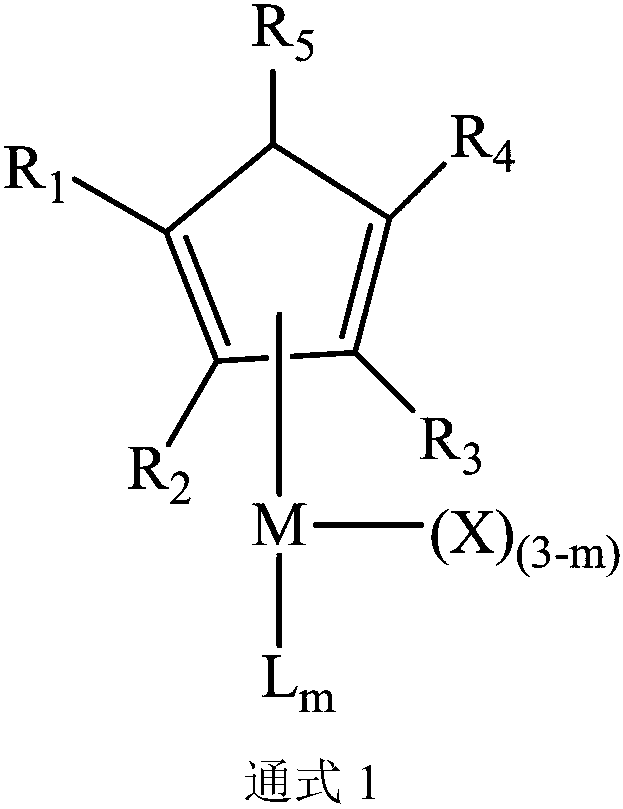

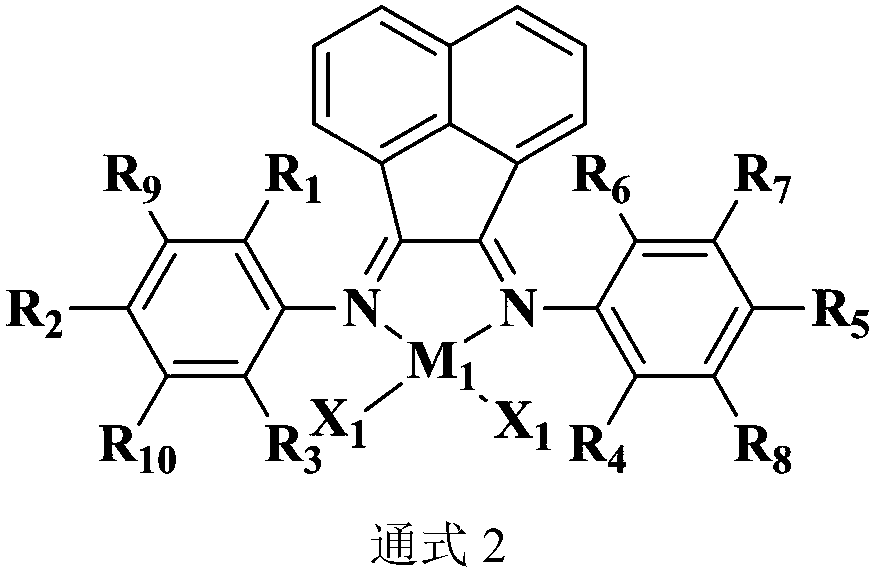

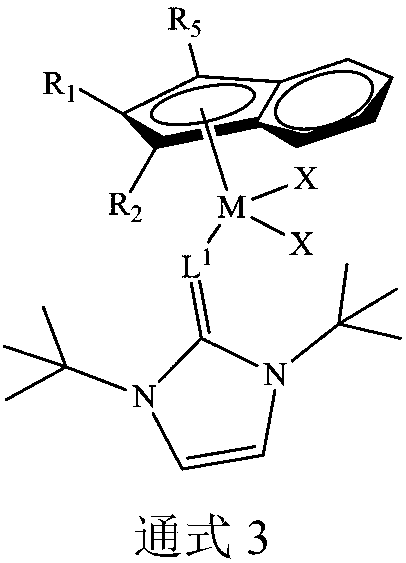

Catalyst composition used for ethylene polymerization, and application thereof

A technology of ethylene polymerization and catalyst, which is applied in the field of catalyst composition, and can solve the problems that the composition of polymer blocks cannot be changed, and the difference in polymer structure and properties is not obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] At high temperature, vacuumize the 1L high-pressure stainless steel polymerization kettle, and replace ethylene gas three times near the polymerization temperature (60°C). Under ethylene atmosphere, 500 mL of toluene solvent was added. With the inflow of toluene solvent, cocatalyst (8ml concentration is the toluene solution of 1.53M methylalumoxane) and chain shuttling agent (0.8ml concentration is the toluene solution of 1.5M diethylzinc) to add through syringe; Catalyst A (6 ml of a toluene solution with a concentration of 1.0 μM) and catalyst B (2 ml of a toluene solution with a concentration of 1.0 μM) were added by syringe. Quickly feed ethylene gas and maintain the pressure of 1.0Mpa in the polymerization tank, and the monomer is polymerized at 60°C for 30 minutes. The temperature of the kettle was lowered to about room temperature, and the polymer solution was discharged and treated with acidified ethanol. After that, it was filtered with suction, dried in vacu...

Embodiment 2

[0092] At high temperature, vacuumize the 1L high-pressure stainless steel polymerization kettle, and replace ethylene gas three times near the polymerization temperature (60°C). Under ethylene atmosphere, 500 mL of toluene solvent was added. Along with the inflow of toluene solvent, cocatalyst (8ml concentration is the toluene solution of 1.53M methylalumoxane) and chain shuttling agent (1.6ml concentration is the toluene solution of 1.5M diethylzinc) to add by syringe; Catalyst A (6 ml of 1.0 μM toluene solution) and catalyst B (2 ml of 1.0 μM toluene solution) were added via syringe. Quickly feed ethylene gas and maintain the pressure of 1.0Mpa in the polymerization tank, and the monomer is polymerized at 60°C for 30 minutes. The temperature of the kettle was lowered to about room temperature, and the polymer solution was discharged and treated with acidified ethanol. After that, it was filtered with suction, dried in vacuum and weighed for the corresponding test in the l...

Embodiment 3

[0094] At high temperature, vacuumize the 1L high-pressure stainless steel polymerization kettle, and replace ethylene gas three times near the polymerization temperature (60°C). Under ethylene atmosphere, 500 mL of toluene solvent was added. With the inflow of toluene solvent, cocatalyst (8ml concentration is the toluene solution of 1.53M methylalumoxane) and chain shuttling agent (1.6ml concentration is the toluene solution of 1.5M diethylzinc) to add through syringe; Catalyst A (4 ml of a toluene solution with a concentration of 1.0 μM) and catalyst B (4 ml of a toluene solution with a concentration of 1.0 μM) were added by syringe. Quickly feed ethylene gas and maintain the pressure of 1.0Mpa in the polymerization tank, and the monomer is polymerized at 60°C for 30 minutes. The temperature of the kettle was lowered to about room temperature, and the polymer solution was discharged and treated with acidified ethanol. After that, it was filtered with suction, dried in vacu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com