Method for producing conductive screw

A screw and mold technology, applied in the field of conductive screw production, can solve the hidden dangers of 6 major broken knives in deep holes, and achieve the effect of reducing hidden dangers of deformation and cracking, preventing knife breaking problems, and reducing deformation and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] The method for producing a conductive screw, the specific steps are as follows:

[0035] A. Casting:

[0036] 1. Raw material: molten metal, graphite rod;

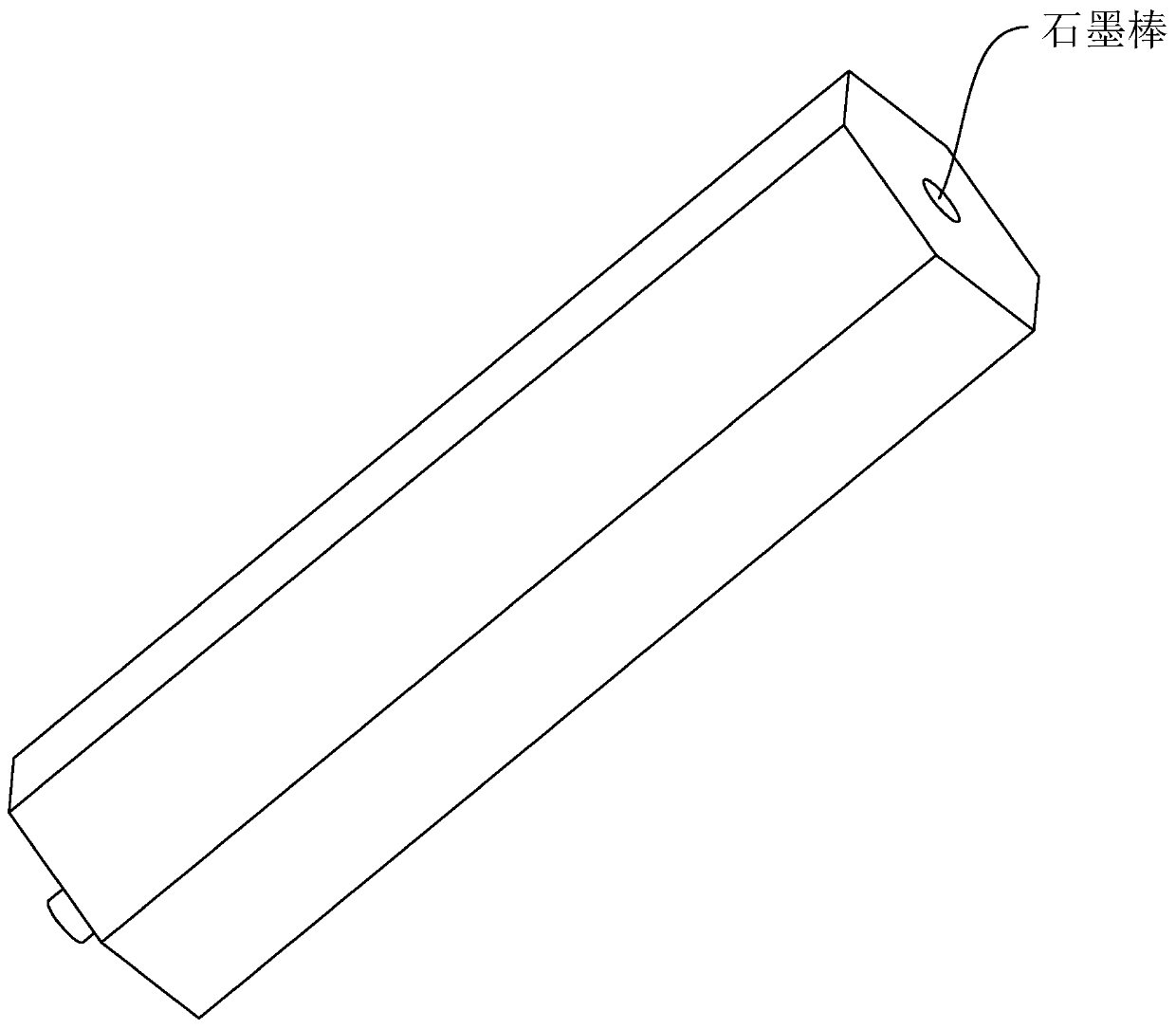

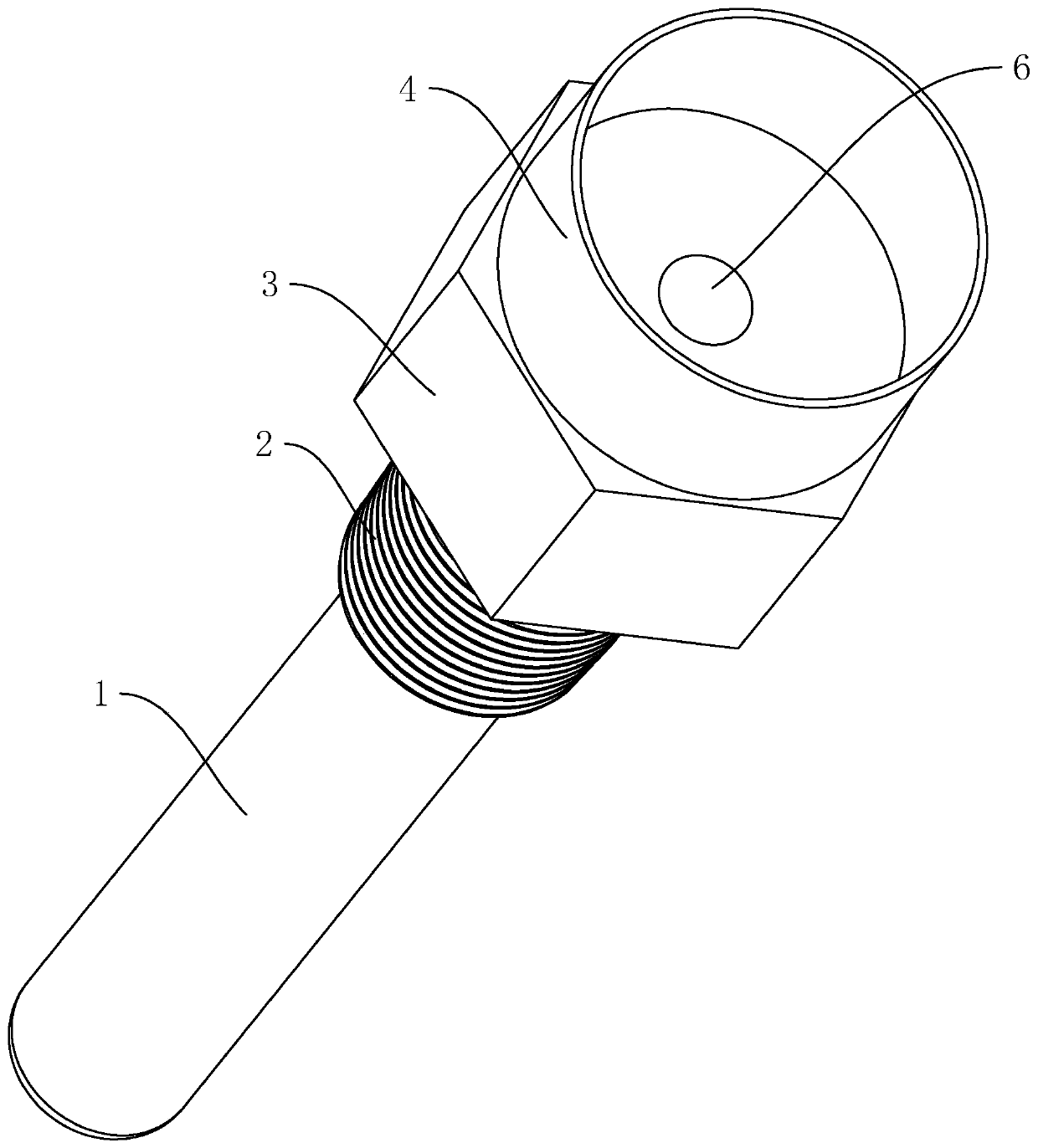

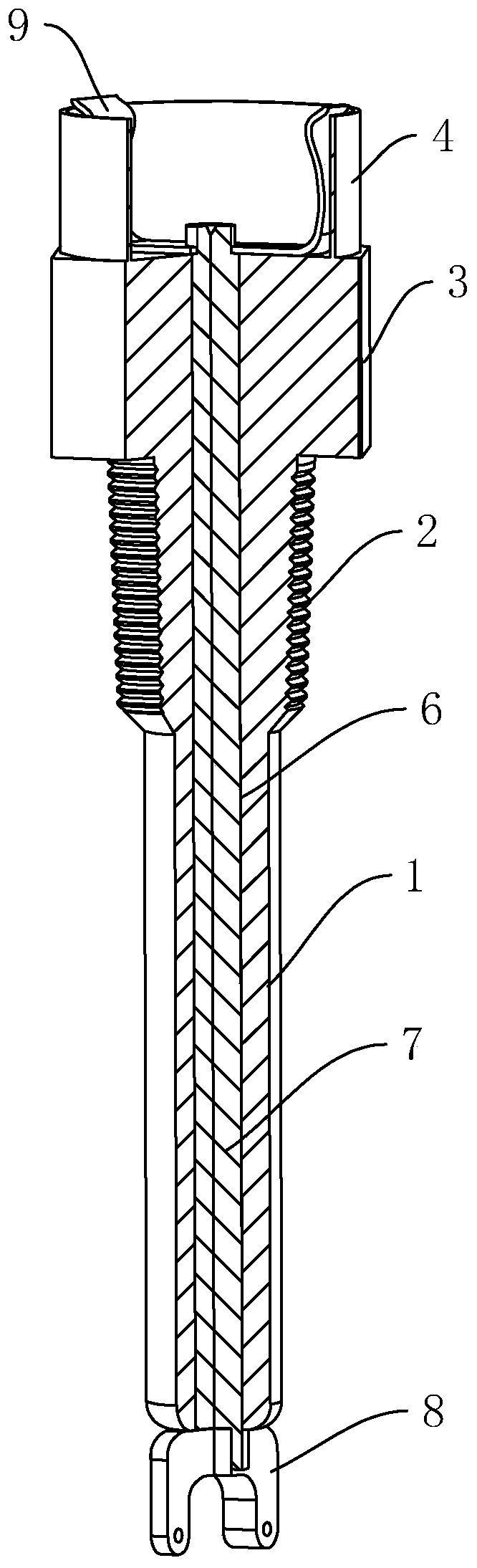

[0037] 2. Equipment: casting press, mold 10 (marked on Figure 4 );

[0038] 3. Workflow: such as figure 1 , Figure 4 As shown, after the graphite rod is vertically fixed in the mold 10, the molten metal is injected into the mold 10, and pressure is applied to the mold by a press, so that the blank is formed under a pressure environment;

[0039] 4. Technical effect: The graphite rod is preset in the blank, so that the deep hole can be formed only by taking out the graphite rod. The specific method of taking out the graphite rod is to press it out by a press, or crush it by a drilling machine.

[0040] B. Rough processing:

[0041] 1. Equipment: lathe, hexagonal machine, tapping machine; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com