Method for preventing fouling of wastewater flow-limiting device of water purifier and water purifier

A technology of a current limiting device and a water purification device, which is applied in the field of water treatment, can solve problems such as the inability to effectively solve the waste water ratio blocking in the water purifier, and achieve the effect of not damaging the service life and slowing down the waste water ratio blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

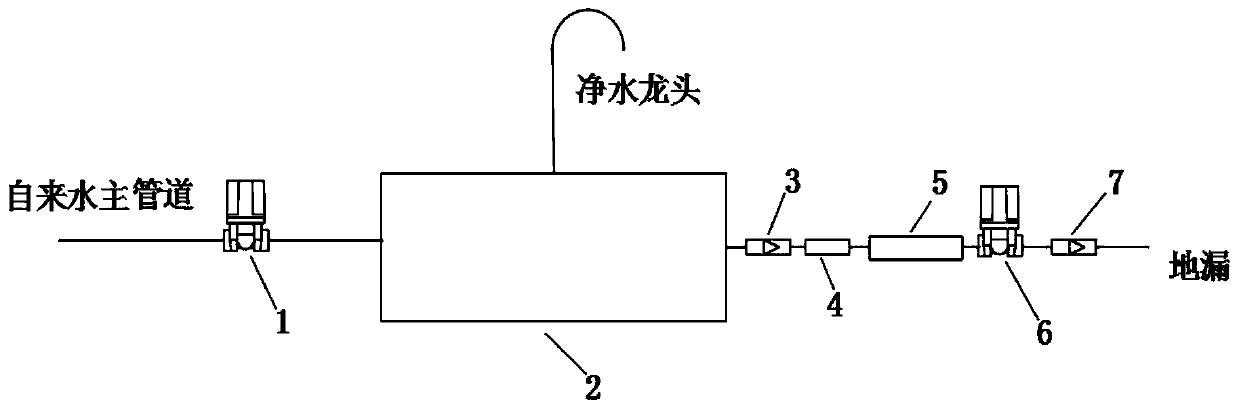

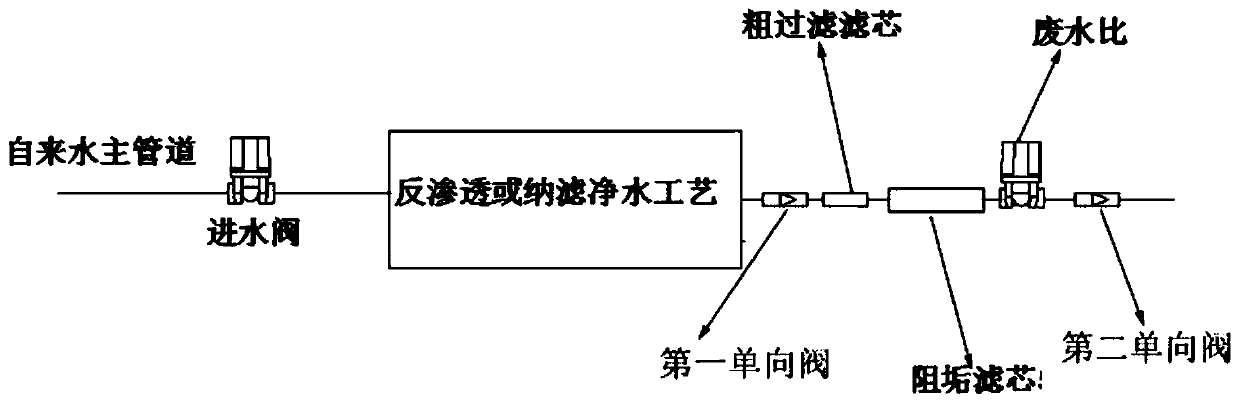

[0059] The water purifier provided in this embodiment includes a water inlet valve, a water purification device, a first one-way valve, a filter device, a scale prevention device, a waste water ratio device and a second one-way valve connected in sequence.

[0060] Among them, the water inlet valve is connected to the tap water pipeline; the water purification device is a reverse osmosis water purification device, and the filter device is built with pp cotton and activated carbon; the scale inhibition device is a polycarboxylic acid scale inhibition dispersant.

[0061] After using the water purifier, after the tap water is pre-filtered, after entering the water through the water inlet valve, the water purification device purifies the water quality to obtain purified water, and the remaining waste water passes through the first one-way valve, and then passes through post-filtering and Anti-scaling filter treatment.

Embodiment 2

[0063] The water purifier provided in this embodiment includes a water inlet valve, a water purification device, a first one-way valve, a filter device, a scale prevention device, a waste water valve device and a second one-way valve connected in sequence.

[0064] Among them, the water inlet valve is connected to the tap water pipeline; the water purification device is a reverse osmosis water purification device, and the filter device has a built-in ultra-micro filter element; the scale inhibition device is RO scale inhibitor.

[0065] After using the water purifier, after the tap water is pre-filtered, after entering the water through the water inlet valve, the water purification device purifies the water quality to obtain purified water, and the remaining waste water passes through the first one-way valve, and then passes through post-filtering and Anti-scaling filter treatment.

Embodiment 3

[0067] The water purifier provided in this embodiment includes a water inlet valve, a water purification device, a first one-way valve, a filter device, a scale prevention device, a waste water ratio device and a second one-way valve connected in sequence.

[0068] Among them, the water inlet valve is connected to the tap water pipeline; the water purification device is a reverse osmosis water purification device, and the filter device has a built-in microfiltration filter element; the scale inhibition device is RO scale inhibitor.

[0069] After using the water purifier, after the tap water is pre-filtered, after entering the water through the water inlet valve, the water purification device purifies the water quality to obtain purified water, and the remaining waste water passes through the first one-way valve, and then passes through post-filtering and Anti-scaling filter treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com