Method for preparing reconfigurable ultra-microelectrode with controllable morphology based on magnetic field driving

An ultra-micro electrode, magnetic field driven technology, applied in the direction of measuring electricity, measuring electrical variables, material electrochemical variables, etc., can solve the problems of low resolution and poor repeatability of electrode patterns, and achieves low cost, simple manufacturing method, and equipment. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a method for preparing a reconfigurable ultramicroelectrode with controllable morphology based on magnetic field drive, comprising the following steps:

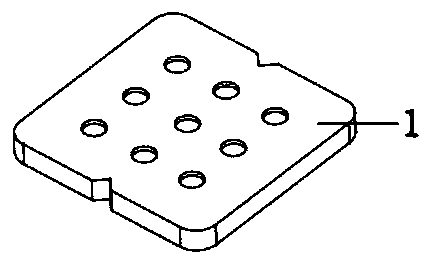

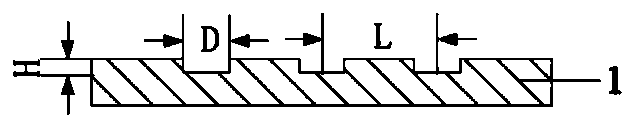

[0026] 1) Referring to Figure 1(a), Figure 1(b) and Figure 1(c), a substrate 1 and a reservoir 2 with a micron groove array are prepared, and a groove array is prepared on the surface of a silicon substrate through a photolithography process to obtain Substrate 1, groove diameter D=5 μm, groove spacing L=10 μm, groove depth H=1 μm;

[0027] 2) Melt 50 μg of 34Bi-66In alloy in an environment of 80°C, add 5 μg of iron powder with a particle size of 100-500nm after it is completely melted, stir evenly, and then vacuum treat it for use;

[0028] 3) Preparation of reconfigurable ultramicroelectrodes 5 with controllable morphology: Referring to Figure 2(a) and Figure 2(b), in an environment of 90°C, first place the substrate 1 in the liquid storage tank 2, A hydrochloric acid solution with a volume concentrati...

Embodiment 2

[0032] Embodiment 2, a method for preparing a shape-controllable reconfigurable ultramicroelectrode based on magnetic field drive, comprising the following steps:

[0033] 1) Referring to Figure 1(a), Figure 1(b) and Figure 1(c), prepare a substrate 1 and a reservoir 2 with a micron groove array, prepare a groove array on the surface of the silicon substrate to obtain a substrate 1, groove Diameter D=10μm, groove spacing L=20μm, groove depth H=3μm;

[0034] 2) Melt 50 μg of 34Bi-66In alloy in an environment of 80°C, add 10 μg of iron powder with a particle size of 100-500 nm after it is completely melted, stir evenly, and then vacuum treat it for use;

[0035] 3) Preparation of reconfigurable ultramicroelectrodes 5 with controllable morphology: Referring to Figure 2(a) and Figure 2(b), in an environment of 90°C, first place the substrate 1 in the liquid storage tank 2, A hydrochloric acid solution with a volume concentration of 17% is added to the tank 2, and a liquid eutecti...

Embodiment 3

[0039] Embodiment 3, a method for preparing a reconfigurable ultramicroelectrode with controllable morphology based on magnetic field drive, comprising the following steps:

[0040] 1) Referring to Figure 1(a), Figure 1(b) and Figure 1(c), prepare a substrate 1 and a reservoir 2 with a micron groove array, prepare a groove array on the surface of the silicon substrate to obtain a substrate 1, groove Diameter D=20μm, groove spacing L=40μm, groove depth H=5μm;

[0041] 2) Melt 100 μg of 34Bi-66In alloy in an environment of 80 ° C, add 30 μg of iron powder with a particle size of 100-500 nm after it is completely melted, stir evenly, and then vacuum treat it for use;

[0042]3) Preparation of reconfigurable ultramicroelectrodes 5 with controllable morphology: Referring to Figure 2(a) and Figure 2(b), in an environment of 90°C, first place the substrate 1 in the liquid storage tank 2, A hydrochloric acid solution with a volume concentration of 20% is added to the tank 2, and a li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com