Tandem anaerobic ammonia oxidation process for room-temperature denitrification of high-ammonia wastewater

An anaerobic ammonium oxidation, series-type technology, applied in the field of series-type anaerobic ammonium oxidation process, can solve the problems of unfavorable industrial application and high treatment cost, and achieve the advantages of easy large-scale promotion, low treatment cost and increased total nitrogen removal load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

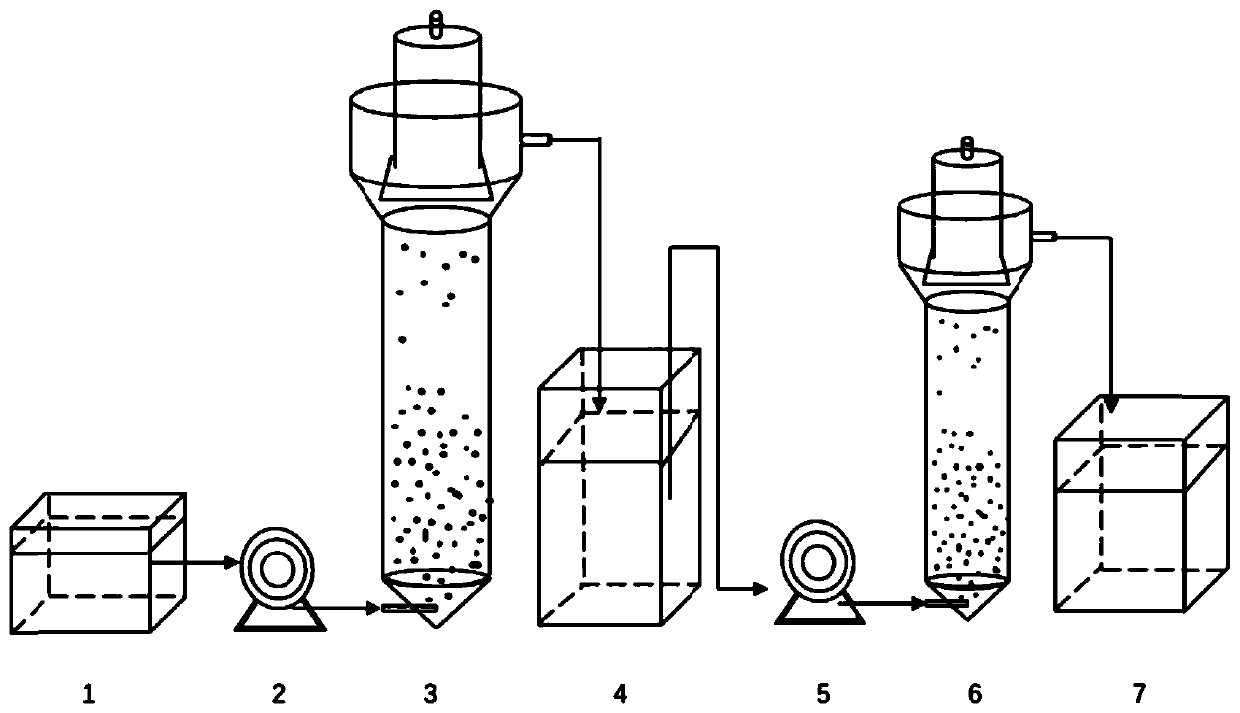

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. For the experimental methods without specific conditions indicated in the following examples, the conventional conditions or the conditions suggested by the manufacturer are usually followed.

[0042] Sludge inoculation was carried out in two upflow anaerobic sludge bed reactors with similar shapes and different volumes. Reactor A had a volume of 2L and was inoculated with 1.1L of anammox granular sludge; Reactor B had a volume of 0.9L. Inoculate 0.5 L of anammox granular sludge. The inoculated granular sludge was first eluted three times with inorganic salt solution and tap water to remove the residual matrix.

[0043] The two reactors are independently started and the load is increased, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com