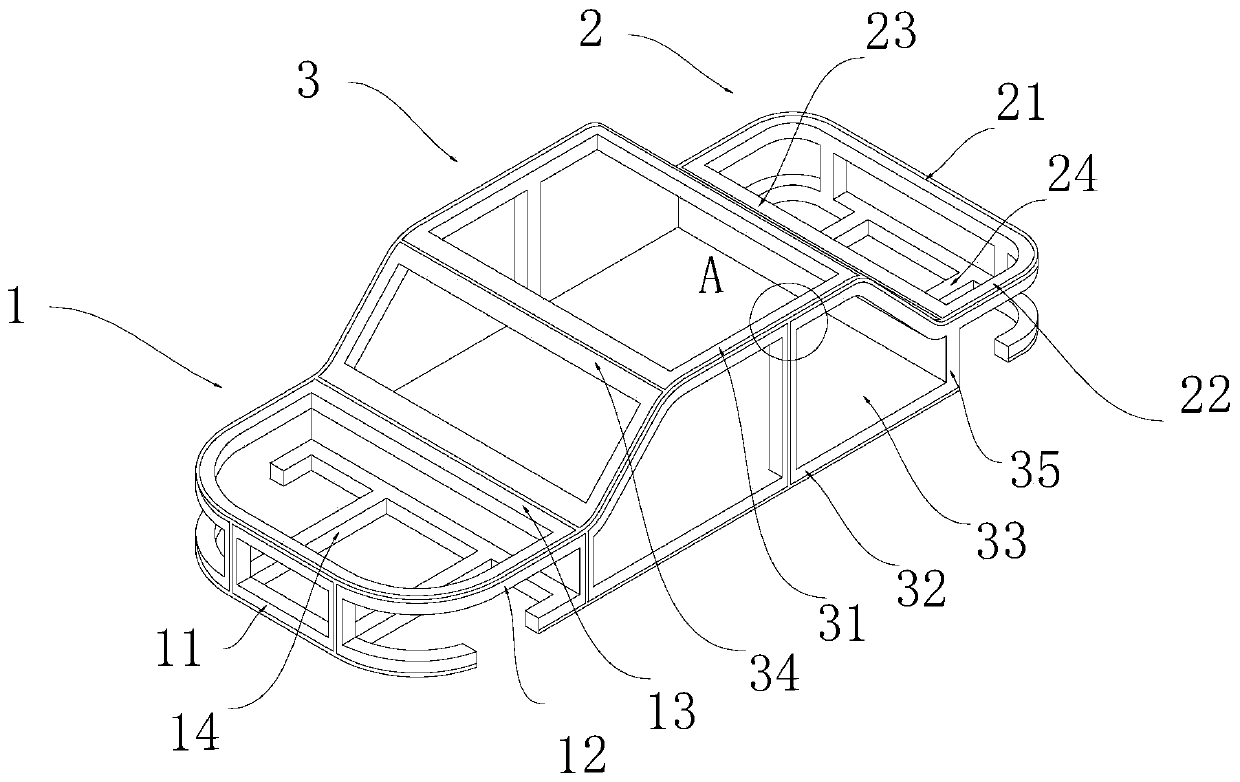

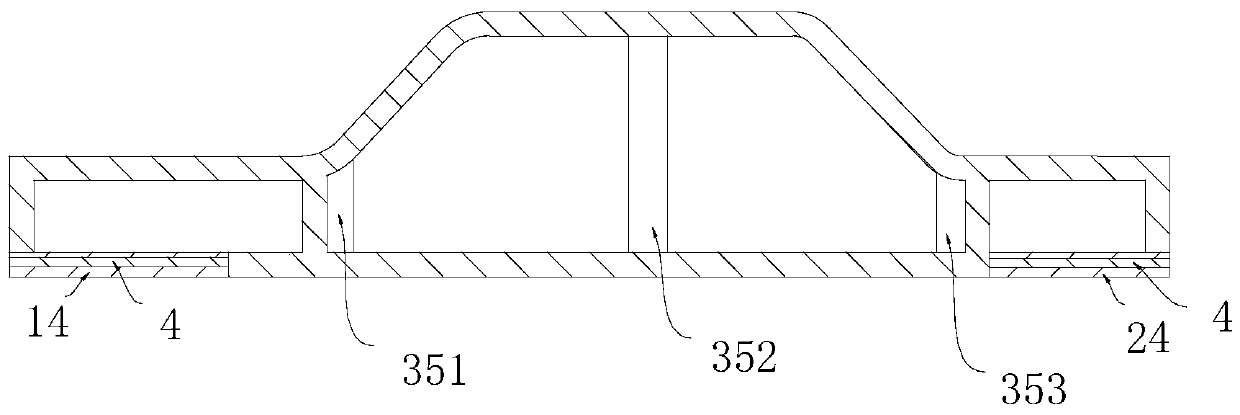

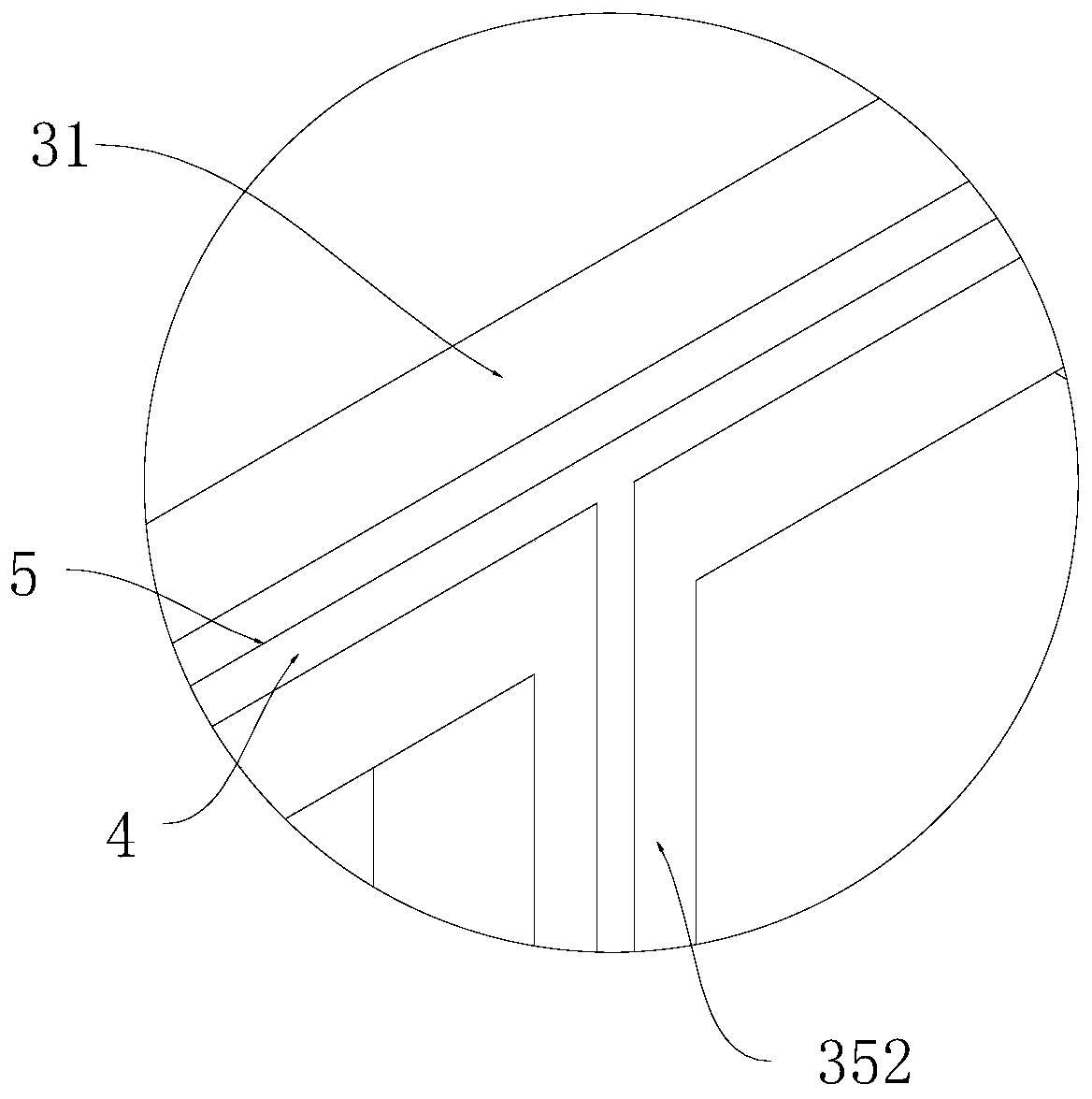

[0029] see Figure 1 to Figure 3In the present invention, the vehicle frame includes a front beam 1, a rear beam 2 and a connecting beam 3 arranged between the front beam 1 and the rear beam 2, the front beam 1 and the rear beam 2 are arranged symmetrically with respect to the connecting beam 3 and the front beam 1, the rear beam 2 and the connection beams The materials used in the beam 3 are all magnesium alloys. The front beam 1 includes a plurality of front anti-collision beams 11 arranged in parallel, a front finger beam 12 arranged at both ends of the front anti-collision beam 11, and a front finger beam 12 arranged between the front finger beam 12 and the connecting beam 3. The front crossbeam 13 and the front longitudinal beam 14 arranged between the front anti-collision beam 11 and the connecting beam 3; the connecting beam 3 includes a plurality of roof longitudinal beams 31 arranged between the front beam 1 and the rear beam 2, and the Multiple groups of sill beams 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com