Novel preparation method of nano-silica microcapsule

A nano-silica and microcapsule technology, applied in the directions of silica and silica, can solve the problems of agglomeration of silica hollow microspheres, different particle sizes, complicated preparation process, etc. The effect of short reaction time and strong reaction controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

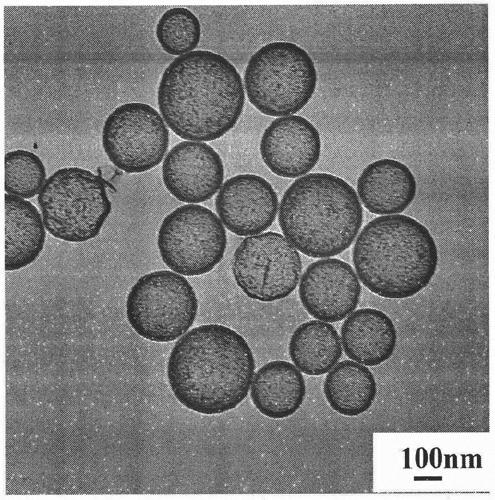

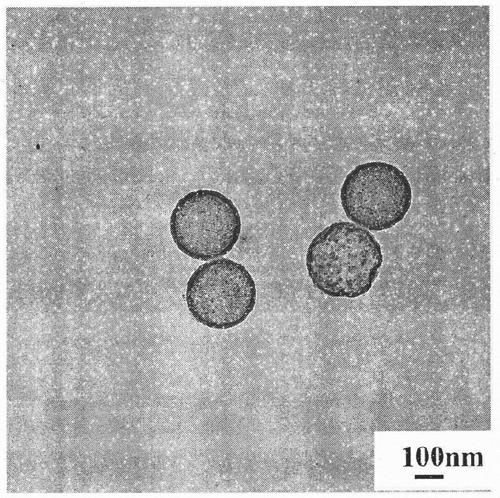

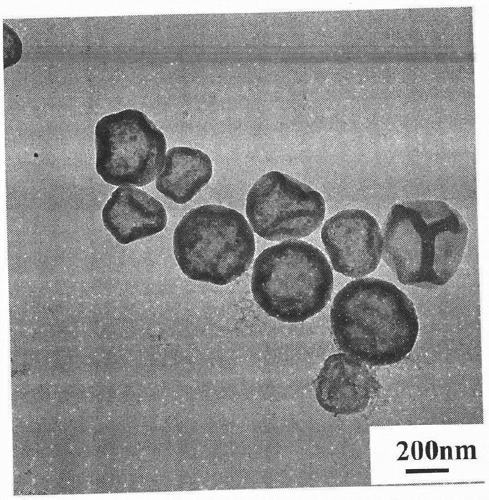

Embodiment 1

[0030] Dissolve 0.8953g disodium hydrogen phosphate and 0.0164g sodium hydroxide in 6ml deionized water to prepare Na 2 HPO 4 12H 2 O-NaOH buffer solution, measure Na 2 HPO 4 12H 2 Add 3ml of O-NaOH buffer solution and 50ml of absolute ethanol into a 100ml round bottom flask at the same time, adjust the speed of the magnetic stirrer to 400-600r / min, and stir for 20min. Add 1ml tetraethyl orthosilicate to the above solution, adjust the speed of the magnetic stirrer to about 1200r / min, stir for 3min, and restore the speed to 400-600r / min, after stirring for 5 hours, the reaction is complete, stop stirring. Pour the completed solution into a centrifuge tube, centrifuge at 10,000r / min for 15min, remove the supernatant, add water and sonicate, repeat several times, wash with water until pH = 7, and obtain a particle size of 310nm and a capsule thickness of 18.5nm nano-SiO 2 Microcapsules.

Embodiment 2

[0032] Dissolve 0.8953g disodium hydrogen phosphate and 0.0444g sodium hydroxide in 6ml deionized water to prepare Na 2 HPO 4 12H 2 O-NaOH buffer solution, measure Na 2 HPO 4 12H 2 Add 3ml of O-NaOH buffer solution and 50ml of absolute ethanol into a 100ml round bottom flask at the same time, adjust the speed of the magnetic stirrer to 400-600r / min, and stir for 20min. Add 1ml tetraethyl orthosilicate to the above solution, adjust the speed of the magnetic stirrer to about 1200r / min, stir for 3min, and restore the speed to 400-600r / min, after stirring for 5 hours, the reaction is complete, stop stirring. Pour the solution that has completed the reaction into a centrifuge tube, centrifuge at a speed of 10,000r / min for 15 minutes, remove the supernatant, add water and sonicate, repeat several times, wash with water until pH = 7, and obtain a particle size of 248nm and a capsule thickness of 14nm. nano-SiO 2 Microcapsules.

Embodiment 3

[0034] Dissolve 0.8953g disodium hydrogen phosphate and 0.0164g sodium hydroxide in 6ml deionized water to prepare Na 2 HPO 4 12H 2 O-NaOH buffer solution, measure Na 2 HPO 4 12H 2 Add 6ml of O-NaOH buffer solution and 50ml of absolute ethanol into a 100ml round bottom flask at the same time, adjust the speed of the magnetic stirrer to 400-600r / min, and stir for 20min. Add 1ml tetraethyl orthosilicate to the above solution, adjust the speed of the magnetic stirrer to about 1200r / min, stir for 3min, and restore the speed to 400-600r / min, after stirring for 5 hours, the reaction is complete, stop stirring. Pour the solution that has completed the reaction into a centrifuge tube, centrifuge at a speed of 10,000r / min for 15 minutes, remove the supernatant, add water and sonicate, repeat several times, wash with water until pH = 7, and obtain a particle size of 391nm and a capsule thickness of 31nm. nano-SiO 2 Microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com