Low-temperature preparation method of AlON (aluminum oxynitride) transparent ceramic

A transparent ceramic, low temperature technology, which is applied in the preparation of high transmittance aluminum oxide nitride ceramics and the preparation of transparent ceramics, achieves the effects of high product quality, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, a low-temperature preparation method of AlON transparent ceramics includes the following steps:

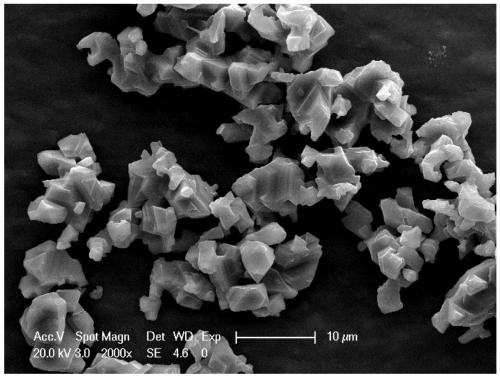

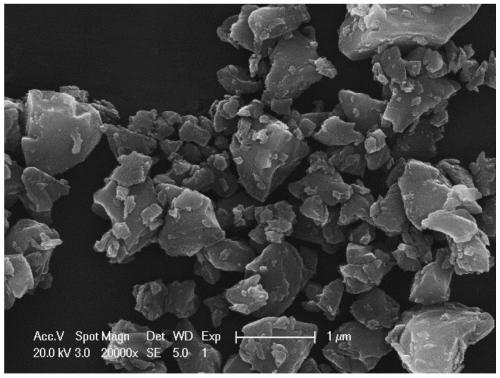

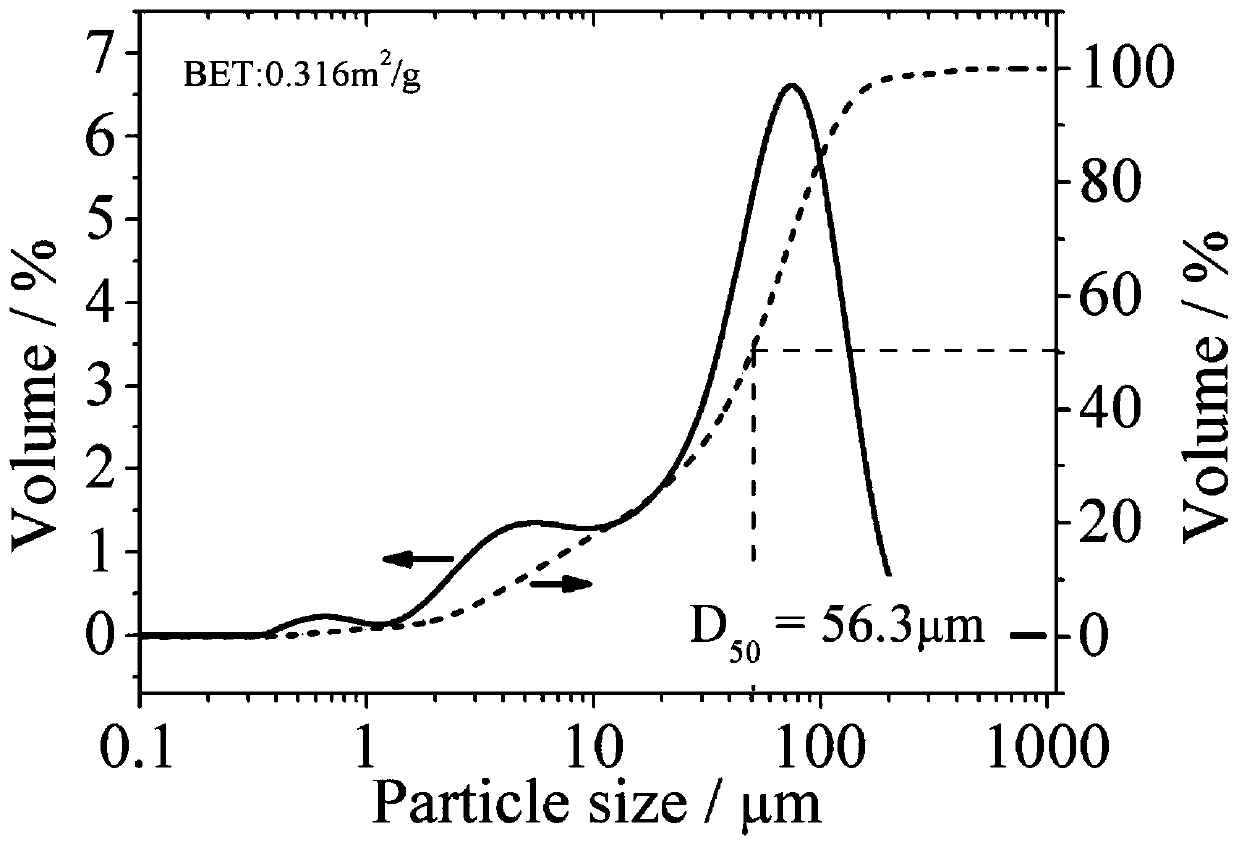

[0044] a. Using high-purity AlON powder as raw material, weigh 30g of AlON powder and put it into an alumina ball mill jar, put 600g of alumina balls with a diameter of 5mm, and add absolute ethanol with 0.8 times the powder mass as the ball milling medium; The purity of the dehydrated ethanol is not lower than the purity of analytical grade; add dehydrated ethanol to make a slurry, and the high-purity AlON powder is made of Al 2 o 3 / C mixture synthesized by carbothermal reduction method, the powder purity is 99%, the median particle size is 56.3μm, and the specific surface area (BET) is 0.316m 2 / g; Put the prepared ball mill tank into the omnidirectional planetary ball mill and mill it at 250r / min for 24 hours to crush and modify the AlON powder. After the ball mill is broken, put the slurry in the container, and then Put the ball-milled slurry into...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, especially in that:

[0055] In this embodiment, a low-temperature preparation method of AlON transparent ceramics includes the following steps:

[0056] a. This step is the same as in Embodiment 1;

[0057] b. Weigh 15g of the submicron single-phase AlON powder obtained after ball milling in the step a and pack it into a polytetrafluoroethylene tank, then weigh the 0.4% MgO sintering aid of the submicron single-phase AlON powder quality Put the agent into a polytetrafluoroethylene tank for mixing to obtain a mixed powder, then put 150.9 g of alumina balls with a diameter of 5 mm, use absolute ethanol as the ball milling medium, and add anhydrous ethanol with 1 times the powder mass as the ball milling medium , put the prepared ball mill tank into the omni-directional planetary ball mill and mill at 250r / min for 12 hours, put the slurry in the container after the ball mill is mixed, put it in the drying oven for 20...

Embodiment 3

[0065] This embodiment is basically the same as the previous embodiment, and the special features are:

[0066] In this embodiment, a low-temperature preparation method of AlON transparent ceramics includes the following steps:

[0067] a. This step is the same as in Embodiment 1;

[0068] b. Weigh 30g of the submicron single-phase AlON powder obtained after ball milling in step a and put it into a nylon tank, then weigh the 0.6% MgO sintering aid of the submicron single-phase AlON powder quality and put it into Mix in a nylon tank to obtain a mixed powder, put 301.8g of alumina balls with a diameter of 5mm, use absolute ethanol as the ball milling medium, add absolute ethanol with 1 times the powder mass as the ball milling medium, and mill the prepared materials Put the tank into an all-round planetary ball mill and mill it at 250r / min for 12 hours; after the ball mill is mixed, put the slurry in a container, put it in a drying oven for 20 hours at 60°C, and take out the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com