Method for preparing basic copper sulfate two-dimensional nano-sheets through rapid precipitation

A two-dimensional nano, copper sulfate technology, applied in copper sulfate, nanotechnology, nanotechnology and other directions, to achieve the effect of simple operation, novel appearance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The invention provides a method for rapidly precipitating two-dimensional nanosheets of basic copper sulfate. The method takes copper sulfate and ammonia water as raw materials, and synthesizes it by liquid phase precipitation method, and its specific operation steps are as follows:

[0020] Step 1, at 25°C, 700g of 0.3% copper sulfate and 300g of 0.09% ammonia were dissolved in water and kept stirring for 10 minutes;

[0021] Step 2, using a high-speed centrifuge to separate the mixed material obtained in step 1 at 4000r / min for 5 minutes;

[0022] Step 3, the light blue precipitate of gained is washed 3 times with 96% ethanol solution;

[0023] Step 4, drying the material obtained in Step 3 at 60° C. for 10 hours to obtain basic copper sulfate two-dimensional nanosheets.

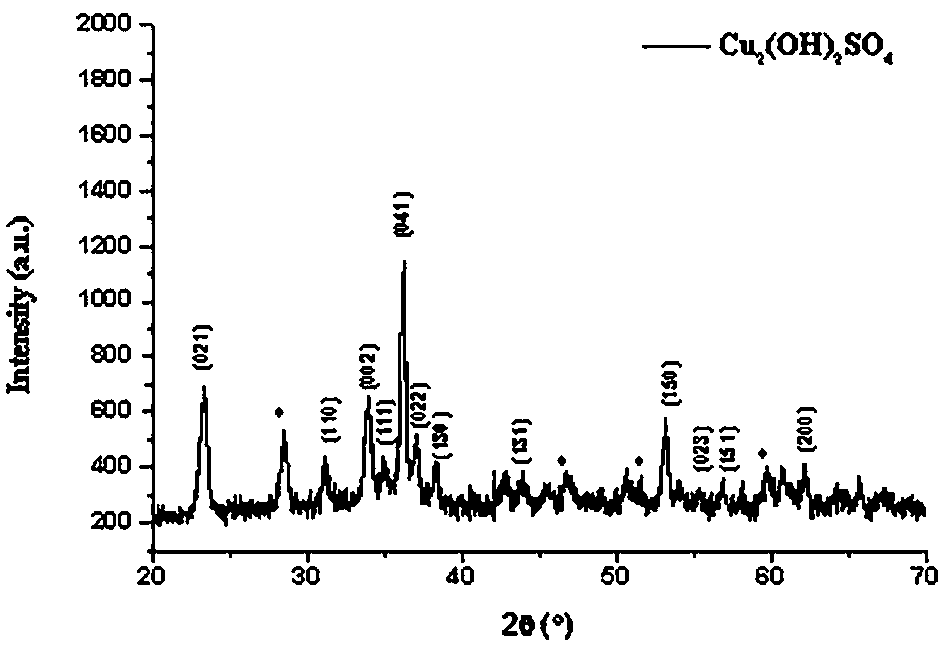

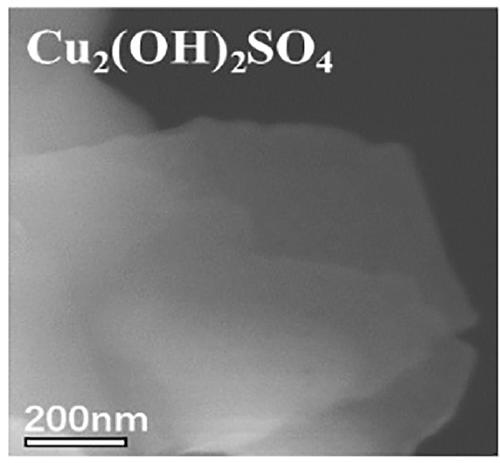

[0024] XRD results such as figure 1 The product structure is basic copper sulfate, the appearance is as follows figure 2 As shown, it is a nano-scale sheet structure, and the width of the nano-...

Embodiment 2

[0026] The invention provides a method for rapidly precipitating two-dimensional nanosheets of basic copper sulfate. The method takes copper sulfate and ammonia water as raw materials, and synthesizes it by liquid phase precipitation method, and its specific operation steps are as follows:

[0027] Step 1: Dissolve 750g of 0.5% copper sulfate and 250g of 0.10% ammonia water at 25°C in water, and keep stirring for 10 minutes;

[0028] Step 2, using a high-speed centrifuge to separate the mixed material obtained in step 1 at 4000 r / min for 5 minutes;

[0029] Step 3, the light blue precipitate of gained is washed 3 times with 96% ethanol solution;

[0030] Step 4, drying the material obtained in Step 3 at 60° C. for 10 hours to obtain basic copper sulfate two-dimensional nanosheets.

Embodiment 3

[0032] The invention provides a method for rapidly precipitating two-dimensional nanosheets of basic copper sulfate. The method takes copper sulfate and ammonia water as raw materials, and synthesizes it by liquid phase precipitation method, and its specific operation steps are as follows:

[0033] Step 1: Dissolve 800g of 0.8% copper sulfate and 200g of 0.11% ammonia in water at 25°C, and keep stirring for 10 minutes;

[0034] Step 2, using a high-speed centrifuge to separate the mixed material obtained in step 1 at 4000r / min for 5 minutes;

[0035] Step 3, the light blue precipitate of gained is washed 3 times with 96% ethanol solution;

[0036] Step 4, drying the material obtained in Step 3 at 60° C. for 10 hours to obtain basic copper sulfate two-dimensional nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap