Preparation method of D/L-dibenzoyl tartaric acid

A technology of benzoyl tartaric acid and tartaric acid, which is applied in the preparation of carboxylic acid salts, carboxylic acid esters, organic compounds, etc., can solve the problems of environmental pollution and high production costs, and achieve reduced production costs, convenient operation, and shortened process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

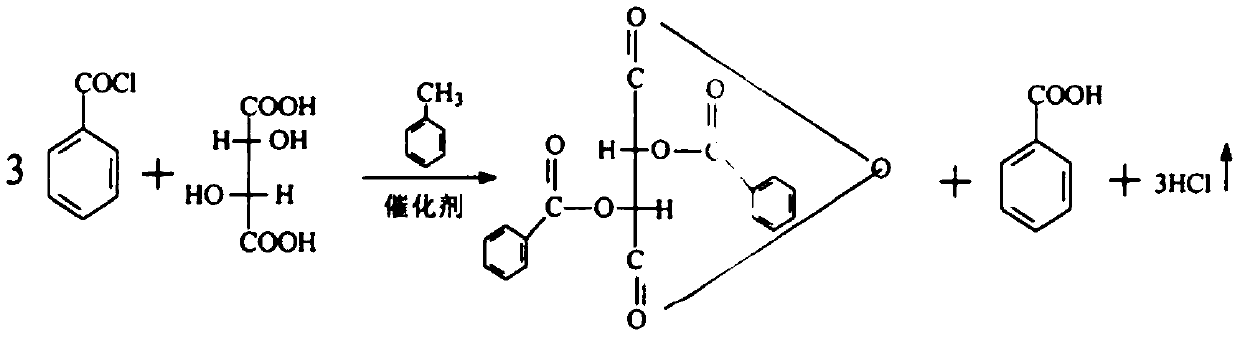

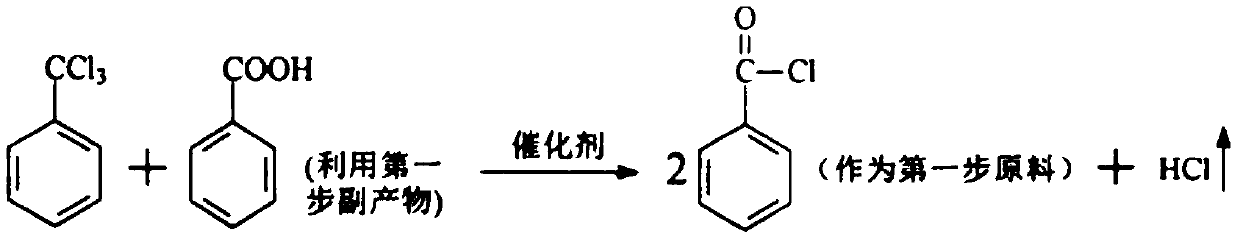

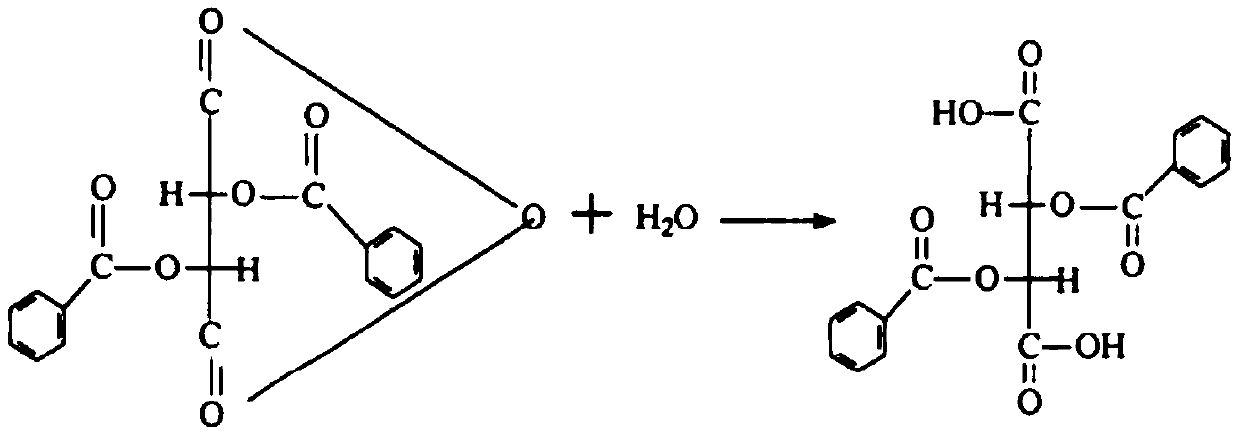

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of D / L-dibenzoyl tartaric acid, comprises the steps:

[0028] Step 1, get D / L-tartaric acid 100g, toluene 150mL and put into reactor, under the condition that stirring speed is 1000r / min, add 3g ferric chloride and 80g benzoyl chloride in reactor, stir After reacting for 20 minutes under the conditions of the reaction kettle, add 60 mL of trichlorobenzyl to the reaction kettle, and then continue to react for 60 minutes after adding; Continue to react for 45 minutes after ℃ to obtain the product mixture;

[0029] Step 2. After the product mixture obtained in step 1 is cooled to room temperature, it is transferred to a centrifuge at a speed of 600 r / min for centrifugation to finally obtain solid D / L-dibenzoyl tartaric acid.

Embodiment 2

[0031] A kind of preparation method of D / L-dibenzoyl tartaric acid, comprises the steps:

[0032] Step 1, get D / L-tartaric acid 100g, toluene 200mL and put into reactor, under the condition that stirring speed is 2500r / min, add the ferric chloride of 6g and the benzoyl chloride of 100g in reactor, stir After reacting for 40 minutes under the conditions of the reaction kettle, add 90 mL of trichlorobenzyl to the reaction kettle, and then continue to react for 50 minutes after adding; Continue to react for 30 minutes after ℃ to obtain the product mixture;

[0033] Step 2. After the product mixture obtained in step 1 is cooled to room temperature, it is transferred to a centrifuge at a speed of 900 r / min for centrifugation to finally obtain solid D / L-dibenzoyl tartaric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com