A kind of clean production method of tetrabenzylthiuram disulfide

A technology of tetrabenzylthiuram disulfide and production method, applied in directions such as organic chemistry, can solve problems such as recycling, increase production cost of waste water treatment and environmental pollution, and achieve reduction in production cost and pale yellow appearance , The effect of reducing the hidden danger of process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

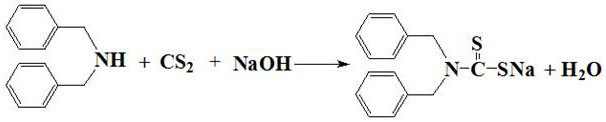

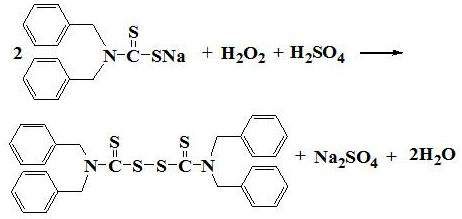

Method used

Image

Examples

Embodiment 1

[0032] 1. Weigh each raw material: 100g of dibenzylamine, 22.3g of sodium hydroxide, 42.5g of carbon disulfide, 69.5g of 50% sulfuric acid, 47.9g of 27% hydrogen peroxide solution, and 600g of water;

[0033] 2. Add dibenzylamine and sodium hydroxide into 200g of water according to the proportion, add carbon disulfide dropwise at a rate of 9ml / min at room temperature, cool down to 0°C after dropping, filter and separate the precipitated solid;

[0034] 3. Put the obtained solid into a new reaction vessel, add 360g of water to dissolve it, and then lower the temperature to 10°C.

[0035] 4. Add 50wt% sulfuric acid dropwise to the reaction vessel in step 3 at a rate of 25ml / min, control the reaction temperature during and after the dropwise addition to be 10°C, and then add 27wt% hydrogen peroxide solution at a rate of 1ml / min Continue to add dropwise into the reaction vessel at a speed of 1 min, and control the reaction temperature during the dropwise addition to 10°C. After dr...

Embodiment 2

[0038] 1. Weigh each raw material: 100g of dibenzylamine, 20.3g of sodium hydroxide, 38.6g of carbon disulfide, 49.7g of 50% sulfuric acid, 31.9g of 27% hydrogen peroxide solution;

[0039] 2. Add dibenzylamine and sodium hydroxide to the filtrate of step 2 in Example 1 according to the proportioning ratio. If the filtrate is less than 200g, make up with pure water. Add carbon disulfide dropwise at a rate of 9ml / min at normal temperature, drop After cooling down to 0°C, filter and separate the precipitated solid;

[0040] 3. Put the obtained solid into a new reaction vessel, add the filtrate from Step 4 in Example 1, make up for the filtrate less than 360g with pure water, stir to dissolve, and then lower the temperature to 10°C.

[0041] 4. Add 50wt% sulfuric acid dropwise to the reaction vessel in step 3 at a rate of 25ml / min, control the reaction temperature during and after the dropwise addition to be 10°C, and then add 27wt% hydrogen peroxide solution at a rate of 1ml / min...

Embodiment 3

[0043] 1. Weigh each raw material: 100g of dibenzylamine, 20.3g of sodium hydroxide, 38.6g of carbon disulfide, 49.7g of 50% sulfuric acid, 31.9g of 27% hydrogen peroxide solution;

[0044] 2. Add dibenzylamine and sodium hydroxide into the filtrate of step 2 in Example 2 according to the proportioning ratio. If the filtrate is less than 200g, make up with pure water. Add carbon disulfide dropwise at a rate of 10ml / min at normal temperature, drop After cooling down to 0°C, filter and separate the precipitated solid;

[0045] 3. Put the obtained solid into a new reaction vessel, add the filtrate from Step 4 in Example 2, make up the filtrate less than 360g with pure water, stir to dissolve, and then cool down to 8°C.

[0046] 4. Add 50wt% sulfuric acid dropwise to the reaction vessel in step 3 at a rate of 20ml / min, control the reaction temperature during and after the dropwise addition to be 8°C, then add 27wt% hydrogen peroxide solution at 2ml / min Continue to add dropwise in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com