BaZr0.35Ti0.65O3 epitaxial thin film and preparation method thereof

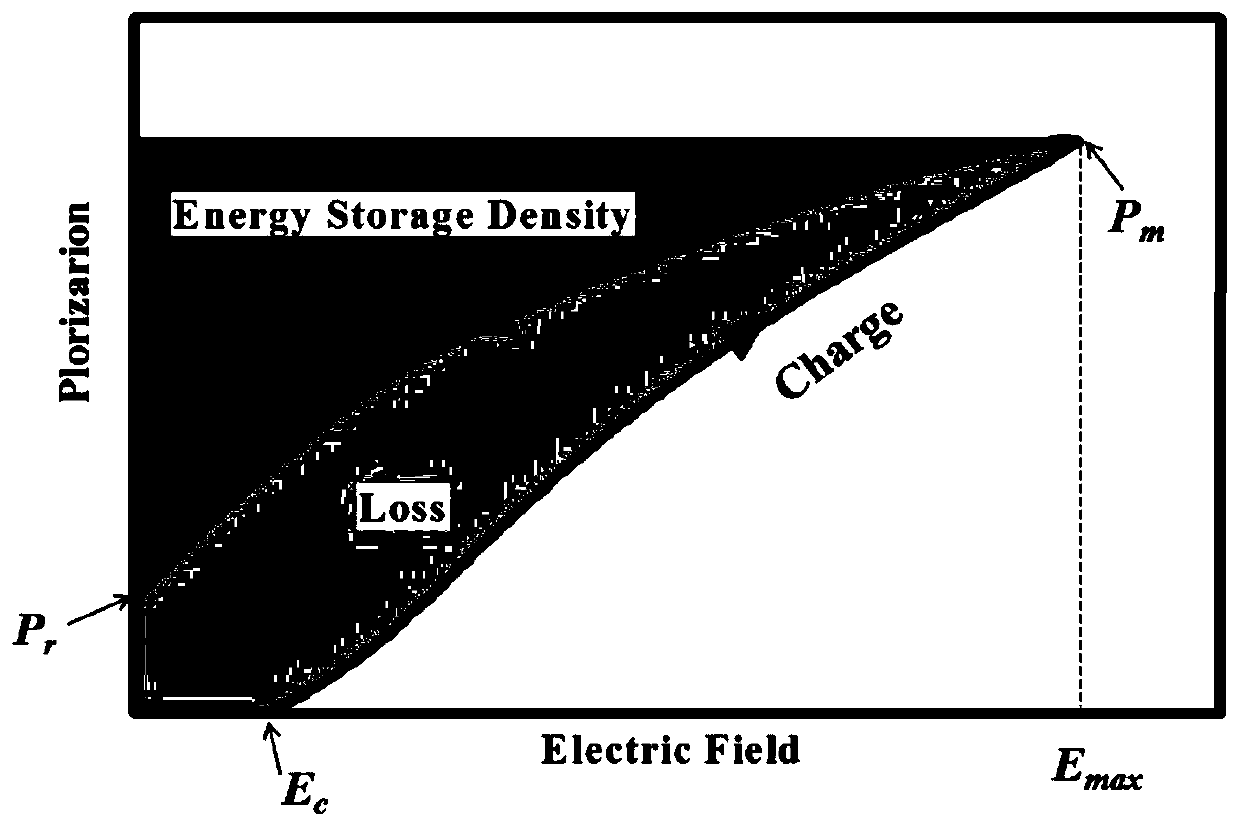

A bazr0.35ti0.65o3, epitaxial thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problem of inability to large energy storage density, achieve excellent thermal stability, high energy storage Effects of density and energy storage efficiency, high insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0037] BaZr of the present invention 0.35 Ti 0.65 o 3 The epitaxial film is a lead-free epitaxial film with high breakdown field strength and excellent wide-temperature energy storage characteristics. It is also a lead-free epitaxial film of the BZT system. The preparation method is as follows:

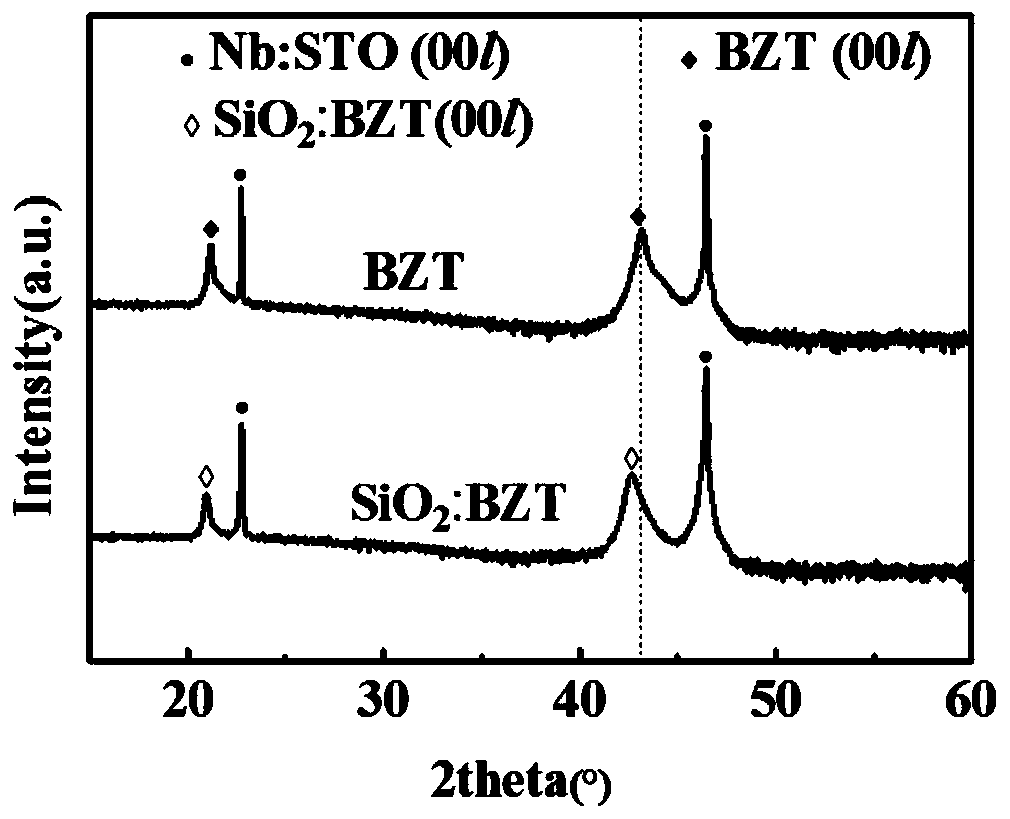

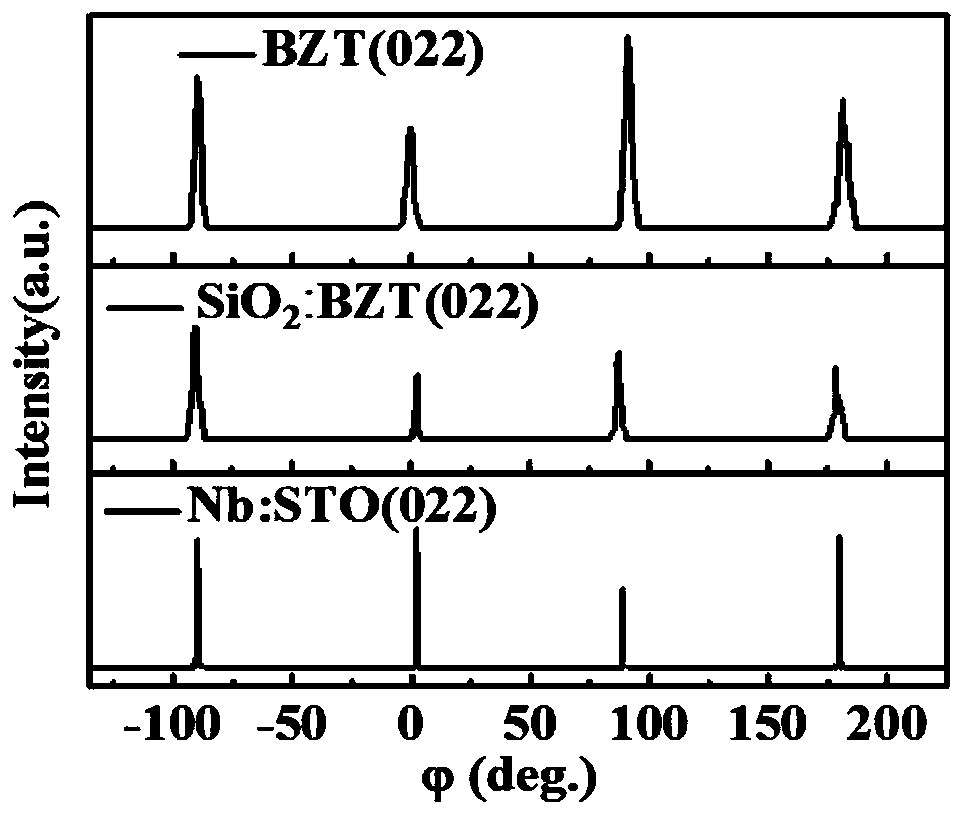

[0038] (1) First, according to the chemical formula BaZr 0.35 Ti 0.65 o 3 (i.e. BZT) and doped with 1% SiO 2 BaZr 0.35 Ti 0.65 o 3 (i.e. SiO 2 : BZT, in mass percent, BaZr 0.35 Ti 0.65 o 3 Medium SiO 2 The doping amount is 1%) to weigh an appropriate amount of 4-5N grade BaCO 3 High purity powder, ZrO 2 High purity powder, TiO 2 and SiO 2 High-purity powder, the mixture of the above four high-purity powders is subjected to ball milling, pre-sintering, granulation, molding and sintering processes, and is prepared into BZT ceramic targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown field strength | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com