A kind of preparation method of high-strength fastener

A fastener and high-strength technology, applied in the field of parts manufacturing, can solve the problems of deterioration of material manufacturability, increase of alloy elements, increase of material cost, etc., to reduce the cost of raw materials and the difficulty of obtaining, and avoid the effect of adding a large amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

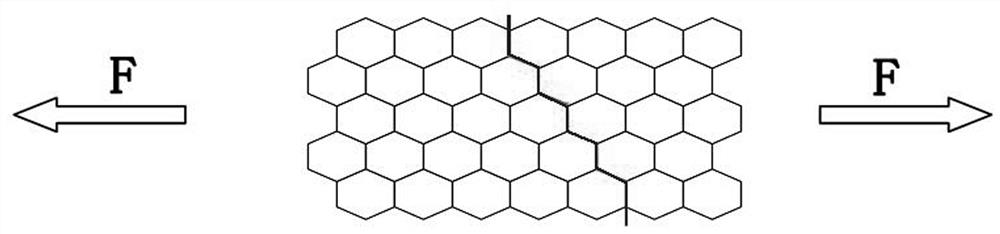

Image

Examples

preparation example Construction

[0025] A method for preparing high-strength fasteners. The fastener raw materials are subjected to heat treatment and cold deformation to obtain fasteners with an upper limit of tensile strength of 1400 MPa and a performance level of 10.9-12.9. The specific preparation steps are as follows:

[0026] Step 1. Perform quenching and high-temperature tempering heat treatment on the fastener raw material, and the tensile strength of the fastener raw material after heat treatment is Rm≥650MPa;

[0027] Step 2, using cold drawing or cold rolling process to cold deform the fastener raw material after the heat treatment in step 1 with an area reduction rate of more than 60%, to obtain a fastener blank;

[0028] Step 3: Perform thread processing or / surface treatment on the fastener blank obtained in step 2 to obtain a fastener whose tensile strength is greater than 1300 MPa.

[0029] The general surface treatment process can be carried out with the process operating temperature below the...

Embodiment 1

[0036] Commercially available 35CrMo φ40 steel bar is used, the chemical composition of the material: C: 0.37%, Si: 0.22%, Mn: ≤0.56%, S: ≤0.005%, P: 0.013%, Cr: 0.92%, Mo: 0.18%, and the rest for iron.

[0037] A method for preparing high-strength fasteners is:

[0038] Step 1. The steel bar is subjected to 860°C quenching + 640°C tempering heat treatment. After the heat treatment, the surface is shot blasted and textured to remove the surface scale. At this time, the tensile strength of the steel bar is Rm=785MPa.

[0039] Step 2. Use the drawing process to draw the bar in 6 passes to φ22mm, and the dimensions of each drawing pass are φ40-φ36.5-φ32.8-φ29.6-φ26.8-φ24.2 -φ22. The total area reduction rate is 69.75%.

[0040] Step 3, using the thread rolling process to roll the drawn bar material into an M24 thread, and manufacture it into an M24 screw fastener.

[0041] Step 4, surface degreasing, phosphating treatment, and dehydrogenation treatment at 200°C / 12h.

[0042]...

Embodiment 2

[0047] Commercially available 34CrNi3MoV φ120 steel bar material is used, the material chemical composition: C: 0.352%, Si: 0.234%, Mn: 0.305%, S: ≤0.005%, P: 0.0060%, Cr: 1.17%, Ni: 2.93%, Mo : 0.322%, V: 0.118%.

[0048] Step 1, the steel rod is subjected to 900°C quenching + 670°C tempering heat treatment, and the tensile strength of the steel rod at this time is Rm=823MPa.

[0049] Step 2: Heat the bar to a temperature below the recrystallization temperature of 350°C, and roll it into a φ55mm bar through 9 passes with a three-roll bar mill, with an area reduction rate of 79%.

[0050] Step 3. Use centerless turning to turn the bar to φ52.5, and use centerless grinding to cut the outer circle of the bar to the diameter of the blank before M56 screw rolling. Use the thread rolling process to roll the bar into M56 thread and manufacture it into M56 screw fastener.

[0051] Test the mechanical properties of the screw, and the tensile strength of the screw is σb=1365MPa. Mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com